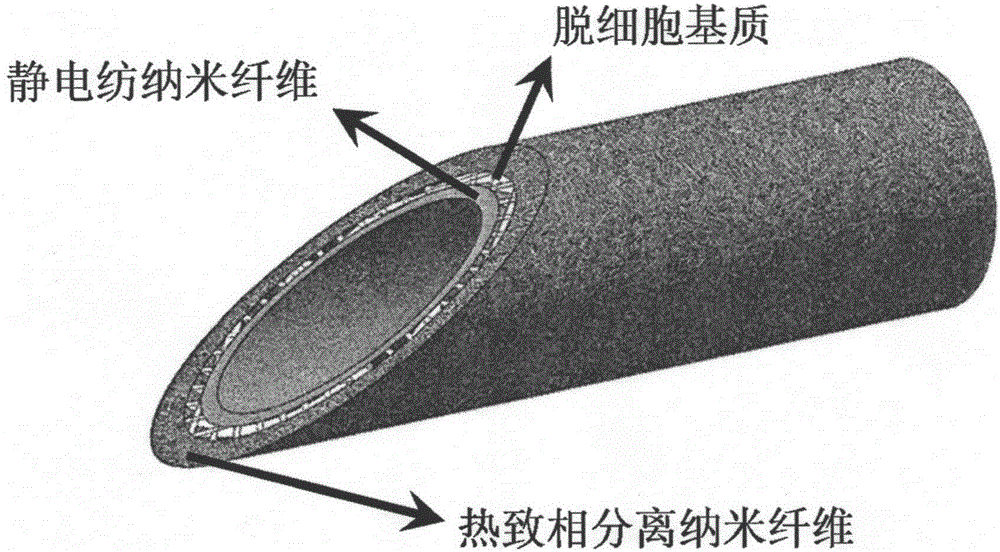

Thermally-induced phase separation nanofiber tubular stent and preparation method thereof

A thermally induced phase separation, nanofiber technology, applied in pharmaceutical formulations, medical science, prostheses, etc., can solve the problem that small-diameter tubular stents have not yet appeared, and achieve the effect of promoting rapid growth and rapid endothelialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

