A 3D porous scaffold prepared using pickering high internal phase emulsion as a template

A high-internal phase emulsion and porous scaffold technology, applied in the field of 3D porous scaffold materials, can solve the problems of unfavorable biomedical materials application, large dosage, cytotoxicity, etc., and achieve low toxicity risk, high porosity, and good hydrophilicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 1.25g B-type gelatin and fully dissolve it in 25mL distilled water, then add 25mL desolvating reagent acetone, remove the supernatant, redissolve the white precipitate in 25mL distilled water and adjust its pH value to 12.0, add acetone dropwise until white A precipitate was formed, and then 250 μL of glutaraldehyde solution (25% aqueous solution) was added for cross-linking reaction for 3 hours. Finally, a centrifuge was used to centrifuge the reacted mixed solution at 10000 g for 35 minutes, redissolve the solid in the lower layer of centrifugation in water and slowly evaporate the residual acetone.

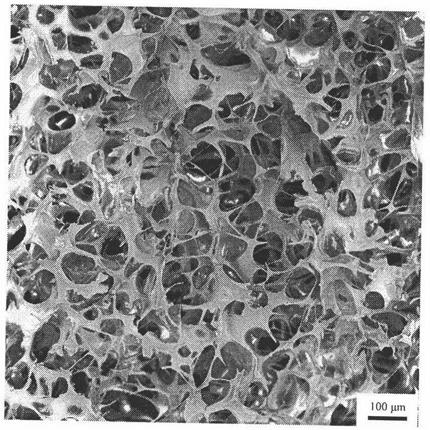

[0024] Prepare 3 mL of continuous phase aqueous solution, wherein the concentrations of Pickering stabilizer gelatin nanoparticles, functional monomer acrylamide, initiator ammonium persulfate and crosslinking agent N, N'-methylenebisacrylamide are 5 mg / mL, 2.5mol / L, 3.18mg / mL, 1.77mg / mL. Take 12mL of n-hexane as the dispersed phase, form the high internal phase em...

Embodiment 2

[0026]Take 2.5g of B-type gelatin and fully dissolve it in 50mL of distilled water, then add 50mL of desolvating reagent acetone, remove the supernatant, redissolve the white precipitate in 50mL of distilled water and adjust its pH value to 12.0, add dropwise acetone until white A precipitate was formed, and then 500 μL of glutaraldehyde solution (25% aqueous solution) was added for cross-linking reaction for 6 hours. Finally, a centrifuge was used to centrifuge the reacted mixed solution at 10000 g for 35 minutes, redissolve the solid in the lower layer of centrifugation in water and slowly evaporate the residual acetone.

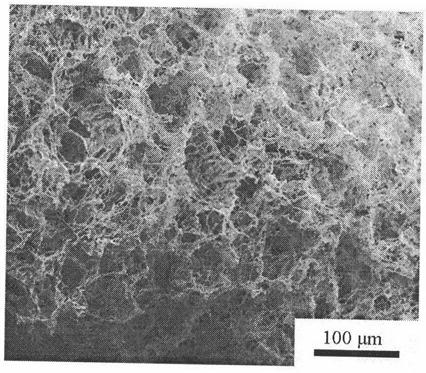

[0027] Prepare 3 mL of continuous phase aqueous solution, wherein the concentrations of Pickering stabilizer gelatin nanoparticles, functional monomer acrylamide, initiator potassium persulfate and crosslinking agent N, N'-methylenebisacrylamide are 5 mg / mL, 2.5mol / L, 3.18mg / mL, 1.77mg / mL. Take 12mL of toluene as the dispersed phase, form the high interna...

Embodiment 3

[0029] Take 1.25g B-type gelatin and fully dissolve it in 25mL distilled water, then add 25mL desolvating reagent acetone, remove the supernatant, redissolve the white precipitate in 25mL distilled water and adjust its pH value to 12.0, add acetone dropwise until white A precipitate was formed, and then 250 μL of glutaraldehyde solution (25% aqueous solution) was added for cross-linking reaction for 14 hours. Finally, a centrifuge was used to centrifuge the reacted mixed solution at 10000 g for 35 minutes, redissolve the solid in the lower layer of centrifugation in water and slowly evaporate the residual acetone.

[0030] Prepare 3mL continuous phase aqueous solution, wherein the concentrations of Pickering stabilizer gelatin nanoparticles, functional monomer hydroxyethyl acrylate, initiator ammonium persulfate and crosslinking agent N, N′-methylenebisacrylamide are 10 mg / mL, 5.0mol / L, 2.9mg / mL, 11.6mg / mL. Take 12mL p-xylene as the dispersed phase, form the high internal ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com