Nickel oxide powder and preparation method thereof

A technology of nickel oxide powder and nickel salt, which is applied in the direction of nickel oxide/nickel hydroxide, etc., can solve the problems of uneven product particle size, high concentration of precipitant, easy agglomeration, etc., achieve good sintering activity, simple preparation process, and eliminate impurities low taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of embodiment of the preparation method of nickel oxide powder of the present invention, the preparation method of nickel oxide powder described in this embodiment is:

[0037] (1) add ethylenediamine in the nickel chloride aqueous solution, stir, obtain complex solution; Wherein, the mass concentration of nickel chloride in the nickel chloride aqueous solution is 100g / L, the mol ratio of nickel chloride and ethylenediamine It is 1:2.5 (that is, the molar ratio of nickel and ethylenediamine coordination atom N contained in the nickel chloride aqueous solution is 1:5);

[0038] (2) add sodium hydroxide solution in the complex compound solution gained in step (1), the mass concentration of sodium hydroxide in the sodium hydroxide solution is 100g / L, and contained sodium hydroxide and chloride in the sodium hydroxide solution The molar ratio of nickel chloride contained in the nickel aqueous solution is 2.5:1, and the pH value of the resulting mixture is controlled ...

Embodiment 2

[0043] An embodiment of the preparation method of the nickel oxide powder of the present invention, the difference between the preparation method of the nickel oxide powder described in this embodiment and the preparation method of the nickel oxide powder described in Example 1 is only in step (4) The firing temperature is different. In this embodiment, the calcination temperature in step (4) is 750°C.

