A kind of sulfur-based cathode composite material and preparation method thereof

A composite material and positive electrode technology, which is applied in the field of sulfur-based positive electrode composite material and its preparation, can solve the problems that the sulfur content is difficult to meet the industrialization requirements, affects the industrialization process of lithium-sulfur batteries, and easily causes lithium crystal dendrites, etc., so as to suppress the shuttle effect and improve the Electrochemical performance, effect of preventing aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

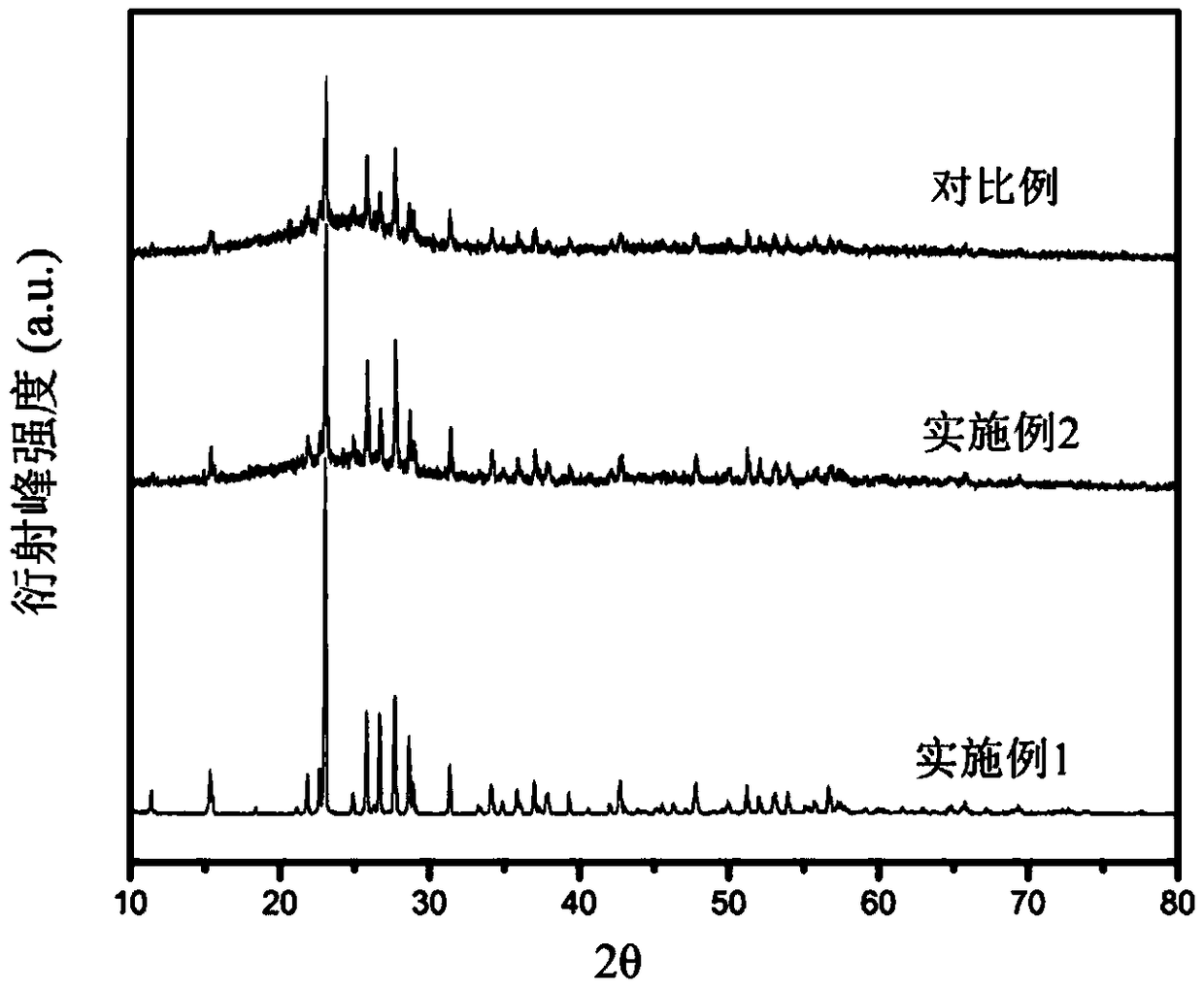

Embodiment 1

[0029] Preparation of PAN / MCM-41 composite material: select the particle size range of small-pore molecular sieve MCM-41 to be 10nm-100nm, which is beneficial to control the particle size of elemental sulfur in the nanometer range during the subsequent synthesis of elemental sulfur , to prevent the accumulation of elemental sulfur. Weigh MCM-41 and aniline according to the mass ratio of 12:1 (weigh 2g of MCM-41) and place it on an ultrasonic disperser for 2 hours, then let it stand for 6 hours, add 5ml of 1.4mol / L hydrochloric acid solution and place it under nitrogen Under the atmosphere, exhaust the tail gas into the aqueous solution of sodium hydroxide, stir mechanically for 2h, add 2ml of 0.8mol / L ammonium persulfate dropwise, transfer to the water bath and heat to 16°C, continue stirring for 20h, turn off the stirring, and let stand for 2h Finally, the conductive polymer PAN / MCM-41 composite material mixed solution is obtained.

[0030] Preparation of S-PAN / MCM-41 sulfur-l...

Embodiment 2

[0033] Preparation of PPy / MCM-41 composite material: select mesoporous molecular sieve MCM-41 with a particle size range of 10nm-100nm, disperse 2g molecular sieve MCM-41 in an aqueous solution dissolved with 5g sodium lignin, inject 0.17g new After steaming pyrrole, place it on an ultrasonic disperser for 2 hours, then let it stand for 6 hours, add 2 mL of ferric chloride solution with a concentration of 0.5 mol / L and place it under a nitrogen atmosphere, discharge the tail gas into an aqueous solution of sodium hydroxide, and place it in an ice-water bath Turn on mechanical stirring for 20 hours, turn off the stirring, and stand still for 2 hours to obtain a mixed solution of conductive polymer PPy / MCM-41 composite material supported by molecular sieves.

[0034] The preparation method of the S-PPy / MCM-41 sulfur-loaded composite material is the same as the preparation method of the sulfur-loaded composite material S-PAN / MCM-41 in Example 1 above.

[0035] (S-PPy / MCM-41) Prep...

Embodiment 3

[0037] (S-PAN / MCM-41)TiO 2 Preparation of sulfur-based composite material: According to the synthetic sulfur-loaded material S-PAN / MCM-41 in Example 1, after filtering and drying, weigh the sulfur-loaded material S-PAN / MCM-41:TiO 2 The mass ratio of 6:1 was added to the ball mill, under an inert atmosphere, the rotating speed of the ball mill was 1000 rpm, the ball milling time was 4 hours, and then the obtained product was dried at 5C for 6h, cooled and sieved to obtain a titanium dioxide package. Coated sulfur-based cathode material (S-PAN / MCM-41) TiO 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com