Efficient-corrosion-inhibition compound chloride salt type snow-melting agent and preparation method thereof

A technology of snow melting agent and corrosion inhibitor, which is applied in the field of high-efficiency corrosion-inhibiting compound chloride salt type snow-melting agent and its preparation, can solve the problems of unsatisfactory corrosion inhibition effect and high cost, achieve excellent corrosion inhibition effect, reduce corrosion, and improve anode The effect of polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

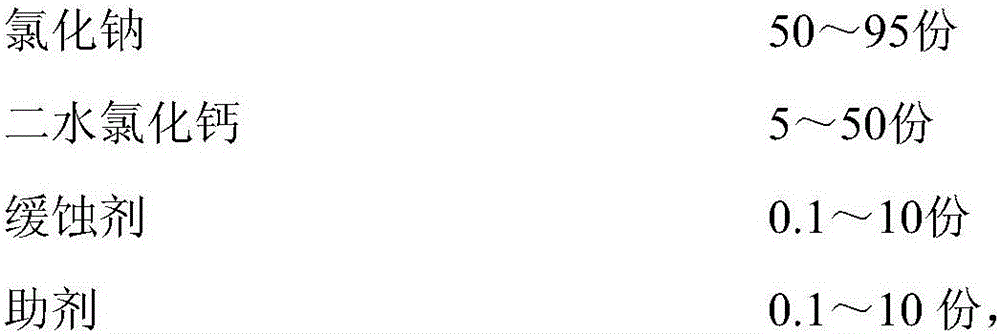

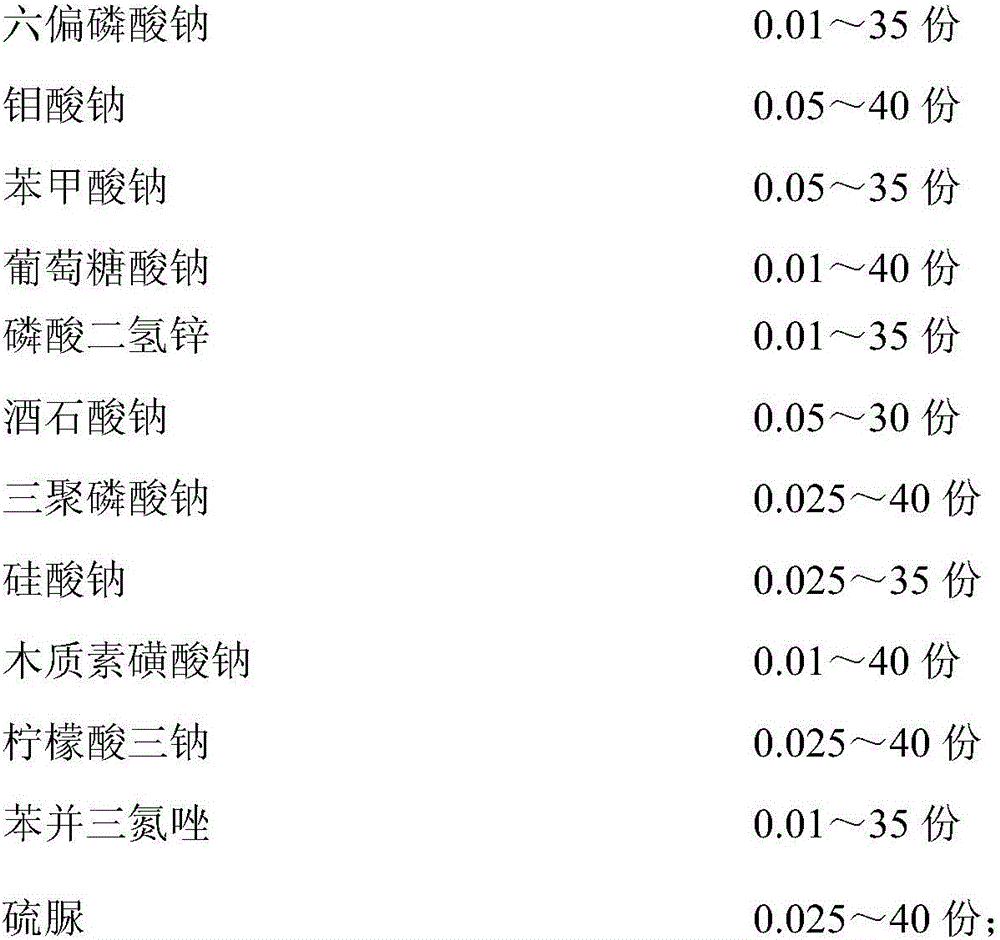

[0032] 1. Formula composition

[0033] Table 1 has listed the deicing agent of 5 embodiments and blank sample, and numerical value wherein is calculated with mass parts:

[0034] Table 1

[0035]

[0036]

[0037] 2. Metal carbon steel corrosion

[0038] In order to determine the effect of the corrosion inhibitor, refer to the rotary coupon method of DB11 / T 161-2012 for detection. The test method and test conditions are as follows:

[0039] Firstly, the deicing agent in each embodiment and blank sample in Table 1 is prepared as a corrosion solution according to the chlorine salt mass fraction of 24.0%;

[0040] The sample is a rectangular No. 20 carbon steel sheet (GB / T 699), with a size of 5mm×2.5mm×0.2mm and a surface area of 28mm 2 , the samples were wiped off the surface grease with filter paper before the experiment, soaked in acetone and absolute ethanol and dried, and finally wrapped the samples one by one with filter paper, and placed them in a desiccator fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com