Preparation method of ferromagnetic nanowire array

A nanowire array and ferromagnetic technology, applied in the field of preparation of ferromagnetic nanowire arrays, can solve the problem of not preparing ferromagnetic nanowire arrays and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

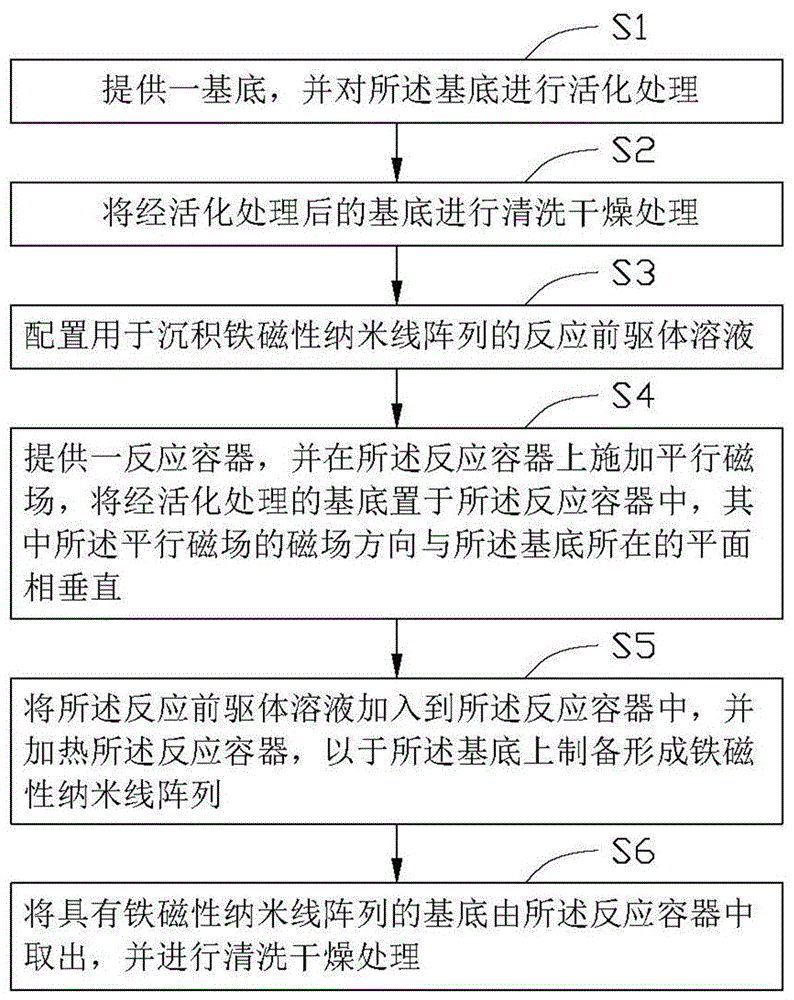

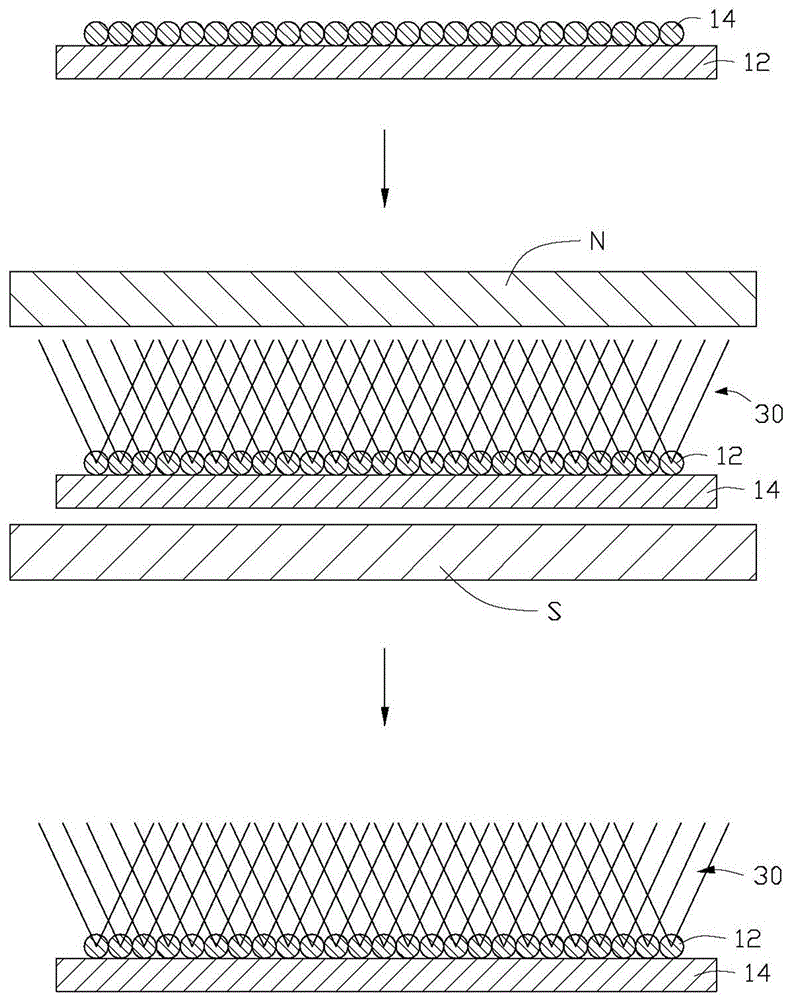

[0029] Please also refer to figure 1 and figure 2 , an embodiment of the present invention provides a method for preparing a ferromagnetic nanowire array, which includes the following steps:

