Feed additive and preparation method and application thereof

A feed additive and animal feed technology, applied in applications, animal feed, animal feed, etc., can solve the problems of ineffective preservation of biologically active ingredients, easy mold growth in feed additives, and reduced animal immunity, so as to improve feed conversion rate and production performance, realize waste recycling, and enhance immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Preparation of Bioactive Peptide Microcapsules

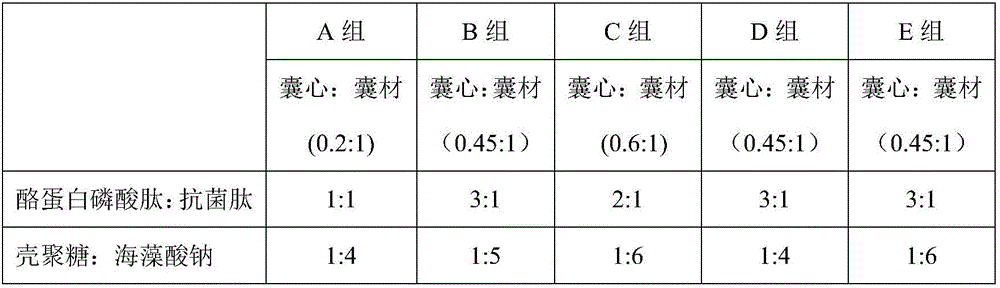

[0033] The bioactive peptide microcapsules of the present invention are respectively made of the following groups of preparation raw materials:

[0034]

[0035] Group A preparation method:

[0036] S1: Take 1g of chitosan, add acetic acid solution with a volume concentration of 1% to the chitosan according to the ratio of material to liquid 1:4, soak and swell for 60min, heat to dissolve at 45°C, add distilled water to make mass Volume concentration is 1% chitosan solution;

[0037] S2: Dissolve 4g of sodium alginate in water and stir until dissolved to make a sodium alginate solution with a mass volume concentration of 1%, then add 0.5g of casein phosphopeptide and 0.5g of antimicrobial peptide to the sodium alginate solution, and stir Until it is completely dissolved, solution A is obtained and set aside;

[0038] S3: Slowly drop solution A into 1% chitosan solution, add water to dilute to 2 times the v...

Embodiment 2

[0040] Example 2 Quality Detection of Bioactive Peptide Microcapsules

[0041] The appearance, average particle size, drug loading and encapsulation efficiency of the microcapsules prepared in groups A-E in Example 1 of the present invention were measured, and the results are shown in the table below.

[0042] Table 1 The quality test results of microcapsules of the present invention to enhance intestinal absorption of danshensu

[0043] group

[0044] The results showed that the microcapsules prepared in group B had high cysticity, smooth surface, the narrowest average particle size, and the highest drug loading and encapsulation efficiency, indicating that the microcapsules in group B were of better quality. The obtained microcapsules are used as bioactive peptide microcapsules in the feed additive preparation raw materials of the present invention.

Embodiment 3

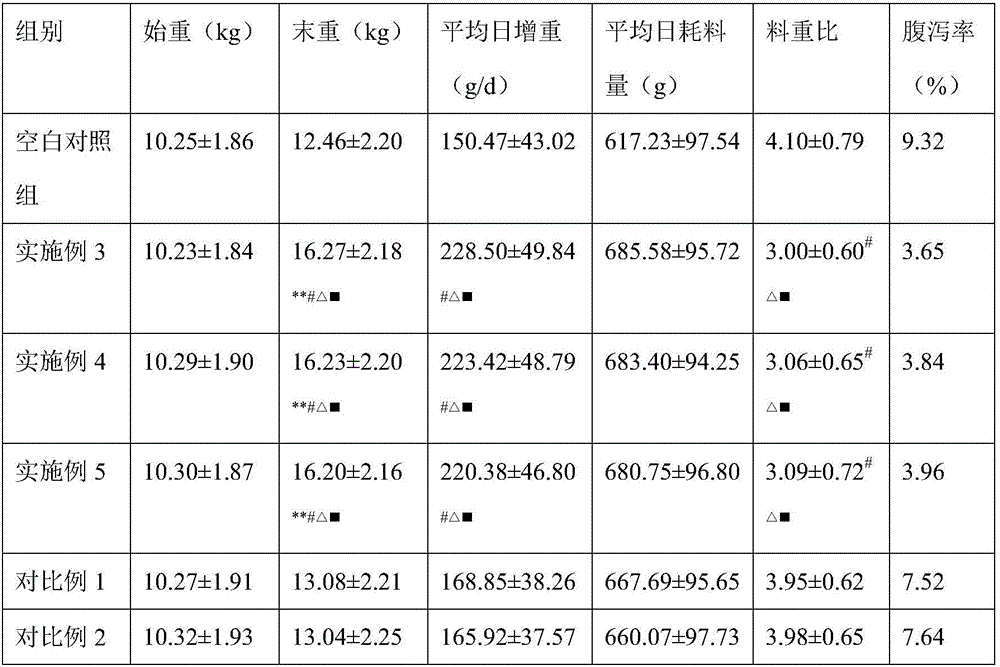

[0045] The preparation of embodiment 3 feed additives

[0046] The feed additive of the embodiment of the present invention 3 is made up of the preparation raw material of following percentage by weight:

[0047] 40% moxa powder, 25% salina powder, 15% plant extract and 20% bioactive peptide microcapsules, wherein the plant extract is composed of the following preparation raw materials in percentage by weight: oregano 45%, cinnamon 30% and ebony 25%.

[0048] Preparation:

[0049] (1) Plant extract preparation:

[0050]S1: Dried oregano and cinnamon were crushed, added ebony plums, soaked in water for 1 hour according to the ratio of material to liquid ratio of 1:10, refluxed twice for 3 hours each time, filtered and retained the filter residue, combined the filtrate to obtain water extraction liquid;

[0051] S2: Add ethanol with a volume fraction of 8 times the total weight of the filter residue to the filter residue in step S1, which is 60%, reflux extraction twice, eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com