Purification method and preparation method for carbonyl fluoride

A purification method and carbonyl fluoride technology, which are applied in the purification method and preparation field of carbonyl fluoride, can solve the problems of exposure, high toxicity, difficulty in purification and separation, etc., and achieve the effect of reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

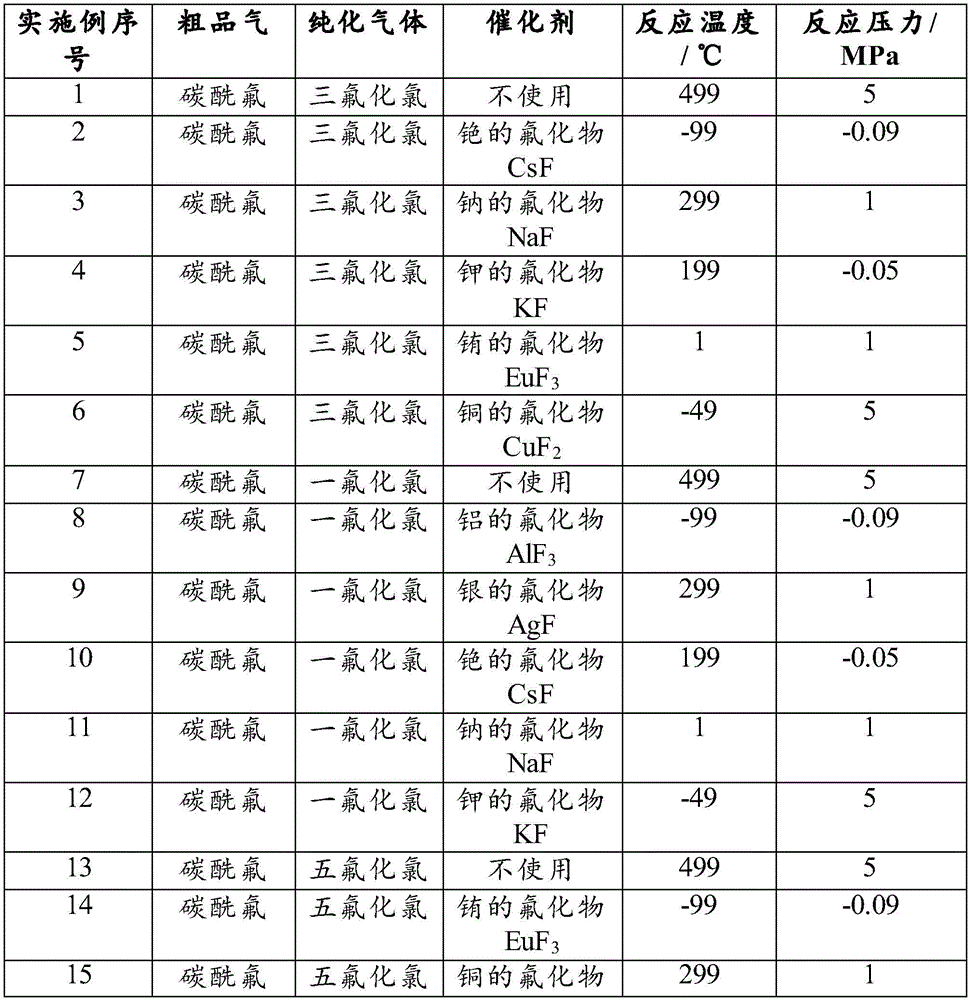

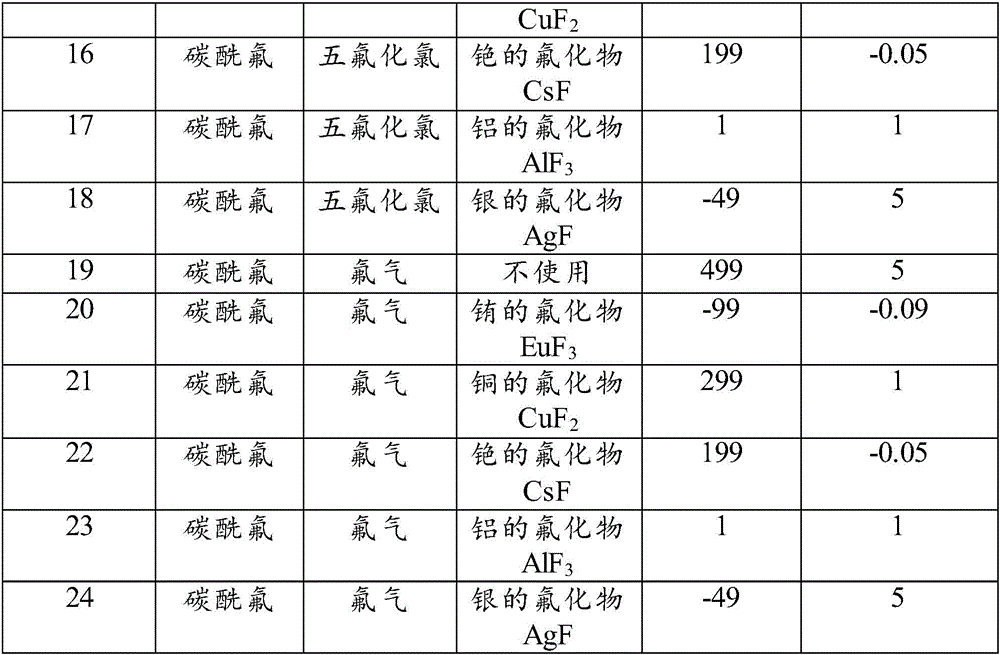

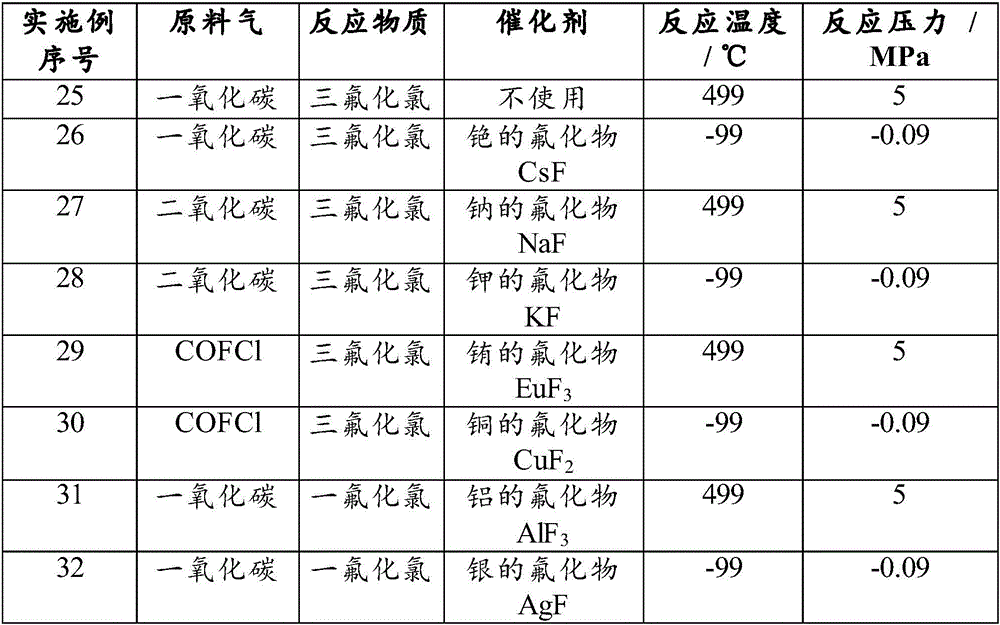

Examples

preparation example Construction

[0042] The present invention also provides a method for preparing carbonyl fluoride, comprising:

[0043] Using CO, CO 2 Any one or more of them react with fluorine-containing gas to prepare carbonyl fluoride; the fluorine-containing gas is ClF, ClF 3 and ClF 5 any one or more of

[0044] Or use COFCl to react with fluorine-containing gas to prepare carbonyl fluoride; the fluorine-containing gas is ClF, ClF 3 , ClF 5 and F 2 any one or more of them.

[0045] The present invention adopts CO, CO 2 And any one or more of COFCl, and ClF, ClF 3 , ClF 5 and F 2 Any one or more of them are raw materials, and the preparation of carbonyl fluoride gas has a higher yield and purity. At the same time, it has higher safety and economic benefits.

[0046] The present invention for the CO, CO 2 and COFCl are not particularly limited, and can be conventional CO, CO in the art 2 and COFCl.

[0047] The present invention is to described ClF, ClF 3 , ClF 5 and F 2 There is no sp...

Embodiment 1