[0030] S1: providing a substrate 12 and performing an activation treatment on the substrate 12 . Specifically, in the illustrated embodiment, the substrate 12 is activated by depositing an activation seed layer 14 on the substrate 12, wherein the activation seed layer 14 includes a plurality of metal nanoparticles. The metal nanoparticles are one or more of palladium nanoparticles, gold nanoparticles, platinum nanoparticles, iridium nanoparticles, rhodium nanoparticles, and ruthenium nanoparticles.

[0031] The material of the base 12 can be selected according to actual needs, and it can be a flexible base or a rigid base. The material of the substrate 12 is one or more of metal foil, polymer film, carbon material film, metal oxide film, ceramic film and other film materials. The meta...

Embodiment approach 1

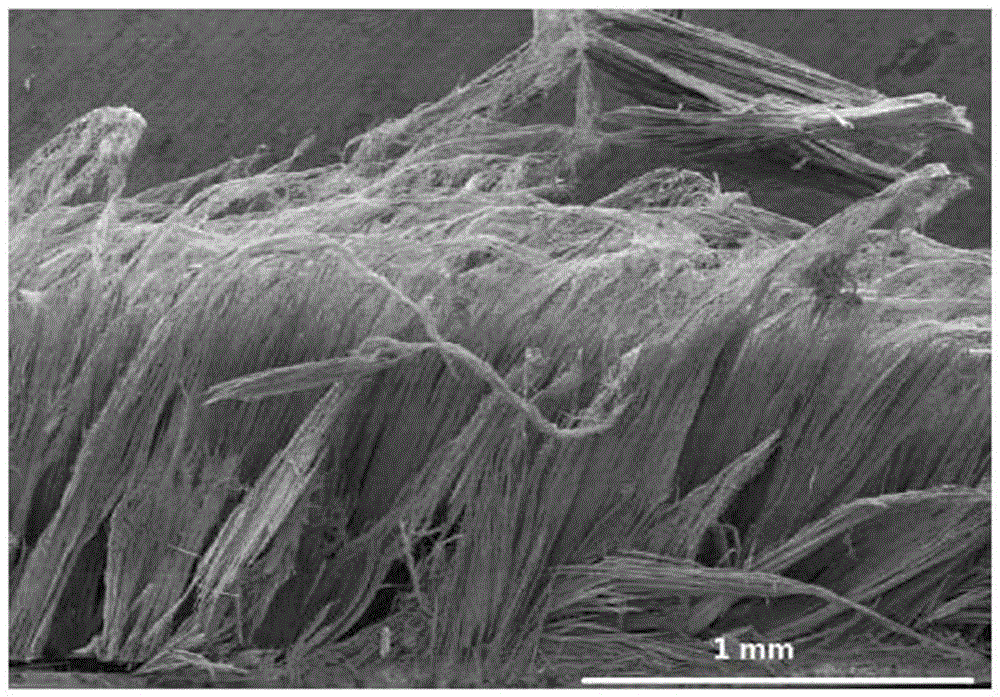

[0043] A nickel nanowire array is prepared and formed on a titanium foil as a substrate.

[0044] The titanium foil was cleaned and dried, wherein the titanium foil was cleaned with deionized water and absolute ethanol respectively, and dried in an oven at 70° C. for 2 hours.

[0045] Configure an activated precursor solution for depositing a palladium (Pd) metal activated seed layer. 0.05 mol / L PdCl 2 Mix with a small amount of concentrated hydrochloric acid. Preferably for the above PdCl 2 The mixed solution was subjected to ultrasonic treatment until the mixed solution presented a uniform reddish-brown color. Take 35 mL of the above mixed solution, add 15 mL of concentrated ammonia water, and 0.1 mL of 85% hydrazine hydrate to obtain the activated precursor solution.

[0046] After stirring the activated precursor solution evenly, place the titanium foil in the activated precursor solution, and perform chemical deposition at 60°C to obtain the palladium metal activated ...

Embodiment 2

[0053] Cobalt ferromagnetic nanowire arrays were prepared and formed using copper foil as a substrate.

[0054] The copper foil was cleaned and dried, wherein the titanium sheet was cleaned with deionized water and absolute ethanol respectively, and the copper foil was dried in an oven at 70° C. for 2 hours.

[0055] Configure an activated precursor solution for depositing a palladium (Pd) metal activated seed layer. 0.05 mol / L PdCl 2 Mix with a small amount of concentrated hydrochloric acid. Preferably for the above PdCl 2 The mixed solution was subjected to ultrasonic treatment until the mixed solution presented a uniform reddish-brown color. Take 35 mL of the above mixed solution, add 15 mL of concentrated ammonia water, and 0.1 mL of 85% hydrazine hydrate to obtain the activated precursor solution.

[0056] After stirring the activated precursor solution evenly, place the copper foil in the activated precursor solution, and perform chemical deposition at 60°C to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com