Environment-friendly coating for steel ring wheel

A green environmental protection, wheel technology, applied in the field of coatings, can solve problems affecting the effect of coatings, damage to the environment and human health, coating peeling, etc., and achieve the effect of improving life expectancy, good adhesion, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

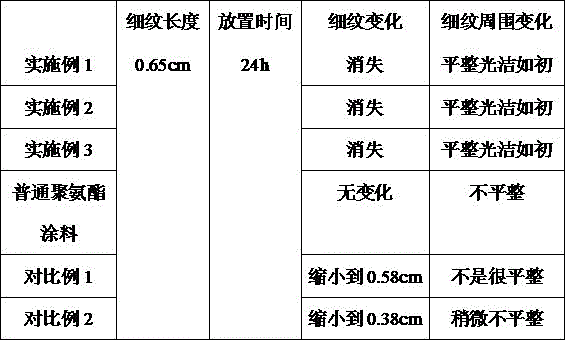

Examples

Embodiment 1

[0020] A green environmental protection coating for steel rim wheels, made of the following components in parts by weight, polyurethane emulsion 76-78, butyl acetate 4-6, vinyl silicone oil 2-4, nano titanium dioxide 1-3, attapulgite 1- 2. Mica powder 1-2, acetylcholine 2-3, water 78-80, aluminum borate whiskers 1-3, menthyl acetate 1-2, plant gum 4-6, plant extract 0.3-0.5, film-forming aid 0.6-0.8;

[0021] The polyurethane emulsion has been modified: add the polyurethane emulsion into the reaction kettle, heat it to 50°C, and keep it warm for 25 minutes, then add the mixture of sericin and hydroxymethyl chitosan with 1.5% of its mass, and then add the mixture at 300r / min Stir at high speed, and increase the temperature at a rate of 2°C / min. After 30 minutes, stop stirring and stop heating. After keeping the heat for 20 minutes, cool naturally to room temperature. Sericin and hydroxymethyl chitosan Sugar is mixed in a mass ratio of 2:3;

[0022] The film-forming aid is mad...

Embodiment 2

[0031] Polyurethane emulsion 78, butyl acetate 6, vinyl silicone oil 4, nano-titanium dioxide 3, attapulgite 2, mica powder 2, acetylcholine 3, water 80, aluminum borate whiskers 3, menthyl acetate 2, vegetable gum 6, plant extract Liquid 0.5, film-forming aid 0.8;

[0032] The polyurethane emulsion has been modified: add the polyurethane emulsion into the reaction kettle, heat it to 50°C, and keep it warm for 25 minutes, then add the mixture of sericin and hydroxymethyl chitosan with 1.5% of its mass, and then add the mixture at 300r / min Stir at high speed, and increase the temperature at a rate of 2°C / min. After 30 minutes, stop stirring and stop heating. After keeping the heat for 20 minutes, cool naturally to room temperature. Sericin and hydroxymethyl chitosan Sugar is mixed in a mass ratio of 2:3;

[0033] The film-forming aid is made of the following components in parts by weight: 6 epoxy resins, 2 modified starches, 0.5 sodium acrylamido isopropyl sulfonate, and 1 ros...

Embodiment 3

[0042] A green environmental protection coating for steel rim wheels, made of the following components in parts by weight, polyurethane emulsion 76, butyl acetate 5, vinyl silicone oil 2, nano-titanium dioxide 1, attapulgite 1, mica powder 1, acetylcholine 3, water 79. Aluminum borate whisker 2, menthyl acetate 2, vegetable gum 5, plant extract 1.4, film-forming aid 0.7;

[0043] The polyurethane emulsion has been modified: add the polyurethane emulsion into the reaction kettle, heat it to 50°C, and keep it warm for 25 minutes, then add the mixture of sericin and hydroxymethyl chitosan with 1.5% of its mass, and then add the mixture at 300r / min Stir at high speed, and increase the temperature at a rate of 2°C / min. After 30 minutes, stop stirring and stop heating. After keeping the heat for 20 minutes, cool naturally to room temperature. Sericin and hydroxymethyl chitosan Sugar is mixed in a mass ratio of 2:3;

[0044] The film-forming aid is made of the following components i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com