Fast-charging lithium ion battery, cathode material thereof and preparation method of cathode material

A technology of lithium-ion batteries and negative electrode materials, applied in the direction of battery electrodes, batteries, secondary batteries, etc., can solve the problems of high power density, high capacity density, long cycle life, high capacity, long life electronic equipment, and constraints Lithium-ion battery capacity and other issues, to achieve the effect of ultra-fast charge and discharge capacity, enhanced electrochemical performance, and good mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

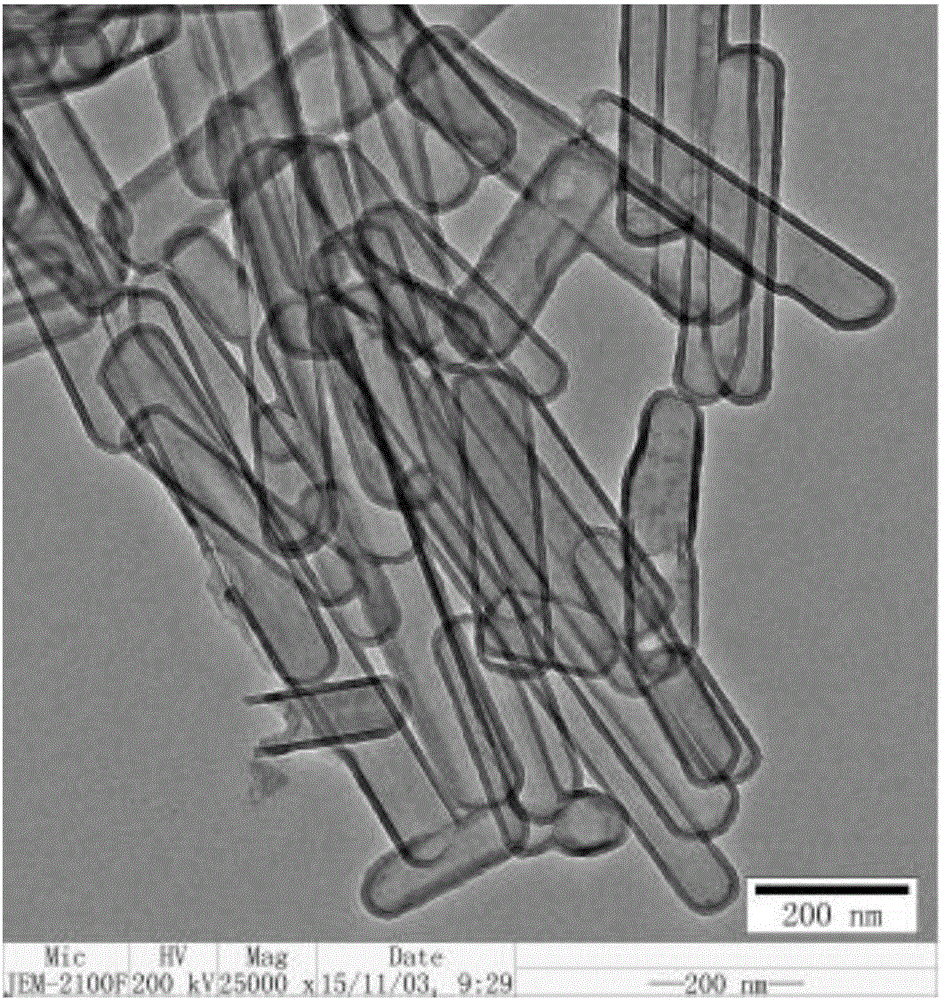

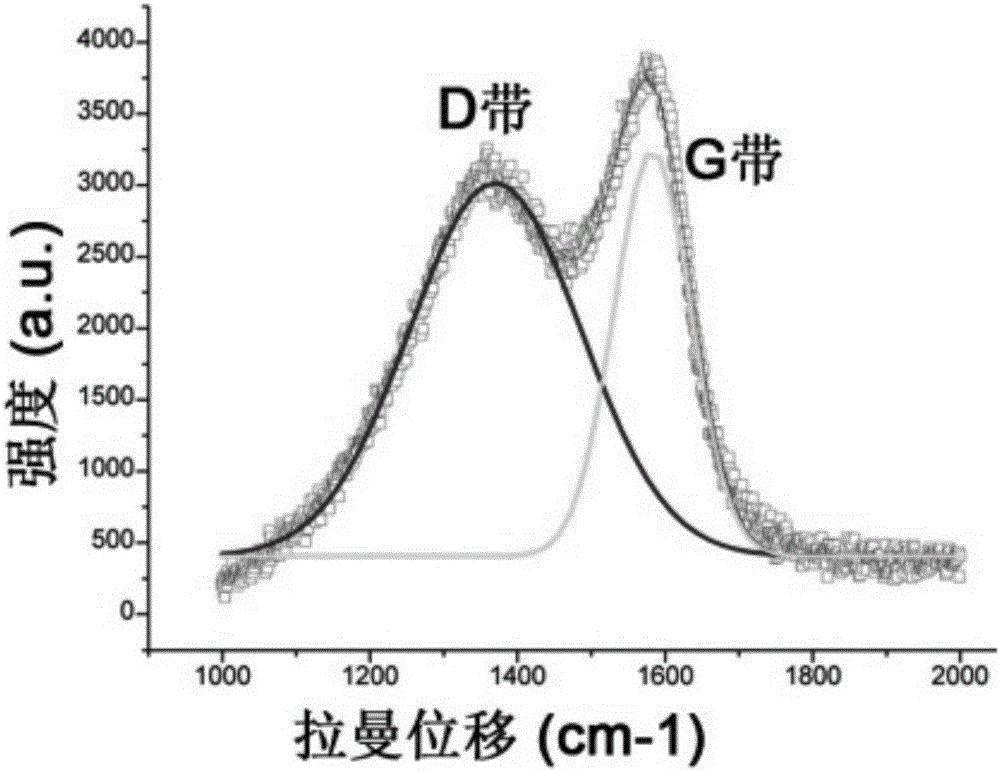

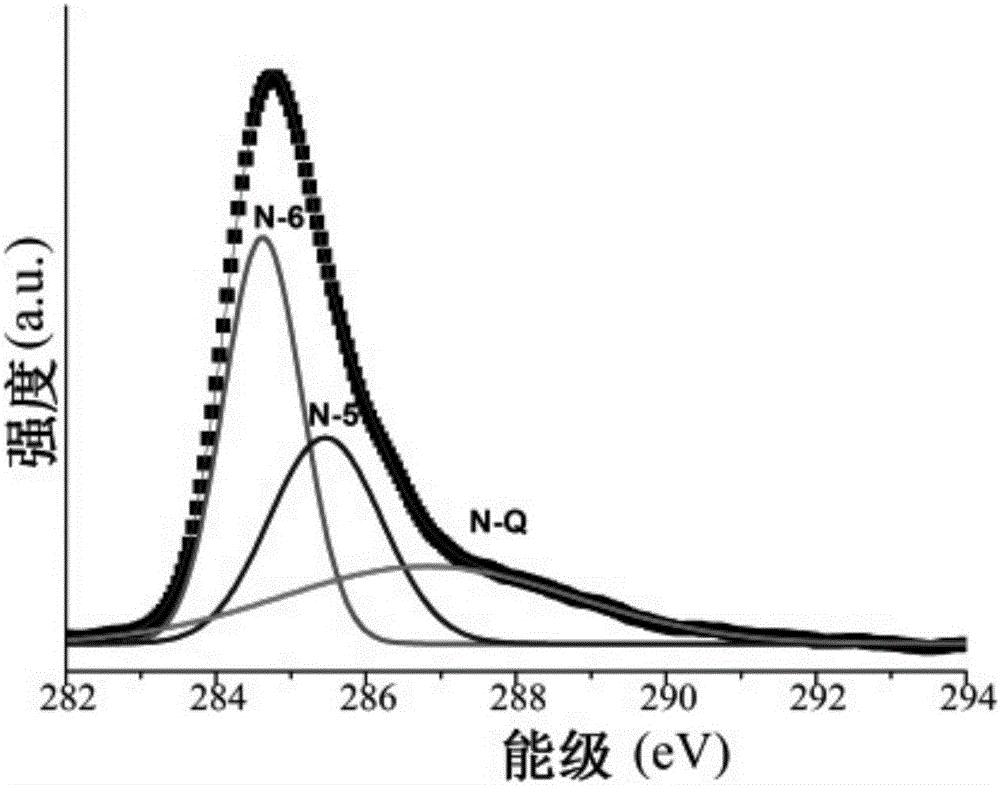

[0035] Weigh 0.15g of zinc germanate nanorod templates with an average length of 480nm and an outer diameter of 65nm, disperse them in a mixed solution of 20ml ethanol and 15ml water, weigh 0.23g of dopamine hydrochloride, add them to the above solution, and then add 0.05g tris(hydroxymethyl)aminomethane and 10ml water, stirred at room temperature for 20h. After centrifugation, cleaning, and drying, put the dried sample into a tube furnace, first pass in argon to remove the air, continue to pass in argon, then heat up to 550°C, carbonize for 4 hours, and finally cool to room temperature with the furnace After sampling, the precursor is obtained. Next, 0.2 g of the precursor was weighed and soaked in 80 mL of aqua regia, and after standing still for 1 day, it was centrifuged, washed, and dried to obtain the negative electrode material of the lithium ion battery.

[0036] The negative electrode material was tested by transmission electron microscopy, and the results were as fol...

Embodiment 2

