Oil-resistant, wear-resistant and low-temperature-resistant locomotive-cable irradiation-cross-linking halogen-free flame-retardant cable material

A flame retardant cable material, locomotive cable technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problem of difficult to meet the requirements of oil resistance and low temperature resistance, achieve strong wear resistance, good flame retardant performance, good low temperature performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

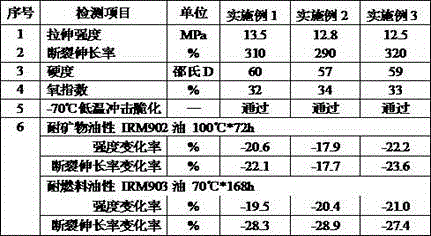

Embodiment 1~3

[0038] Examples 1-3: Irradiation cross-linked halogen-free flame-retardant cable material for oil-resistant, wear-resistant and low-temperature resistant locomotive cables

[0039] Preparation method: Mix the materials in the raw material formula according to the weight and number, put them into a high-speed mixer and mix them for 5-10 minutes, and then put them into a pressurized internal mixer for mixing. The mixing temperature is 140-150°C. Send it into a single-screw extruder for extrusion and granulation, the extrusion temperature is 110~150°C, and the extrusion speed is 200~300r / min.

[0040] The pellets are plasticized on an open mill, and the temperature of the open mill is 130~145°C.

[0041] Place the flakes in a hydraulic press at 160~170°C for 6 minutes without pressurization, then pressurize and heat for 4 minutes, the pressure is greater than 15MPa, and then pressurize and cool to room temperature.

[0042] The test piece is irradiated and cross-linked, the irra...

Embodiment 4~5

[0058] Examples 4~5: Irradiation cross-linked halogen-free flame-retardant cable material for oil-resistant, wear-resistant and low-temperature resistant locomotive cables

[0059] Preparation method is with embodiment 1~3, and raw material formula is made up of the component of following weight parts, as shown in table 3:

[0060] table 3

[0061]

[0062] Wherein, the average particle diameters of the aluminum hydroxide and magnesium hydroxide are both 0.8-1.5 μm;

[0063] The mean particle diameter of described nano zirconium carbide is 20~60nm;

[0064] The mass content of the active ingredient silicone in the silicone masterbatch is 50-55%.

[0065] The linear low-density polyethylene is metallocene linear low-density polyethylene, and the melt index is 0.08-2g / 10min.

[0066] The mass percentage of vinyl acetate in the ethylene-vinyl acetate copolymer is 40-65%, and the melt index of the ethylene-vinyl acetate copolymer is 2-10g / 10min.

[0067] The ternary nylon is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com