Ionic liquid polymer, electrolyte and lithium battery

An ionic liquid, lithium-ion battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problem of low conductivity of all-solid polymer electrolytes, and achieve good cycle performance, high ionic conductivity, and film-forming properties. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

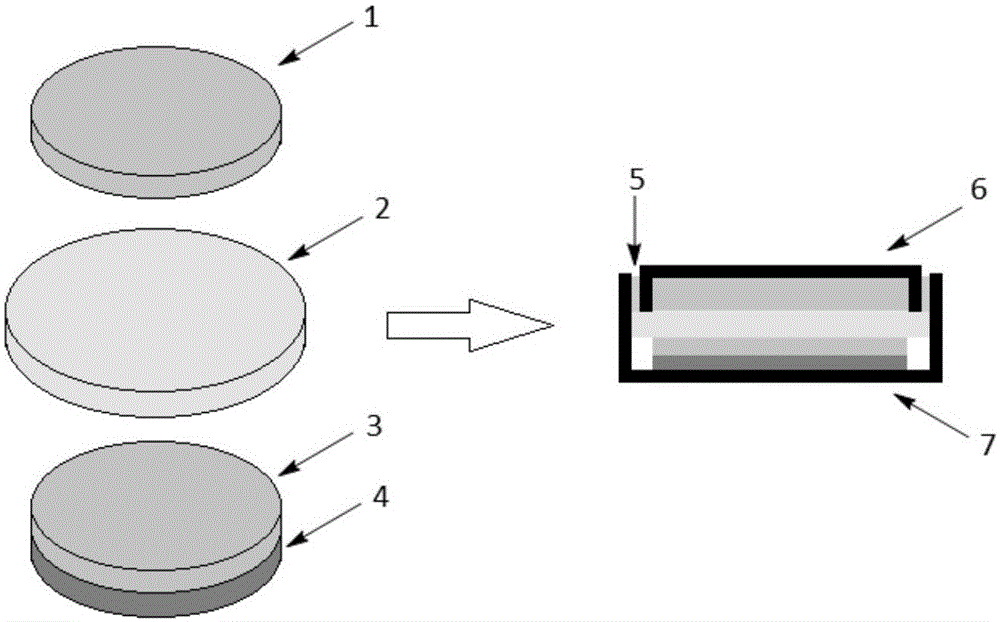

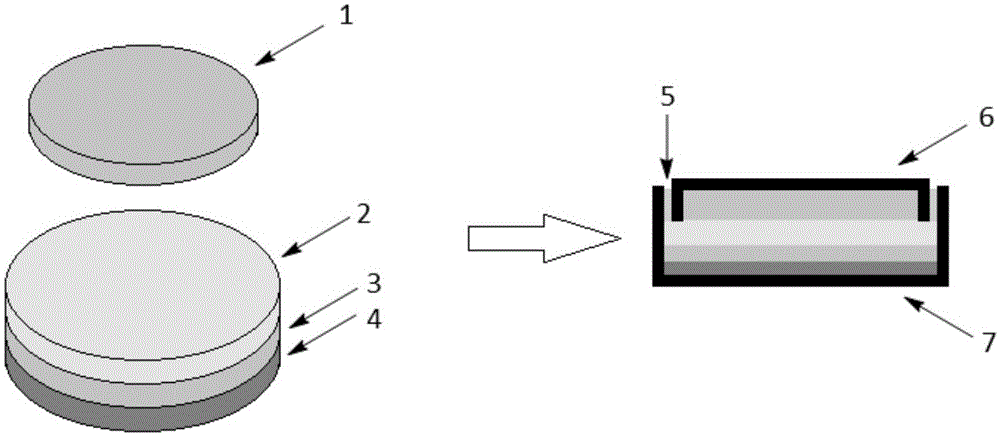

[0140] The preparation method of the electrolyte of the present invention is conventional, and those skilled in the art can directly deduce the specific method according to the description of the present invention combined with the prior art. In a preferred example of the present invention, the electrolyte can be prepared as follows:

[0141] (1) Mix one or several ionic liquids described in the present invention with one or more polymercapto compounds described in the present invention, and control alkenyl (1 mole of alkynyl is equivalent to 2 moles of alkenyl) and mercapto The molar ratio is 1:1, then add the photoinitiator of 0.1%-5.0% (preferably 0.1-2.0% by weight) by weight, and stir until the solid is completely dissolved; and

[0142] (2) Pour the solution obtained in step (1) into a tetrafluoroethylene mold or evenly spread it on the positive electrode sheet, control the thickness of the liquid to 0.2-2.0mm, and place it under 365nm ultraviolet light for 1-12 hours af...

