Method for preparing antibacterial wound dressing with high chitosan content by means of electrostatic spinning

A technology of wound dressing and chitosan, which is applied in the directions of pharmaceutical formula, rayon manufacturing, textiles and paper making, etc., can solve the problem that it is difficult to obtain continuous chitosan nanofibers, and achieve good antibacterial effect and biocompatibility, Reproducible results with great application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] First prepare nano-silver solution, the preparation method of nano-silver solution is:

[0042] A. Distilled water is adjusted to pH 11.5 with NaOH;

[0043] B, preparation mass percentage concentration is the carboxymethyl chitosan solution of 0.2%, measures 10ml solution in transparent glass bottle;

[0044] C. Set the temperature at 70°C, stir at 700rpm, add 1.7M AgNO dropwise 3 until the color of the solution turns yellow;

[0045] D. Take it out after heating and stirring for 1 hour, and keep it away from light for later use.

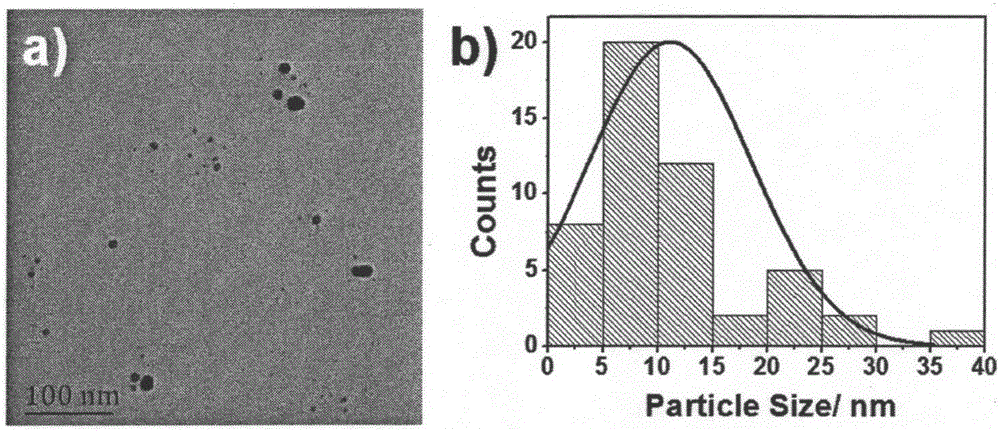

[0046] The transmission electron microscope image of the prepared nano-silver solution is as follows: figure 1 Shown in (a), the particle size distribution of prepared nano-silver solution is as follows figure 1 (b) shown.

[0047] The preparation method of electrospun antibacterial wound dressing with high chitosan content is as follows:

[0048] (1) Nano-silver solution, dimethyl sulfoxide, acetic acid, and surfactant are made into a m...

Embodiment 2

[0054] (1) Deionized water, dimethyl sulfoxide, acetic acid, and surfactant are formulated into a mixed solvent according to the ratio of 290:35:8:1 for use;

[0055] (2) Take by weighing 0.42g of chitosan and 0.18g of ultra-high molecular weight polyethylene oxide respectively, join in the above-mentioned mixed solvent, place the solution on a heatable magnetic stirrer and stir overnight;

[0056] (3) The next day, the solution was ultrasonically oscillated, and then heated in an oven above 50 degrees for about 15 minutes;

[0057] (4) The electrospinning parameters were set as the spinning voltage was 15kV, the distance between the needle and the receiving plate was 15cm, the propulsion speed of the propulsion pump was 0.15mm / h, and the spinning ambient temperature was 40°C.