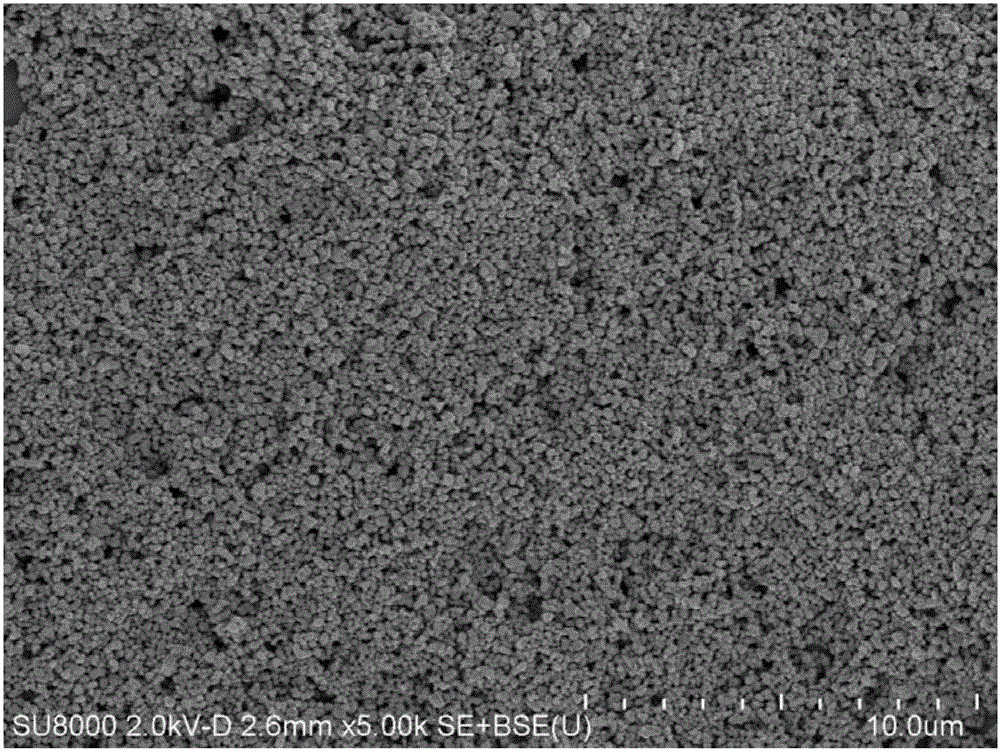

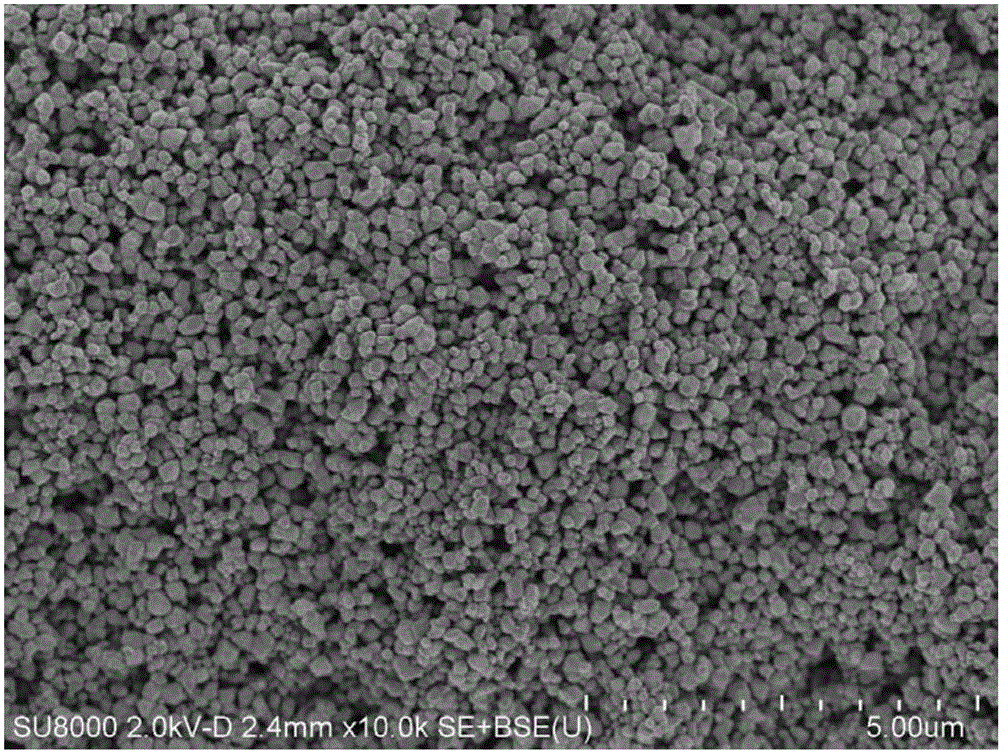

[0044] The nickel oxide micropowder that present embodiment obtains, adopts HITACHI S-3400N type scanning electron microscope (scanningelectron microscope, SEM) to analyze it, scanning electron microscope picture is as follows image 3 and Figure 4 shown. The results show that the structure of the nickel oxide micropowder in this example is a typical cubic crystal system, the morphology of the sample is basically nearly spherical, and the dispersion is good, the particle size is about 200nm, and the specific surface area is 6.8m 2 / g.

Embodiment 3

[0046] An embodiment of the preparation method of the nickel oxide powder of the present invention, the difference between the preparation method of the nickel oxide powder described in this embodiment and the preparation method of the nickel oxide powder described in Example 1 is that the chlorine in step (1) is The concentration of nickel chloride aqueous solution is different. In this embodiment, the mass concentration of nickel chloride in the nickel chloride aqueous solution is 150 g / L.

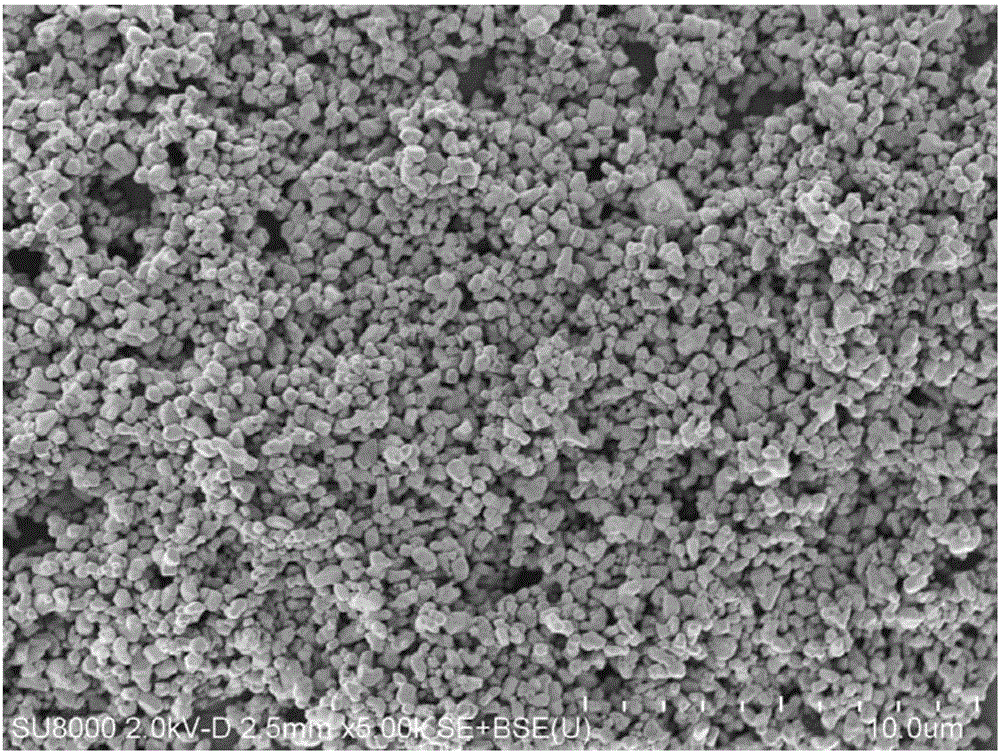

[0047] The nickel oxide micropowder that present embodiment obtains, adopts HITACHI S-3400N type scanning electron microscope (scanningelectron microscope, SEM) to analyze it, scanning electron microscope picture is as follows Figure 5 and Figure 6 shown. The results show that the structure of the nickel oxide micropowder in this example is a typical cubic crystal system, the morphology of the sample is basically nearly spherical, and the dispersion is good, the particle size is abou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com