A preparation method of a hybrid membrane adsorbent for removing trivalent chromium ions in water

A trivalent chromium, hybrid membrane technology, applied in chemical instruments and methods, adsorption water/sewage treatment, inorganic chemistry, etc. The flocculant has no shape report and other problems, and achieves the effects of increasing removal effect, uniform and stable surface, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

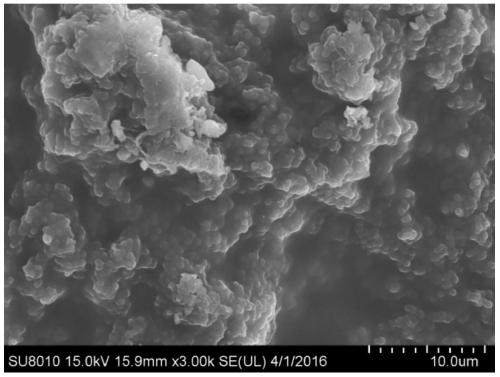

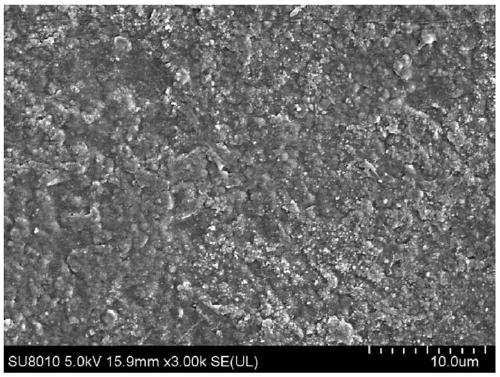

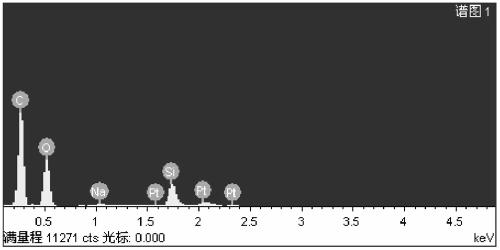

Image

Examples

Embodiment 1

[0029] The preparation steps of the hybrid membrane adsorbent and the adsorption and removal experiments of trivalent chromium ions are as follows:

[0030] (1) The preparation of the PVA aqueous solution that the mass percentage concentration is 3%: take by weighing 30g average polymerization degree and be the polyvinyl alcohol (PVA) of 1750 ± 50, add 970g distilled water, 92 ℃ of constant temperature heating in water bath (usually reaction temperature It can be at 0-100° C. (in this embodiment, the temperature is 92° C.), stirring continuously at a speed of 35 r / min until the PVA is completely dissolved. After it is completely dissolved, it is taken out, placed at room temperature and naturally cooled to obtain a PVA aqueous solution with a concentration of 3% by mass.

[0031] (2) Preparation of coating solution: in air or nitrogen atmosphere, under the temperature condition of 25°C (usually the reaction temperature can be 0-100°C, in this embodiment, it is selected under t...

Embodiment 2

[0039] Using the same experimental device, operation steps and the same proportioning ratio as in Example 1, the above-mentioned coating solution after static defoaming was impregnated into a coating film on a silica ceramic support until a diaphragm was obtained, and the diaphragm was placed Convective drying in an environment of 100° C. and relative humidity of 90% (usually, the relative humidity of membrane drying is 50-90%, and the upper limit of 90% is selected here) for 24 hours to obtain a hybrid membrane containing a support. The hybrid membrane is a hybrid membrane adsorbent that can be used to remove trivalent chromium ions in water.

[0040] The hybrid membrane prepared in this example was subjected to adsorption of 100 mg / L of Cr(NO 3 ) 3 The experiment of trivalent chromium ion in the solution, the adsorption and removal experiment results show that: under the conditions of 50 ° C and pH = 3, the hybrid film has no effect on Cr 3+ The adsorption capacity is 3.34...

Embodiment 3

[0043] Using the same experimental device, operating steps and the same proportioning ratio as in Example 1, the coating solution was first dissolved with 20 mL of N,N-dimethylformamide (abbreviated as DMF) solvent, and then the obtained substance was directly Flow the coating film on the glass plate of the support until the film is obtained, then dry it in nitrogen at 100 ° C and a relative humidity of 90% for 48 hours, and then peel off the film from the glass plate after cooling at room temperature in the air to obtain a film that does not contain The membrane-like support is a hybrid membrane that can be used to remove trivalent chromium ions from water.

[0044] The hybrid membrane prepared in this example was subjected to adsorption of 100 mg / L of Cr(NO 3 ) 3 The experiment of trivalent chromium ion in the solution, the adsorption and removal experiment results show that: under the conditions of 40 ° C and pH = 3, its effect on Cr 3+ The adsorption capacity is 3.37 mg / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com