Heat insulation film and heat insulation material

A technology of thermal insulation material and thermal insulation film, applied in synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of high cost, decline of infrared blocking rate, complicated manufacturing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

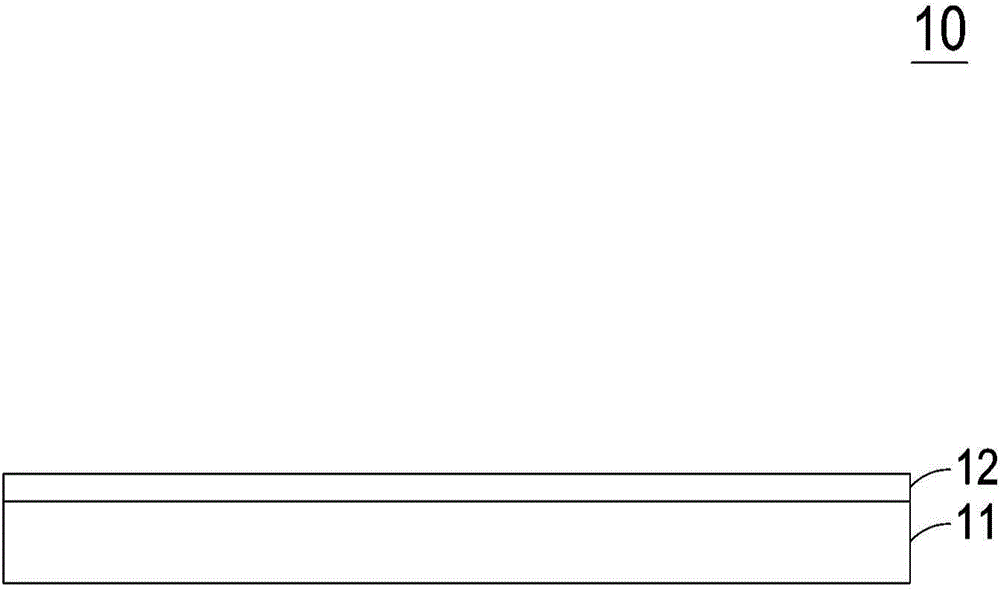

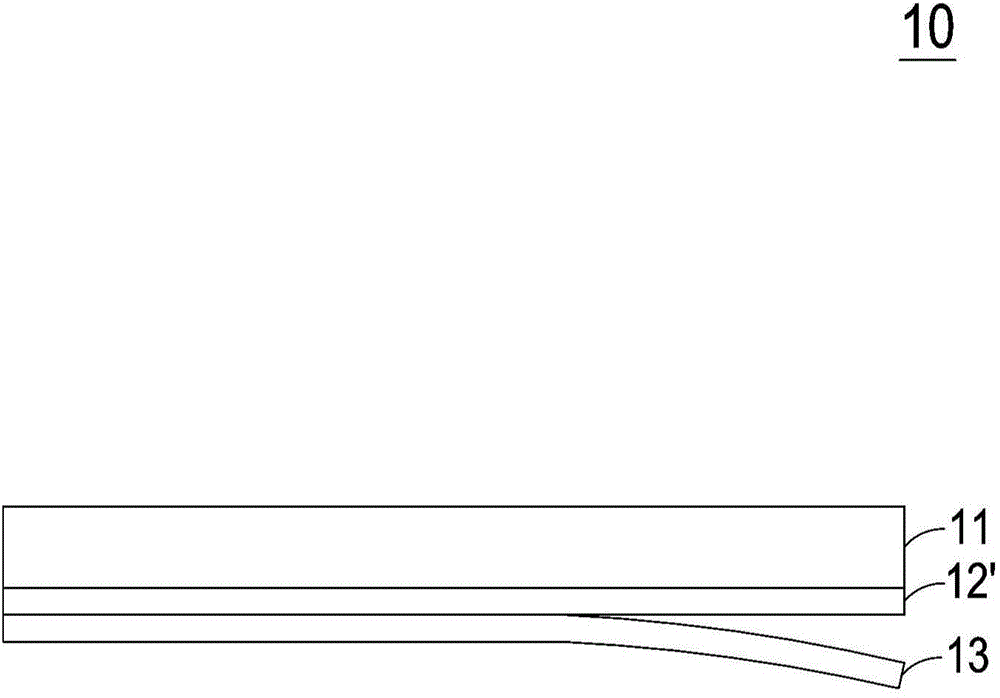

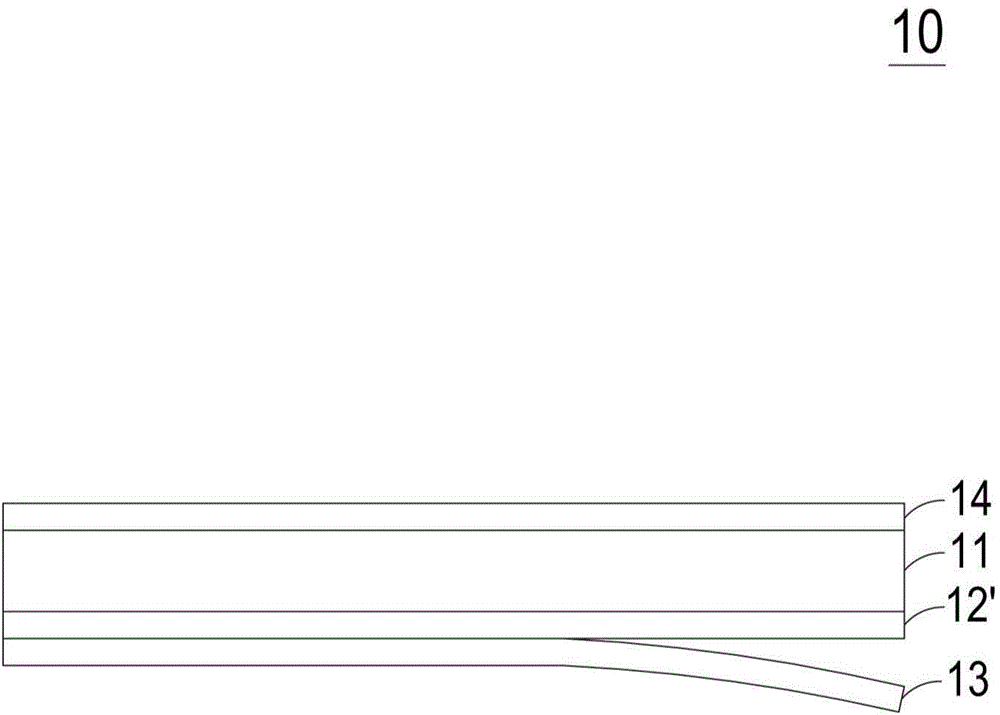

Method used

Image

Examples

Embodiment 1

[0098] Mix an appropriate amount of tungstic acid and hydrogen peroxide uniformly at an appropriate temperature of 30-50°C to form a melt, then use a platinum catalyst net to catalyze and decompose the residual hydrogen peroxide into oxygen and water for removal, and obtain solution A . Then tetrabutylammonium hydroxide was added to the ethanol solution and mixed to prepare 25% tetramethylammonium hydroxide-ethanol solution B. Solution A and solution B were co-precipitated to form a precipitate, and then the precipitate was aged for 12 hours, then heated and dried at 60°C to obtain carbon-doped WO 3 Prebody. Then, under the hydrogen atmosphere at 500°C, sintering at a heating rate of 2°C per minute for 1 hour, after the heat treatment is completed, a monoclinic composite tungsten oxycarbide powder is obtained, in which the doping amount of carbon is 0.82 atoms percentage.

[0099] Afterwards, after grinding the composite tungsten oxycarbide powder into a fine powder, add a ...

Embodiment 2