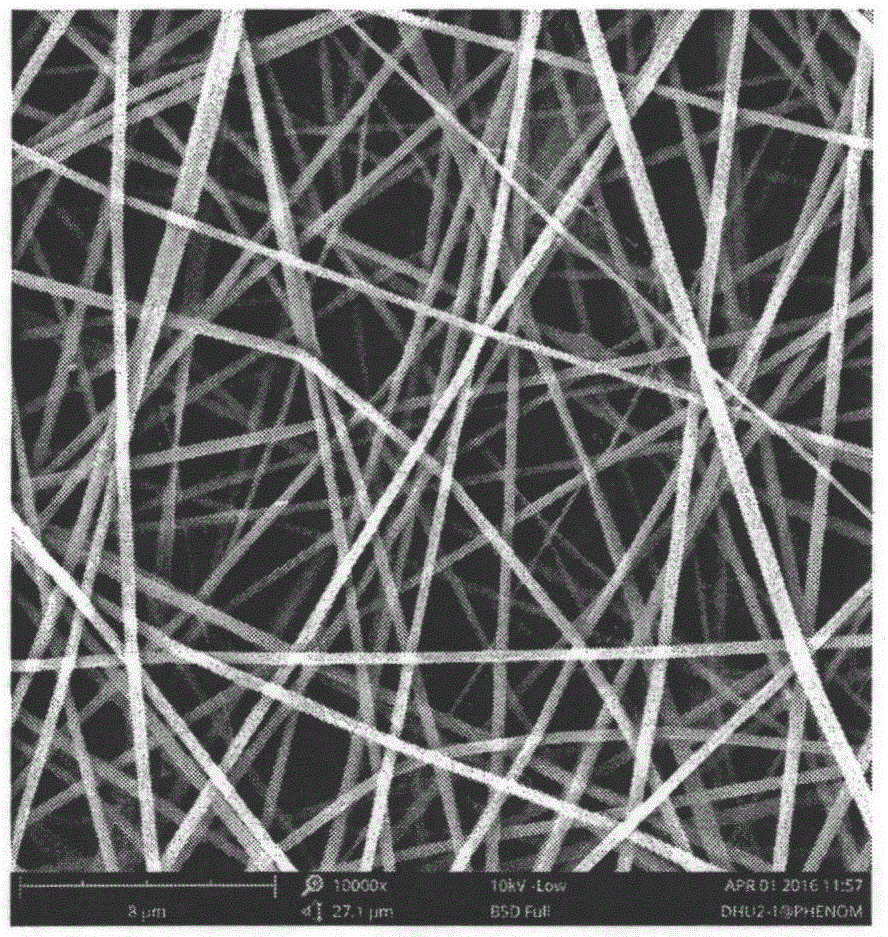

[0058] The receiving device is fabricated according to the size of the desired dressing and electrospun. A chitosan dressing without nano-silver with good fiber morphology can be obtained. Figure 4 ...

Embodiment 3

[0060] (1) Deionized water, dimethyl sulfoxide, acetic acid, and surfactant are formulated into a mixed solvent according to the ratio of 290:35:8:1 for use;

[0061] (2) Take the chitosan of 0.30g and the low molecular weight polyethylene oxide of 0.30g respectively, join in the above-mentioned mixed solvent, place the solution on a heatable magnetic stirrer and stir overnight;

[0062] (3) The next day, the solution was ultrasonically oscillated, and then heated in an oven above 50 degrees for about 15 minutes;

[0063] (4) The electrospinning parameters were set as the spinning voltage was 15kV, the distance between the needle and the receiving plate was 15cm, the propulsion speed of the propulsion pump was 0.15mm / h, and the spinning ambient temperature was 40°C.

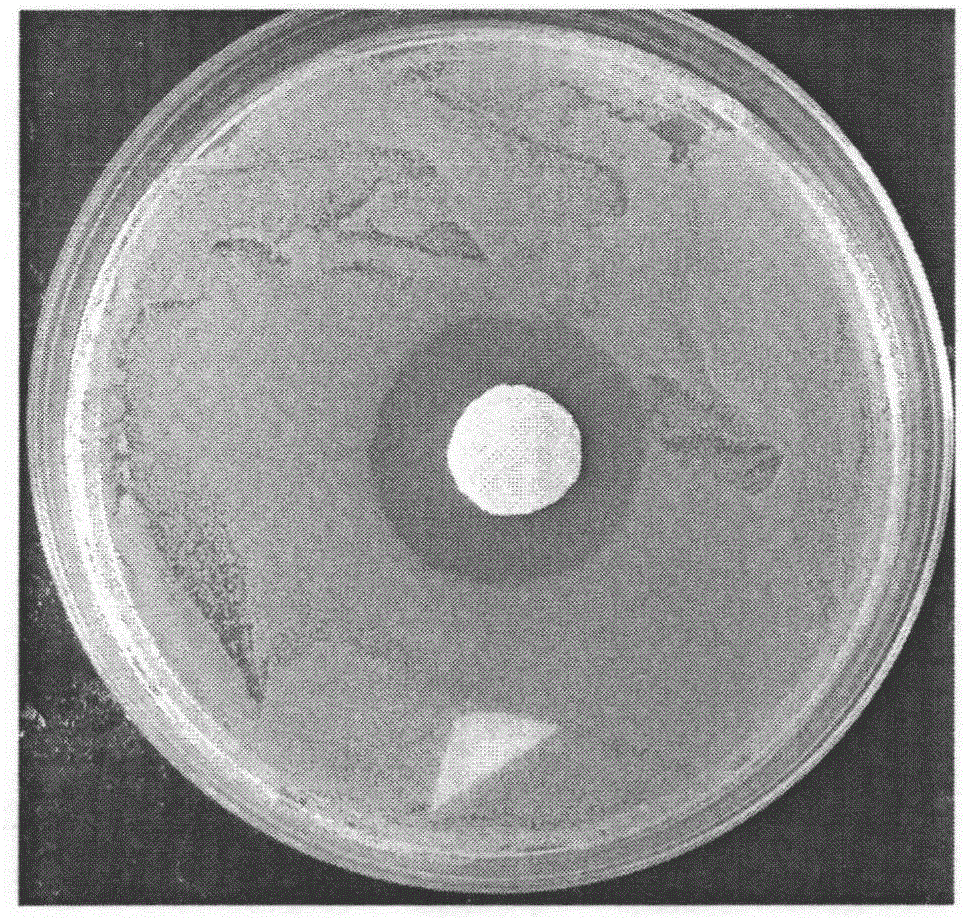

[0064] The receiving device is fabricated according to the size of the desired dressing and electrospun. Image 6 The scanning electron microscope picture of the dressing shows that a lot of beaded structures ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com