a light diffuser

A light diffusion sheet and diffusion particle technology, applied in optics, optical components, instruments, etc., can solve the problems of complicated process and expensive equipment, and achieve the effect of simple process, cheap equipment, and smooth and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

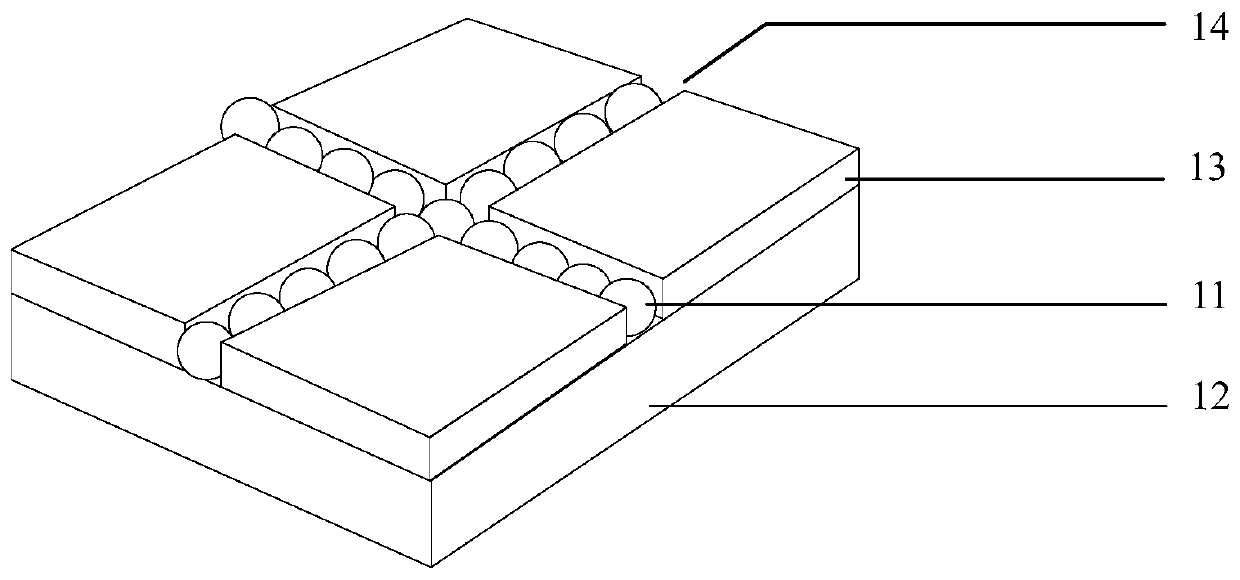

[0041] Embodiment one: see attached figure 1 As shown in , a light diffusion sheet, a structural schematic diagram of a light diffusion sheet with patterned arrangement of light diffusion particles. On the substrate 12, there are recessed structures 14, these recessed structures 14 present a preset topological arrangement, such as square, hexagonal, strip, ring, etc., the width of the recessed structure is greater than 1 micron, and the aspect ratio is greater than 0.3 . The concave structure 14 is filled with diffusion particles 11 of organic or inorganic materials. The diffusion particles 11 can be spherical, ellipsoidal, cylindrical, cuboid, or other special-shaped bodies. Different from the protective layer, the absolute difference between the optical refractive index of the diffusing particles and the refractive index of the transparent substrate layer, microstructure layer, protective layer material, or one of them is not less than 0.01. When the incident light beam pa...

