Silicate electrode material and preparation method thereof

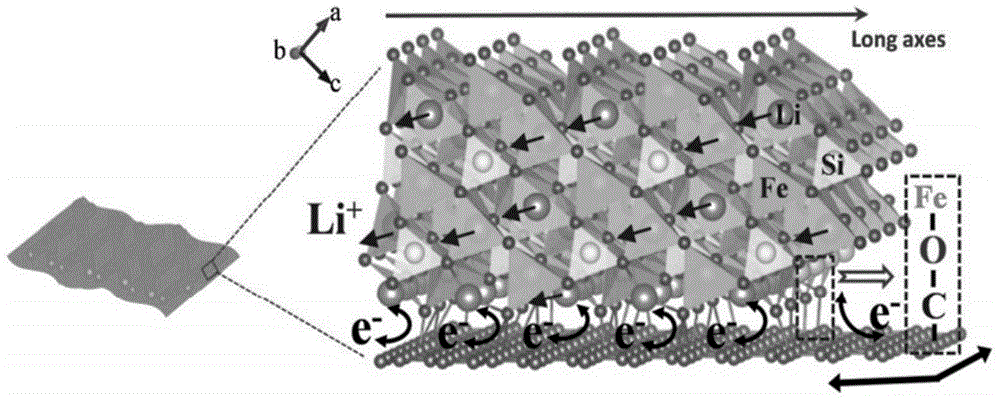

A technology of silicate and carbon materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of difficult breakthroughs in conductivity and lithium ion diffusion performance, and achieve excellent electrochemical activity, enhanced transport performance, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This example uses lithium hydroxide, ferric nitrate and tetraethyl orthosilicate to prepare silicate Li 2 FeSiO 4 , the highly conductive carbon material uses graphene, as follows:

[0039] The lithium hydroxide that takes by weighing 2.1g is dissolved in the deionized water of 50ml; The ferric nitrate Fe (NO 3 ) 3 , it was dissolved in 50ml of ethylene glycol, and 0.5g of ascorbic acid was added.

[0040] Lithium hydroxide aqueous solution, iron nitrate ethylene glycol solution and 2.8 g of tetraethyl orthosilicate were poured into a 150 ml reaction kettle, and reacted at 200° C. for 4 days to obtain a one-dimensional lithium ferrous silicate nanorod material.

