Passivation solution for magnesium alloys and preparation method thereof

A technology of passivation solution and magnesium alloy, which is applied in the field of metallurgy to achieve the effect of solving pollution problems, excellent corrosion resistance, and fast film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

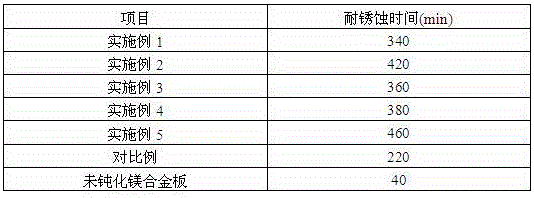

Examples

Embodiment 1

[0015] A passivation solution for magnesium alloys, the passivation solution components are: sodium molybdate 2g / L, ammonium vanadate 0.5g / L, sodium silicate 3g / L, cobalt nitrate 0.2g / L, diphosphate Manganese hydrogen 5g / L, zinc oxide 5g / L, oxalic acid 2g / L, citric acid 0.2g / L, potassium chlorate 2g / L, potassium peroxide 1g / L, ammonium fluoride 12g / L, and the balance is deionized water.

[0016] The preparation method of the passivation solution for magnesium alloys comprises the following steps: (1) take deionized water to dilute oxalic acid and citric acid, then add zinc oxide, and stir while adding to make it all dissolve; (2) Add sodium molybdate, ammonium vanadate, sodium silicate, cobalt nitrate, manganese dihydrogen phosphate, potassium chlorate, potassium peroxide, ammonium fluoride and deionized water in sequence, and stir for 15 minutes; (3) then adjust the pH with hydrofluoric acid solution value to 2.

Embodiment 2

[0018] A passivation solution for magnesium alloys, the passivation solution components are: sodium molybdate 8g / L, ammonium vanadate 2.5g / L, sodium silicate 10g / L, cobalt nitrate 2g / L, dihydrogen phosphate Manganese 12g / L, zinc oxide 15g / L, oxalic acid 5g / L, citric acid 1g / L, potassium chlorate 6g / L, potassium peroxide 3g / L, ammonium fluoride 20g / L, and the balance is deionized water.

[0019] The preparation method of the passivation solution for magnesium alloys comprises the following steps: (1) take deionized water to dilute oxalic acid and citric acid, then add zinc oxide, and stir while adding to make it all dissolve; (2) Add sodium molybdate, ammonium vanadate, sodium silicate, cobalt nitrate, manganese dihydrogen phosphate, potassium chlorate, potassium peroxide, ammonium fluoride and deionized water in sequence, and stir for 30 minutes; (3) then adjust the pH with hydrofluoric acid solution value to 4.

Embodiment 3

[0021] A passivation solution for magnesium alloys, the passivation solution components are: sodium molybdate 4g / L, ammonium vanadate 1g / L, sodium silicate 5g / L, cobalt nitrate 0.5g / L, dihydrogen phosphate Manganese 7g / L, zinc oxide 8g / L, oxalic acid 2.5g / L, citric acid 0.4g / L, potassium chlorate 2.5g / L, potassium peroxide 1.5g / L, ammonium fluoride 15g / L, and the balance is deionized water.

[0022] The preparation method of the passivation solution for magnesium alloys comprises the following steps: (1) take deionized water to dilute oxalic acid and citric acid, then add zinc oxide, and stir while adding to make it all dissolve; (2) Add sodium molybdate, ammonium vanadate, sodium silicate, cobalt nitrate, manganese dihydrogen phosphate, potassium chlorate, potassium peroxide, ammonium fluoride and deionized water in sequence, and stir for 20 minutes; (3) then adjust the pH with hydrofluoric acid solution value to 2.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com