Embodiment 1

[0169] Preparation of the positive electrode sheet: the weight ratio of 80% positive electrode active material battery grade LiFePO 4 , 10% binder polyvinylidene fluoride PVDF and 10% conductive agent acetylene black are dispersed in N-methylpyrrolidone, fully stirred until a viscous slurry is formed; the slurry is evenly coated on battery-grade aluminum foil, controlled Each square centimeter of aluminum foil contains about 1.5-2 mg of positive electrode active material. The solvent is dried at 80°C, cut into 14mm diameter discs, and then vacuum-dried at 120°C for 4 hours to obtain the positive electrode sheet.

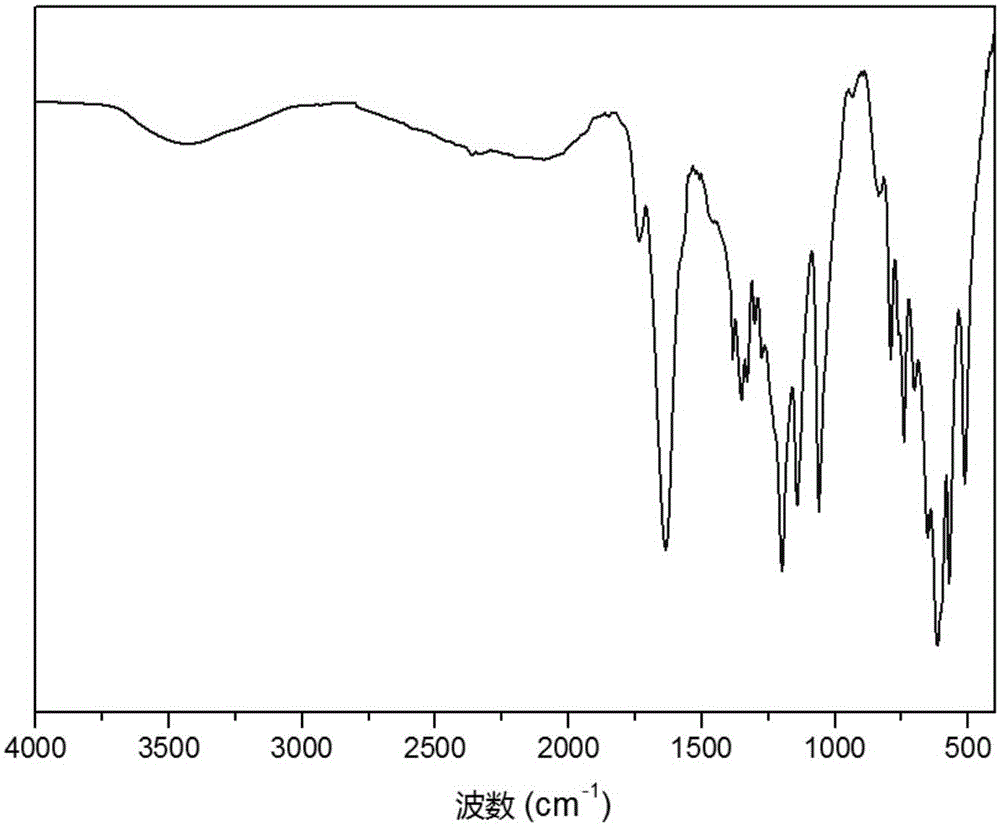

[0170] 1-methyl-3-allyl imidazolium tetrafluoroborate (AMIm-BF4), 1,3-diallyl imidazolium tetrafluoroborate (DAIm-BF4) and tetrakis (3-mercapto Propionic acid) pentaerythritol ester (PETMP, Sigma-Aldrich company product) mixes in molar ratio 1.8:1.1:1.0, then adds the photoinitiator I-907 of 1.0% by weight and 5.0% Lithium Tetrafluoroborate, dark stirring, until the...

Embodiment 2

[0172] Preparation of the positive electrode sheet: the weight ratio of 80% positive electrode active material battery grade LiFePO 4 , 10% binder polyvinylidene fluoride PVDF and 10% conductive agent acetylene black are dispersed in N-methylpyrrolidone, fully stirred until a viscous slurry is formed; the slurry is evenly coated on battery-grade aluminum foil, controlled Each square centimeter of aluminum foil contains about 1.5-2 mg of positive electrode active material, and the solvent is dried at 80° C., and then vacuum-dried at 120° C. for 4 hours.

[0173] 1-methyl-3-allyl imidazolium bistrifluoromethanesulfonimide salt (AMIm-TFSI), 1,3-diallyl imidazolium bistrifluoromethanesulfonylimide salt (DAIm- TFSI) and tetrakis (3-mercaptopropionic acid) pentaerythritol ester (PETMP) are mixed in a molar ratio of 1.9:1.05:1.0, then add 2.0% benzoin ethyl ether and 16.7% lithium bistrifluoromethanesulfonylimide (LiTFSI , Shanghai McLean Biochemical Technology Co., Ltd.), and stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com