Water-soluble fertilizer containing humic acid and special for strawberries and production method of special water-soluble fertilizer

A water-soluble fertilizer and strawberry technology, which is applied in the special water-soluble fertilizer containing humic acid strawberry and its production field, can solve the problems of human body and environmental hazards, and achieve the effects of stimulating crop growth, strengthening penetration, and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

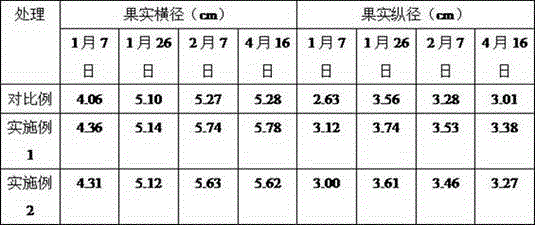

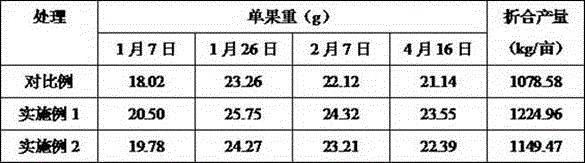

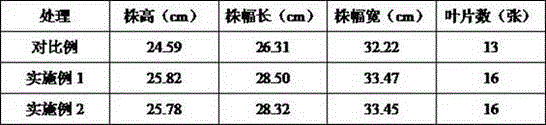

Examples

Embodiment 1

[0052] A special water-soluble fertilizer for strawberries containing humic acid, the contents of nitrogen, phosphorus and potassium are respectively 14%, 5%, and 16%, all of which are percentages by mass. The weight of the raw material components is as follows:

[0053] Humic acid substances 50kg,

[0054] Superphosphate 228kg,

[0055] Heavy superphosphate 30kg,

[0056] Potassium sulfate 320kg,

[0057] Urea 270kg,

[0058] Ammonium sulfate 80kg,

[0059] Boric acid 5.7kg,

[0060] Potassium indolebutyrate 0.1kg,

[0061]Sodium naphthalene acetate 0.2kg,

[0062] Trace element weight 1.5kg (EDTA chelated zinc 0.3kg, EDTA chelated iron 0.5kg, EDTA chelated manganese 0.3kg, EDTA chelated copper 0.4kg);

[0063] Step 1: Melt 270kg of solid urea at a high temperature of 135°C, enter the buffer tank, pressurize it through a delivery pump, and send it to the mixing tank at the top of the tower after metering.

[0064] The second step: 5.7kg boric acid, 0.3kg EDTA chelated...

Embodiment 2

[0067] A special water-soluble fertilizer for strawberries containing humic acid, the contents of nitrogen, phosphorus and potassium are respectively 15%, 6%, and 14%, all of which are percentages by mass, and the weight of the raw material components is as follows:

[0068] Humic acid substances 50kg,

[0069] Superphosphate 224kg,

[0070] Heavy SSP 54kg,

[0071] Potassium sulfate 280kg,

[0072] Urea 308kg,

[0073] Ammonium sulfate 42kg,

[0074] Boric acid 5.7kg,

[0075] Potassium indolebutyrate 0.1kg,

[0076] Sodium naphthalene acetate 0.2kg,

[0077] Trace element weight 1.5kg (EDTA chelated zinc 0.3kg, EDTA chelated iron 0.5kg, EDTA chelated manganese 0.3kg, EDTA chelated copper 0.4kg);

[0078] The preparation process is as follows:

[0079] Step 1: Melt 308kg of solid urea at a high temperature of 135°C, enter the buffer tank, pressurize it through a delivery pump, and send it to the mixing tank at the top of the tower after metering.

[0080] The second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com