[0061] 5 mol COF 2 The crude product gas is fed into a dry 5L stainless steel reactor device, and then fed into chlorine trifluoride for reaction, ClF 3 The molar ratio of carbonyl fluoride crude product gas is 1:1. The reaction temperature is 499°C, and the reaction pressure is 5MPa; the reaction product is derived from the gas outlet of the reactor device, passed into a cryogenic cold trap with a temperature of -110°C, and impurities are removed by freezing and vacuuming, and the purified product is collected. The gas is sent to the carbonyl fluoride refined gas storage tank, and the purified gas is detected.

[0062] Specifically, the purified gas was introduced into gas chromatography / mass spectrometer GC-MS (model GC-2014 of Shimadzu Corporation of Japan) and Fourier transform infrared spectroscopy FT-IR instrument (model Nicolet 6700) to analyze its composition. The collected gas was determined to be carbonyl fluoride by GC-MS and FT-IR, and the purity of the main comp...

Embodiment 2

[0066] The reaction temperature in the reactor is -99°C, and the reaction pressure is -0.09MPa. During the reaction, 2 grams of cesium fluoride CsF, ClF 3 The molar ratio to the carbonyl fluoride crude product gas is 1000:1 and the rest are the same as in Example 1.

[0067] The detection conditions of Example 1 are used to detect the purified gas, as can be seen: the purified gas is carbonyl fluoride with a purity of 99.95%; the impurity CO 2 Content-6 (volume ratio), COCl 2 Content-6 (volume ratio), CO content -6 (volume ratio), N 2 O content -6 (Volume ratio).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com