Sewage acid treatment method and system

A treatment method and technology for polluted acid, applied in the field of chemical technology, can solve the problems of only focusing on the treatment of polluted acid heavy metals and arsenic, increasing maintenance costs, equipment and pipeline corrosion, etc., achieving simple structure, increasing gas-liquid contact area, reducing The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A treatment method for polluted acid, comprising the following steps:

[0043] (1) Take polluted acid wastewater, and detect that the mass fraction of sulfuric acid in the wastewater is 10%, the concentration of chloride ions is 2000mg / L, and the concentration of fluoride ions is 2000mg / L.

[0044] (2) Filter the polluted acid through a fiber bundle (pore size 50 μm) made of polypropylene (pp) to obtain a supernatant.

[0045] (3) Take part of the low-temperature flue gas (temperature is about 115°C, similar to air) in the electrolysis stage of non-ferrous metal smelting and exchange heat with the supernatant in the heat exchanger (the low-temperature flue gas and the supernatant do not contact each other), The supernatant was prewarmed to 60°C.

[0046] (4) The preheated low-temperature flue gas is dried in a gas drying tower until the water content is less than 20mg / Nm 3 . The temperature of the dried low-temperature flue gas is about 105° C.; under this temperature ...

Embodiment 2

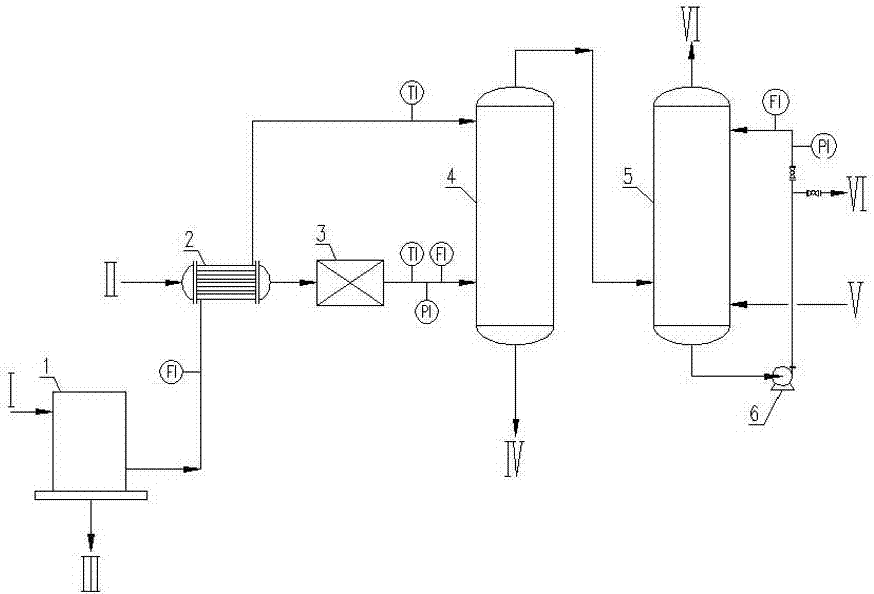

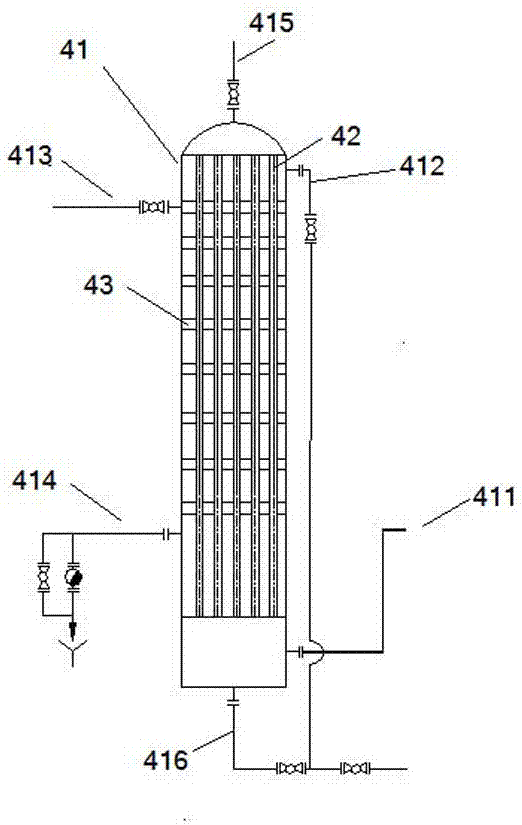

[0050] see figure 1 and figure 2 , a dirty acid wastewater treatment system of the present invention, comprising an acid filter 1, a heat exchanger 2, a gas drying tower 3, a purging reaction tower 4 and a tail gas absorption tower 5, the liquid inlet of the heat exchanger 2 and the acid filter The device 1 is communicated, the liquid outlet is communicated with the liquid inlet 412 of the purging reaction tower 4, the gas outlet of the heat exchanger 2 is communicated with the air inlet 411 of the purging reaction tower 4 through the gas drying tower 3, and the purging reaction tower 4 The air inlet 411 is located below the liquid inlet 412 of the purging reaction tower 4, and the gas outlet 415 of the purging reaction tower 4 communicates with the tail gas absorption tower 5. Wherein the gas flow pipelines of heat exchanger 2, gas drying tower 3, purge reaction tower 4, and tail gas absorption tower 5 are connected in sequence to form gas flow channels; the liquid flow pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com