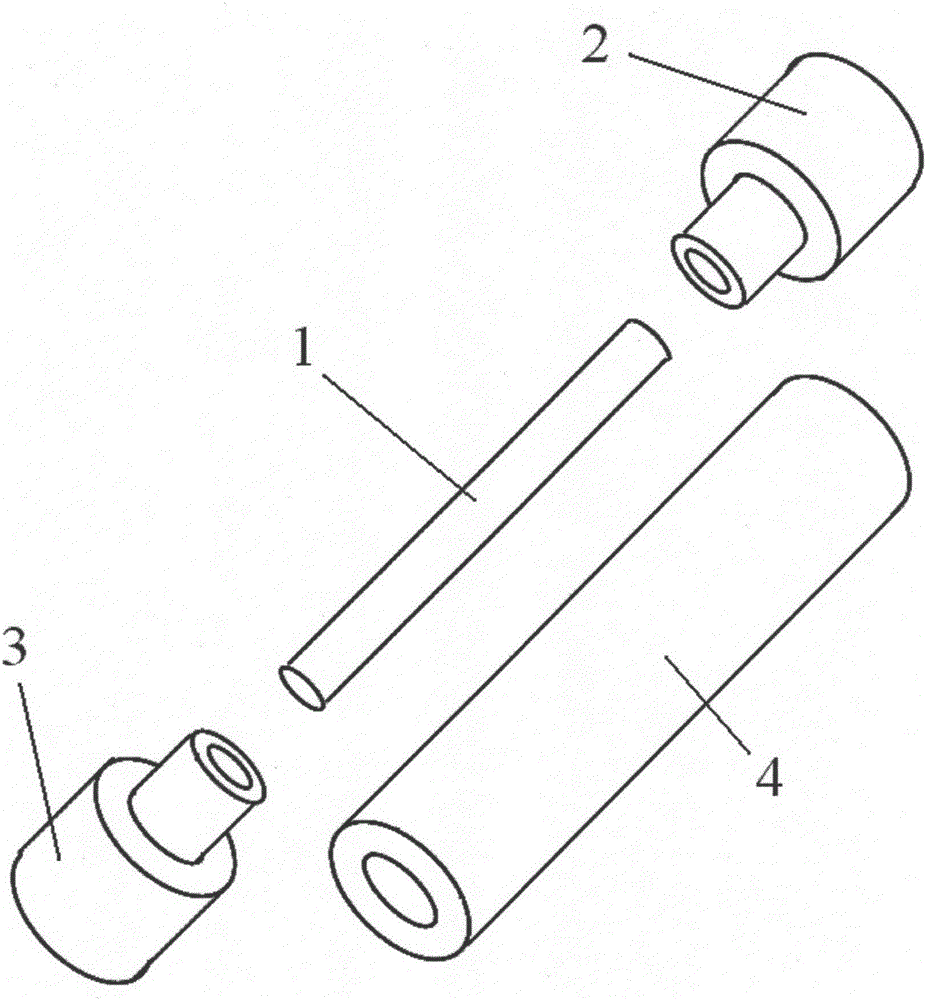

[0033] The preparation mold that embodiment 1 and embodiment 2 adopts is as figure 2 As shown, it includes a mold shaft core 1 for receiving and a mold outer sheath tube 4 sleeved on its outside. The two ends of the mold shaft core 1 are respectively provided with a mold anti-leakage plug 1 2 and a mold anti-leakage plug 2 3 .

[0034] Example 1

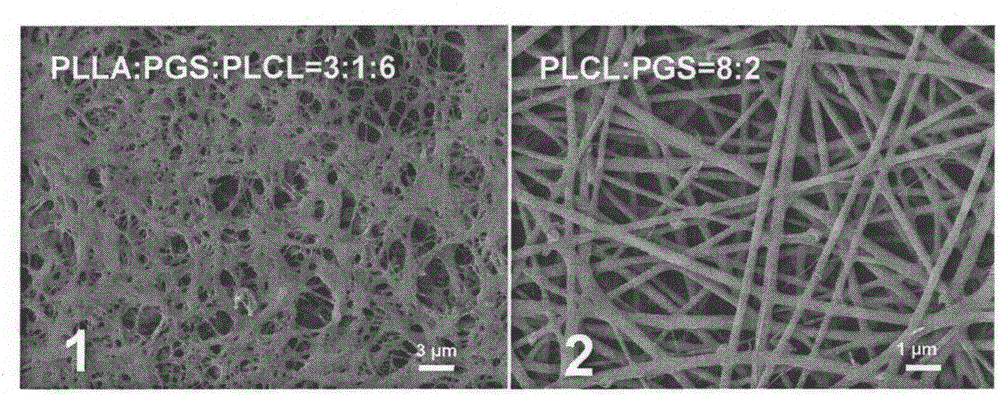

[0035] Take 8-month-old healthy porcine thoracic aorta with a caliber of about 3 mm, conduct decellularization treatment, and soak in 0.9% saline for standby; Pure water until all the substrates are submerged, put in -80°C refrigerator for 60 hours, freeze-dry for 60 hours after taking out, and refrigerate at -20°C for later use. Weigh 0.4g PLLA, 0.2gPGS and 0.4gPLCL materials on an analytical balance and mix together, add 10mL tetrahydrofuran solvent, seal the screw-top reaction bottle with a parafilm, place it in a 60°C water bath, and stir it magnetically until the mass / volume fraction is 10% clear homogeneous solution. Subseq...

Embodiment 2

[0037]Take an 8-month-old healthy SD abdominal aorta with a caliber of about 2.2mm, perform decellularization treatment, and soak it in 0.9% normal saline for later use; put the decellularized matrix obtained after treatment in a watch glass, add dropwise Ultrapure water until all the matrix is submerged, put into -80°C refrigerator for 48 hours, take it out and freeze-dry for 48 hours, and refrigerate at -20°C for later use; spin 0.1mm thick nanofibers on the inner diameter of the mold with a stainless steel shaft of 2mm, The nanofibers and the shaft core were put into a vacuum drying oven to dry; the refrigerated decellularized tubular matrix was taken out and placed on the spun nanofiber shaft core as a mechanical reinforcement layer; 0.3g PLLA, 0.1gPGS and 0.6g were weighed on an analytical balance. The g PLCL materials were mixed together, 10 mL of tetrahydrofuran solvent was added, the screw-top reaction bottle was sealed with a parafilm, placed in a 60°C water bath, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com