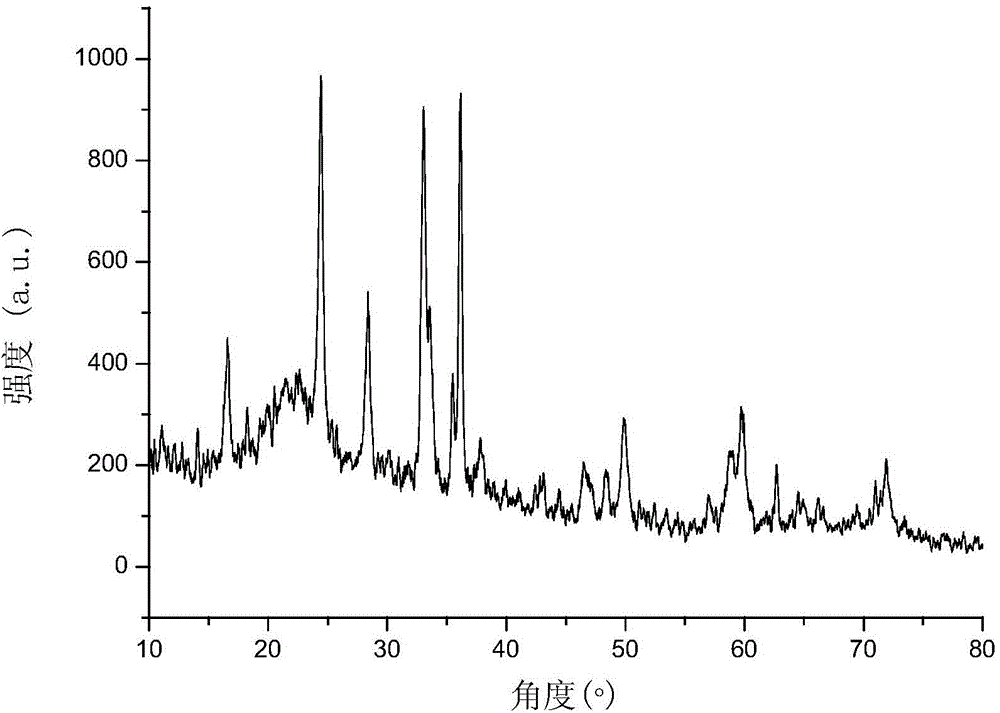

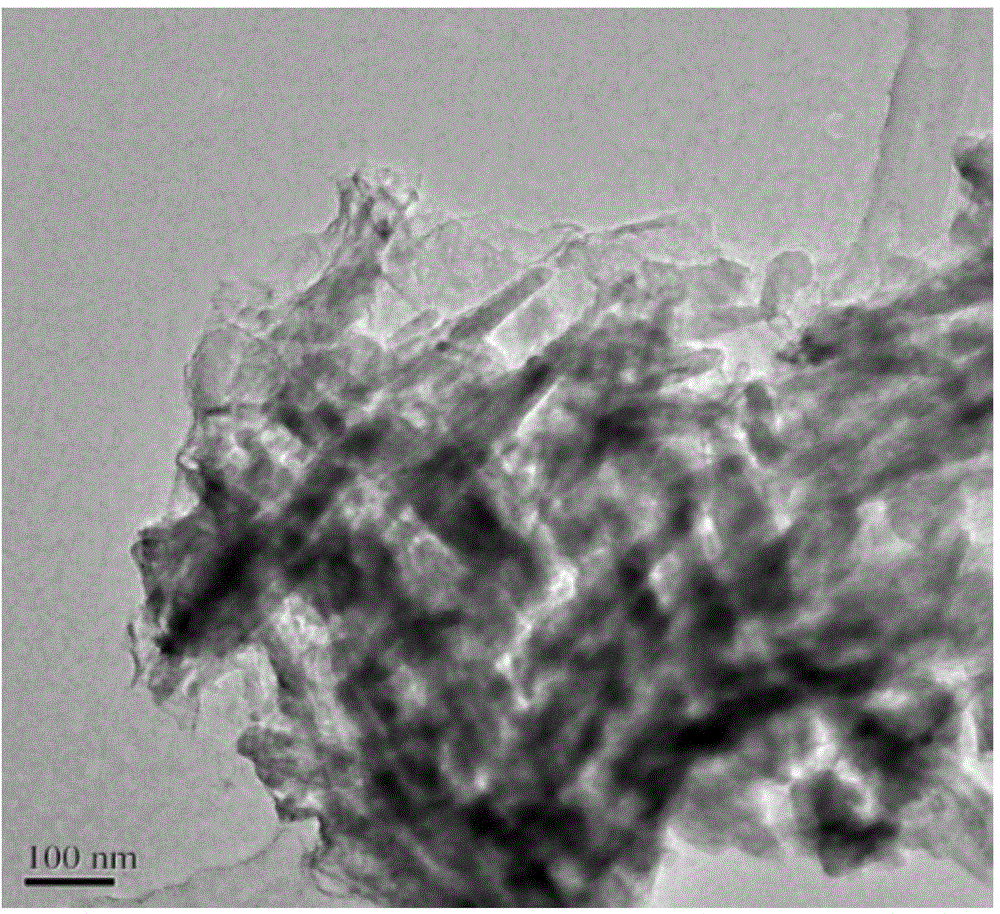

[0041] Disperse the prepared one-dimensional lithium ferrous silicate nanorod material in an aqueous solution containing 1.0 g of PVP, add graphene, stir for 30 min, freeze-dry for 2 days, and then raise the temperature at a rate of 2 °C / min to 600°C for 10 hours to obtain a two-dimensional sandwich structu...

Embodiment 2

[0052] This example adopts lithium hydroxide, manganese nitrate and tetraethyl orthosilicate to prepare silicate Li 2 MnSiO 4 , the highly conductive carbon material uses nitrogen-doped graphene, as follows:

[0053] Weigh 2.6g of lithium hydroxide, dissolve it in 40ml of deionized water; weigh 3.8g of manganese nitrate, dissolve it in 60ml of ethylene glycol, and add 1.5g of ascorbic acid.

[0054] Lithium hydroxide aqueous solution, manganese nitrate ethylene glycol solution and 3.2 g of tetraethyl orthosilicate were poured into a 150 ml reaction kettle, and reacted at 180° C. for 8 days to obtain a one-dimensional lithium manganese silicate nanorod material.

[0055] Disperse the prepared one-dimensional lithium manganese silicate nanorod material in an aqueous solution containing 2.5 g of citric acid, add nitrogen-doped graphene, stir for 50 min, freeze-dry for 2 days, and then under nitrogen atmosphere, at 2 °C / min The temperature was raised to 650°C and kept for 7 hour...

Embodiment 3

[0065] This example adopts lithium hydroxide, cobalt nitrate and tetraethyl orthosilicate to prepare silicate Li 2 CoSiO 4 , the highly conductive carbon material uses graphene quantum dots, as follows:

[0066] Weigh 2.8g of lithium hydroxide, dissolve it in 50ml of deionized water; weigh 3.1g of cobalt nitrate, dissolve it in 50ml of ethylene glycol, and add 1.0g of ascorbic acid.

[0067] Lithium hydroxide aqueous solution, cobalt nitrate ethylene glycol solution and 3.8 g tetraethyl orthosilicate were poured into a 150 ml reaction kettle, and reacted at 210° C. for 6 days to obtain a one-dimensional cobalt lithium silicate nanorod material.

[0068] Disperse the prepared one-dimensional lithium cobalt silicate nanorod material in an aqueous solution containing 1.5 g of glucose, add graphene quantum dots, stir for 40 min, freeze-dry for 2 days, and then under nitrogen atmosphere, at a speed of 2 °C / min The temperature was raised to 650° C. and kept for 8 hours to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com