A kind of method that chlorination by-product hydrochloric acid is used for coating of titanium dioxide

A technology for by-producing hydrochloric acid and titanium dioxide, which is applied in chemical instruments and methods, dyeing low-molecular-weight organic compound treatment, inorganic pigment treatment, etc. Competition and other issues, to achieve the effect of improving chalking resistance, reducing photochemical activity, and improving chalking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

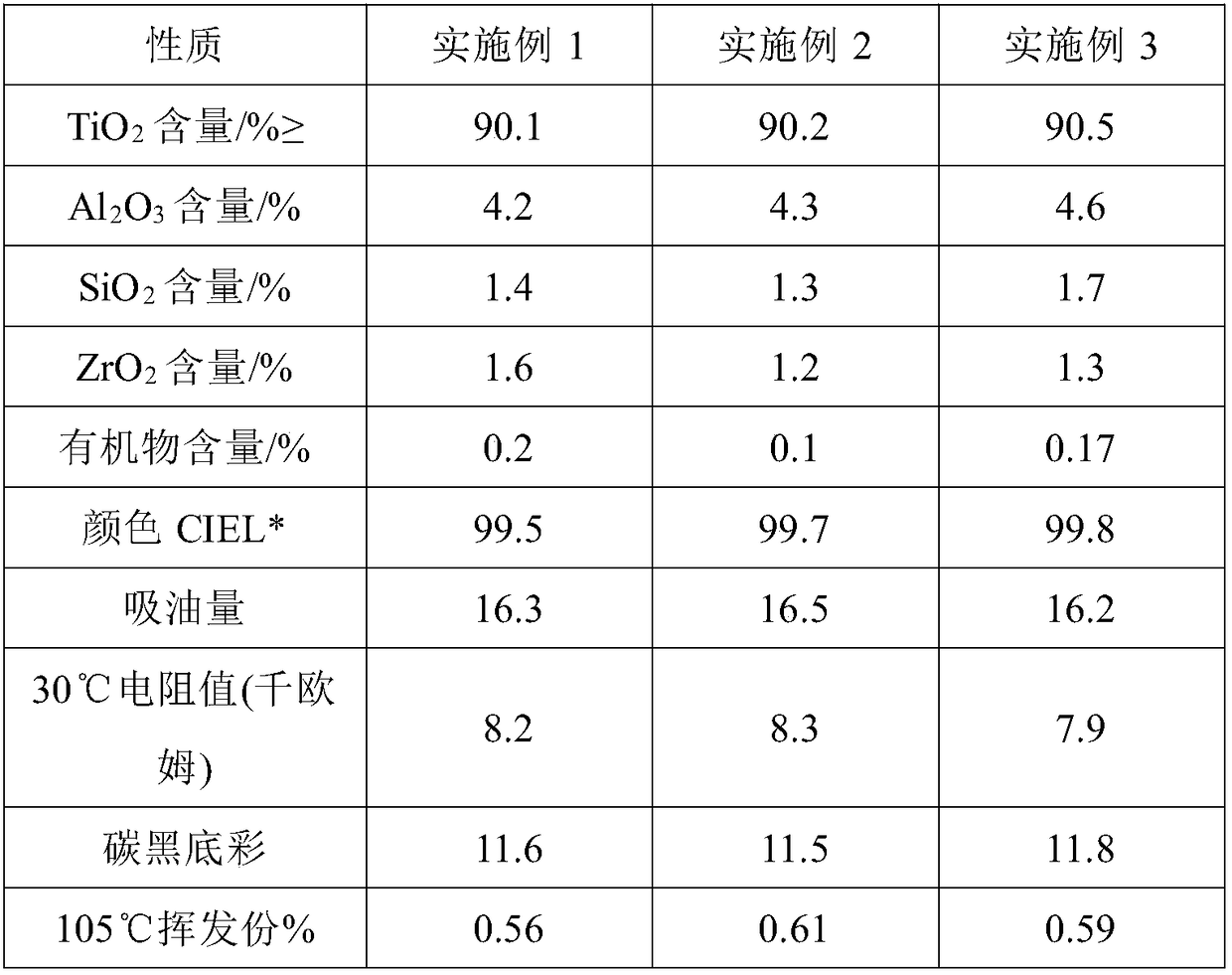

Examples

Embodiment 1

[0027] (1), the crude hydrochloric acid is diluted with pure water to a mass concentration of 5% to 10%, for subsequent use;

[0028] (2), to the titanium dioxide suspension that concentration is 10wt%, add the sodium hexametaphosphate of 0.02% of titanium dioxide powder mass, adjust pH to 8 with sodium hydroxide, stir again 2h, obtain titanium dioxide slurry;

[0029] (3), add hydrochloric acid to the titanium dioxide slurry obtained in step (2) to adjust the pH to 9, heat up to 60°C, then slowly add zirconium sulfate, the addition of zirconium sulfate accounts for 0.5% of the mass of the titanium dioxide powder, and then ripen for 30min , adjust the pH to 7 with hydrochloric acid again, and then ripen for 50 minutes;

[0030] (4), in the mixed powder slurry obtained in step (3), heat up to 70°C, add sodium silicate (using SiO 2 Calculated) is 0.5% of the mass of the titanium dioxide powder to obtain a mixed slurry, adjust the pH value to 7.5 with hydrochloric acid, and let ...

Embodiment 2

[0036](1), the crude hydrochloric acid is diluted with pure water to a mass concentration of 5% to 10%, for subsequent use;

[0037] (2), to the titanium dioxide suspension that concentration is 20wt%, add the sodium hexametaphosphate of 0.2% of titanium dioxide powder mass, adjust pH to 10 with sodium hydroxide, stir again 3h, obtain titanium dioxide slurry;

[0038] (3), in the titanium dioxide slurry obtained in step (2), heat up to 80°C, add hydrochloric acid to adjust the pH to 8, then slowly add zirconium oxychloride, the addition of zirconium oxychloride accounts for 1 / 2 of the mass of titanium dioxide powder 1%, then ripen for 60 minutes, adjust the pH to 8 with hydrochloric acid again, and then ripen for 60 minutes;

[0039] (4), lower the temperature of the mixed slurry obtained in the above step (3) to 70°C, add sodium metasilicate (using SiO 2 Calculate) is 3% of the titanium dioxide powder mass, adjust the pH value to 8.2 with hydrochloric acid, let the slurry st...

Embodiment 3

[0045] (1), the crude hydrochloric acid is diluted with pure water to a mass concentration of 5% to 10%, for subsequent use;

[0046] (2), to the titanium dioxide suspension that concentration is 30wt%, add the sodium hexametaphosphate of 0.3% of titanium dioxide powder mass, adjust pH to 12 with sodium hydroxide, stir again 4h, obtain titanium dioxide slurry;

[0047] (3) In the titanium dioxide slurry obtained in step (2), heat up to 85°C, add hydrochloric acid to adjust the pH to 9, then slowly add zirconium chloride, the addition of zirconium chloride accounts for 2% of the mass of the titanium dioxide powder , then ripen for 30-100 minutes, adjust the pH to 9 with hydrochloric acid again, and then ripen for 90 minutes;

[0048] (4), in the mixed slurry obtained in the above step (3), the temperature is lowered to 70°C, and the addition amount of sodium silicate (based on SiO 2 Calculated) is 2% of the mass of the titanium dioxide powder, the pH value is adjusted to 8.6 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com