Puffed and fermented protein feed additive and application thereof

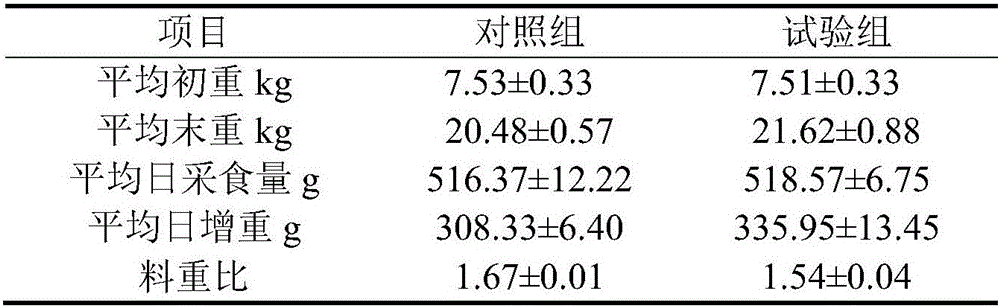

A fermented protein feed and additive technology, which is applied in the forming or processing of animal feed, application, animal feed, etc., can solve the problems of unreasonable use of feathers and animal hair, great differences in fermentation quality, and environmental pollution, etc., and achieve good results. Food-attracting effect, good palatability, effect of promoting animal growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The kind of koji preparation of embodiment 1 bacterial classification

[0028] (1) Endomycopsis fibuligera yeast (Endomycopsis fibuligera ACCC20015, purchased from China Agricultural Microorganism Culture Collection Management Center)

[0029] Test tube of Saccharomyces fumigatus yeast original bacteria - small triangular bottle seeds (maltose sugar solution 100ml, sugar content 7-8°Be) incubated at 30°C for 10h - transfer to large triangular bottle (maltose sugar solution 600ml, sugar content 7-8 °Be), culture at 30°C for 10 hours——transfer to Karst jars (sugar water 13kg, sugar content 7-8°Be to expand cultivation) 30°C for 10 hours—expand the yeast seeds in Karst jars (culture medium Put 200kg of clear water in each tank, 30kg of corn flour, and 10kg of bran) for a total culture time of 20 hours, which is the yeast seed liquid of S.

[0030] (2) Bacillus licheniformis (Bacillus licheniformis ACCC01198, purchased from China Agricultural Microorganism Culture Collecti...

Embodiment 2

[0036] Embodiment 2 puff preparation

[0037] Mix 100kg of soybean meal with 50kg of chicken feather (crushed to 20 mesh), then mix the mixture of soybean meal and chicken feather with 15kg of water, and send it to the conditioner of the extruder after mixing (YDPH 100S wet-process extruder, Hebei Yada Machinery Manufacturing Co., Ltd. Company) for steam tempering treatment, the steam tempering temperature is 85°C, and the steam addition amount is 10% (ie 15kg); the tempered material is sent into the puffing machine cavity for ring die puffing, and the puffing temperature is 110°C , pressure 5MPa, die hole ф8mm, puffing time 30s, screw speed 220r / min; the puffed material was cooled and dried so that the water mass concentration was lower than 10%, and 152kg soybean meal feather puffed product was obtained.

Embodiment 3

[0038] Embodiment 3 puff preparation

[0039] Mix 75kg of soybean meal with 150kg of duck feather (crushed to 20 mesh), and then mix the mixture of soybean meal and duck feather with 28kg of water. After mixing, send it to the conditioner of the extruder for steam conditioning treatment. The steam conditioning temperature is 90 ℃, the amount of steam added is 12.5% (28kg); the material after quenching and tempering is sent into the cavity of the extruder for ring die expansion, the expansion temperature is 120 °C, the pressure is 6.5 MPa, the die hole is ф9mm, the expansion time is 32.5s, the screw speed 235r / min; cooling and drying the puffed material so that the moisture content is lower than 10%, and 230kg of puffed soybean meal feathers are obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com