Disinfection laundry detergent

A technology of laundry detergent and whitening agent, applied in the direction of detergent compounding agent, detergent composition, organic washing composition, etc., can solve the problems of poor water solubility, no obvious effect of Candida albicans, and difficult degradation, etc., to achieve Good sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

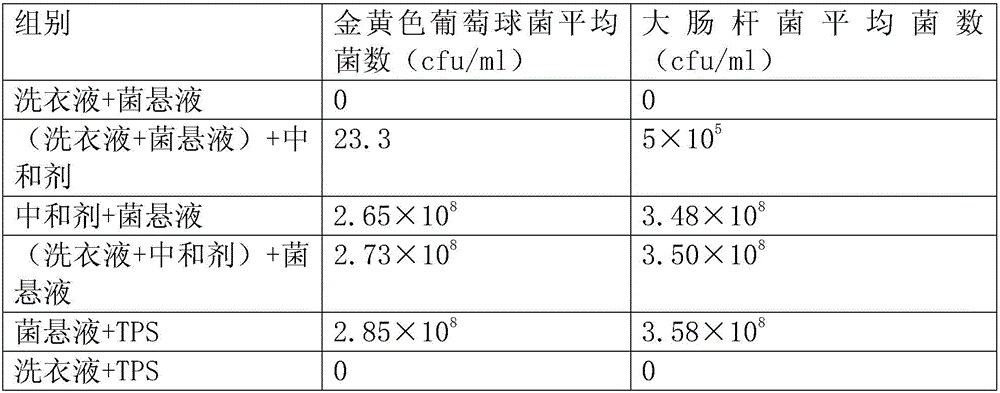

Method used

Image

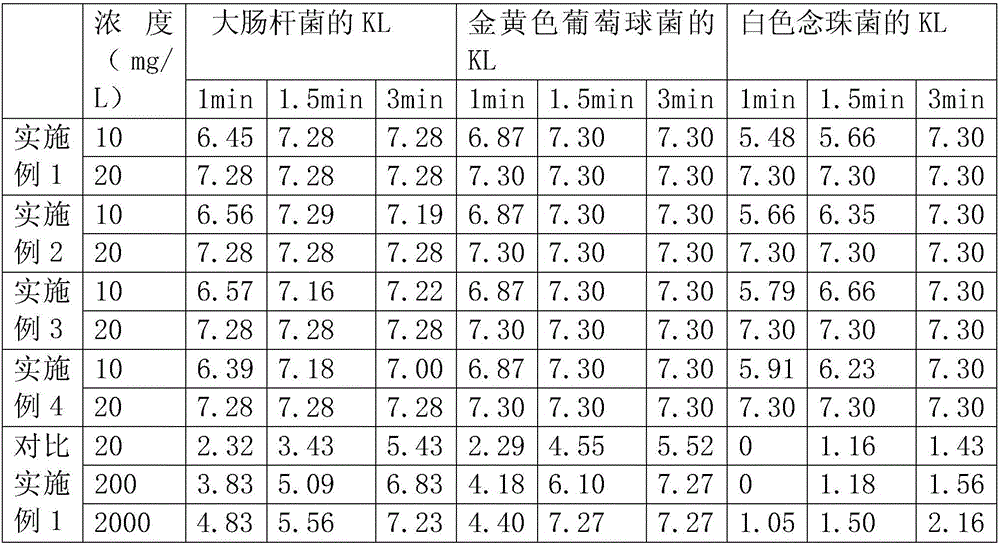

Examples

Embodiment 1

[0016] Dodecyl dimethyl benzyl ammonium bromide 10kg, dioctadecyl dimethyl ammonium chloride 5kg, ethylene oleic acid amide ethylenediamine hydrochloride 5kg, fatty alcohol polyoxyethylene ether 8kg, card Boehm 0.1kg, hydroxyethylidene diphosphonic acid 0.1kg, deionized water 80kg.

[0017] Preparation:

[0018] 1) Take 30-40% of the total amount of deionized water and add it to the stirring tank, heat it to 70-80°C, add dodecyldimethylbenzyl ammonium bromide, dioctadecyl di Methyl ammonium chloride, ethylene oleic acid amide ethylenediamine hydrochloride and fatty alcohol polyoxyethylene ether are dissolved and stirred for 0.5 to 1 hour to make them evenly mixed to obtain the surfactant stock solution;

[0019] 2) Take 30-40% of the total amount of deionized water and add it to the stirring tank, heat it to 50-60°C, add the thickener while stirring, and continue stirring until the solution is uniform and transparent to obtain the stock solution of the thickener;

[0020] 3)...

Embodiment 2

[0022] Dodecyl dimethyl benzyl ammonium bromide 15kg, dioctadecyl dimethyl ammonium chloride 10kg, ethylene oleic acid amide ethylenediamine hydrochloride 10kg, fatty alcohol polyoxyethylene ether 15kg, carboxylate Sodium methylcellulose 0.5kg, sodium citrate 0.5kg, deionized water 95kg.

[0023] The preparation method is the same as in Example 1.

Embodiment 3

[0025] Dodecyl dimethyl benzyl ammonium bromide 12kg, dioctadecyl dimethyl ammonium chloride 8kg, ethylene oleic acid amide ethylenediamine hydrochloride 8kg, fatty alcohol polyoxyethylene ether 12kg, yellow Raw gum 0.3kg, hydroxyethylidene diphosphonic acid 0.3kg, sodium edetate 0.4kg, deionized water 90kg.

[0026] Preparation:

[0027] 1) Take 30-40% of the total amount of deionized water and add it to the stirring tank, heat it to 70-80°C, add dodecyldimethylbenzyl ammonium bromide, dioctadecyl di Methyl ammonium chloride, ethylene oleic acid amide ethylenediamine hydrochloride and fatty alcohol polyoxyethylene ether are dissolved and stirred for 0.5 to 1 hour to make them evenly mixed to obtain the surfactant stock solution;

[0028] 2) Take 30-40% of the total amount of deionized water and add it to the stirring tank, heat it to 50-60°C, add the thickener while stirring, and continue stirring until the solution is uniform and transparent to obtain the stock solution of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com