Embodiment 2

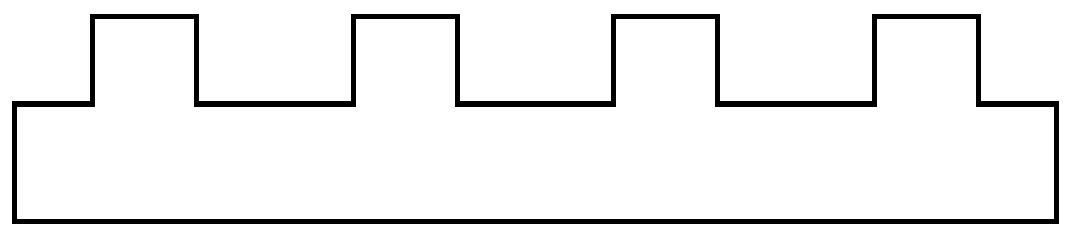

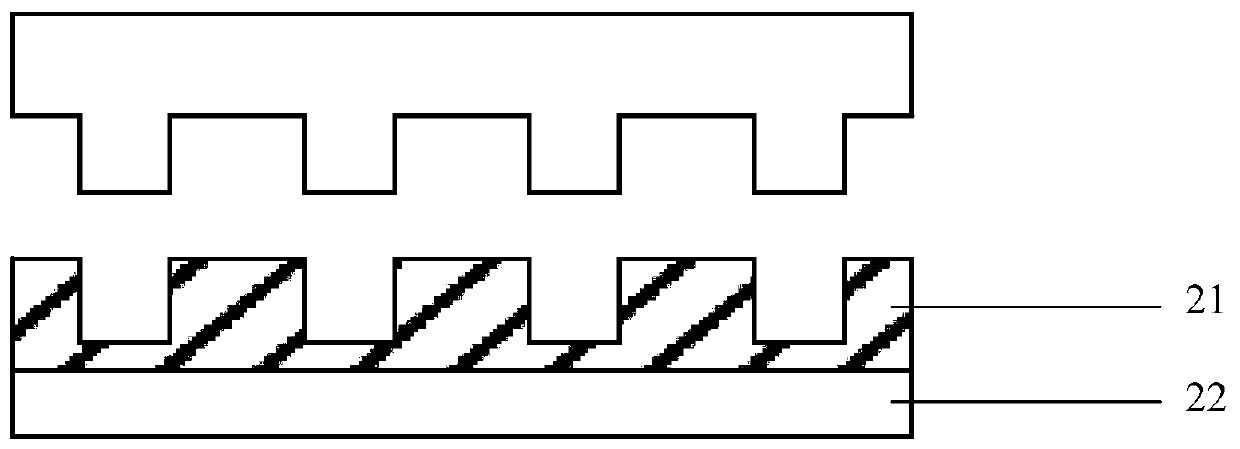

[0042] Embodiment two: see attached Figure 2a-2d As shown, the manufacturing process of a light diffusion sheet proposed by the present invention. First, a mold with a topologically arranged patterned raised structure is fabricated. Figure 2a The patterned convex structure mold in the middle can be realized by various methods, such as mask photolithography exposure, laser direct writing, chemical etching or mechanical scribing, etc. The material of the mold can be metal materials, such as nickel, stainless steel, copper or metal alloy materials, organic materials, such as polycarbonate, polyvinyl chloride, polyester, perfluoropolyetherene, tetrafluoroethylene copolymer and acrylic; Inorganic non-metallic materials such as silica, silicon, carbon steel, silicon carbide. Secondly, Figure 2b It is a schematic diagram of using a mold to make a concave structure on a transparent substrate 22 by embossing. Hot embossing or UV embossing can be used. Hot embossing is to first ...

Embodiment 3

[0043] Embodiment three: see attached Figure 3-4 As shown, in the light diffusion sheet proposed by the present invention, the shape of the concave structure filled with diffusion particles depends on the microstructure shape of the mold. Microstructure shapes such as spheres, ellipsoids, triangular pyramids, quadrangular pyramids, etc., and cross-sections of circles, ellipses, triangles, quadrilaterals or other irregular polygons, and shapes that can be filled with diffusion particles are all within the protection scope of the present invention. Diffusion particles are filled in the processed concave structure, and its state is as attached Figure 5-6 shown. When the structure on the mold has a high aspect ratio, the concave structure of the microstructure layer will also have a large aspect ratio, and the diffusion particles will be arranged in a multi-layer stacked manner in the concave structure, such as attached Figure 7 shown. This provides an additional spatial dim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com