[0040] Weigh 0.15g of the zinc germanate nanorod template with an average length of 480nm and a diameter of 65nm, and disperse it into a mixed solution of 20mL of ethanol and 15mL of water, and weigh 0.075g of dopamine hydrochloride, add it to the above solution, and then add 0.05g of tris(hydroxymethyl)aminomethane, and 10mL of water, stirred at room temperature for 20h, centrifuged, washed, and dried, put the dried sample into a tube furnace, first pass in argon to remove the air, and continue Introduce argon, then raise the temperature to 550°C, and carbonize for 4h. Finally, samples were taken after the furnace was cooled to room temperature to obtain the precursor; then 0.2 g of the precursor was weighed and soaked in 80 mL of aqua regia, and after standing for 1 day, it was centrifuged, washed and dried to obtain the negative electrode material.

[0041] The obtained lithium ion battery negative electrode material is mixed with binder vinylidene fluoride (PVDF) and condu...

Embodiment 3

[0043] Weigh 0.15g of the copper germanate nanorod template with an average length of 900nm and a diameter of 40nm, and disperse it into a mixed solution of 20mL ethanol and 15mL water, and weigh 0.23g of dopamine hydrochloride, add it to the above solution, and then add 0.05g of tris(hydroxymethyl)aminomethane, and 10mL of water, stirred at room temperature for 20h, centrifuged, washed, dried, put the dried sample into a tube furnace, first pass in argon to remove the air, continue Introduce argon, then raise the temperature to 550°C, and carbonize for 4h. Finally, samples were taken after the furnace was cooled to room temperature to obtain the precursor; then 0.2 g of the precursor was weighed and soaked in 80 mL of aqua regia, and after standing for 1 day, it was centrifuged, washed and dried to obtain the negative electrode material.

[0044] The lithium-ion battery negative electrode material obtained in this embodiment is mixed with the binder vinylidene fluoride (PVDF)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com