[0102] Dissolve 5.3g of tungsten hexachloride in 500ml of ethanol to make solution A, and mix 0.5g of cesium chloride with 100ml of ethanol to make solution B, then mix solution A and solution B to make solution C. Use 248nm KrF excimer laser on solution C to give pulse irradiation for 30 minutes at a fixed frequency of 8HZ and energy of 10mJ to obtain a composite tungsten oxycarbon chloride precursor, and then place the precursor in a hydrogen atmosphere at 500°C, with a heating rate of After sintering for 1 hour at 2°C for 1 minute, a composite tungsten oxycarbon chloride powder is obtained after the heat treatment is completed, wherein the doping amount of carbon is 0.63 atomic percent.

[0103] Afterwards, after grinding the composite tungsten oxycarbon chloride powder into a fine powder, it was added into a methyl ethyl ketone solvent to prepare a solution with a weight ratio of 27%, and a polymer dispersant with a weight ratio of 10% was added, using 100 μm yttrium oxide ...

Embodiment 3

[0106] This example is roughly the same as Example 1, except that the solution B is a 30% tetramethylammonium hydroxide-ethanol solution prepared by adding tetrabutylammonium hydroxide to an ethanol solution and mixing. The composite tungsten oxycarbide powder prepared in this example was tested, and it was found that the doping amount of carbon was 0.91 atomic percent. Further, the visible light transmittance (VLT%) and the infrared rejection rate (IR rejection%) of the transparent heat-insulating film with a wavelength of 300 to 2500 nm were measured, and the measurement results showed that VLT%=70%, and the IR rejection rate%=83% , 1000hr QUV test IR blocking rate% = 80%, so the IR blocking rate declines by about 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com