Preparation method of molten salt

A technology of molten salt and salt brick, which is applied in the purification of alkali metal halides, etc., can solve problems such as harmfulness and excessive salt impurities, and achieve the effect of promoting blood circulation, simple operation process and garbage removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

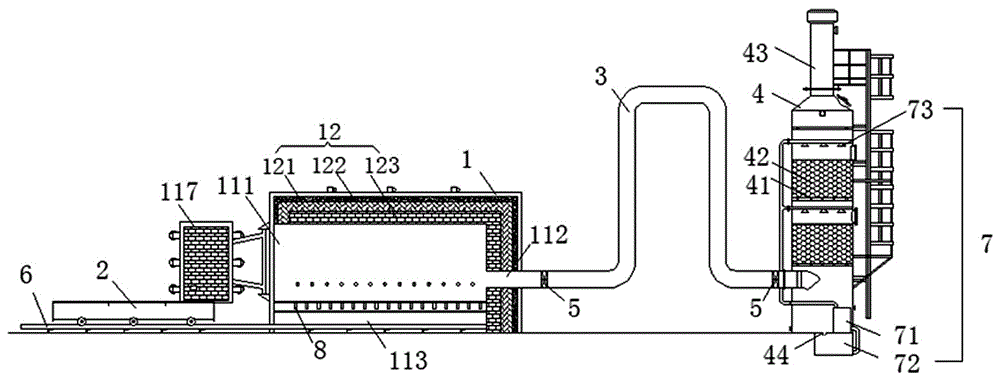

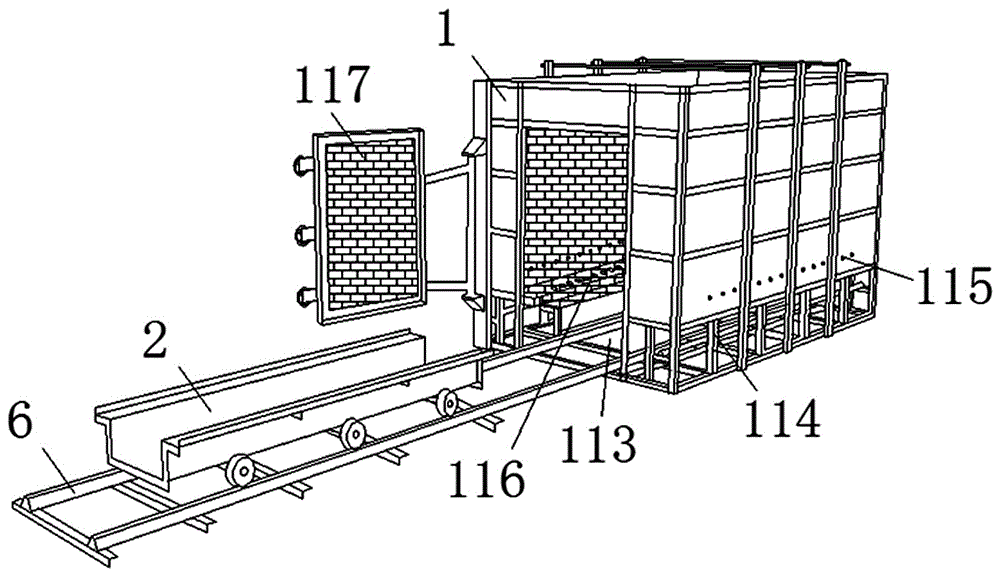

[0038] The preparation method of molten salt among the present invention, the detailed steps of this preparation method are as follows:

[0039] a. Stamping: Press the raw salt into salt bricks with a punching machine with a pressure of 800t. The specifications of the salt bricks are length x width x height = 20cmx10cmx3cm;

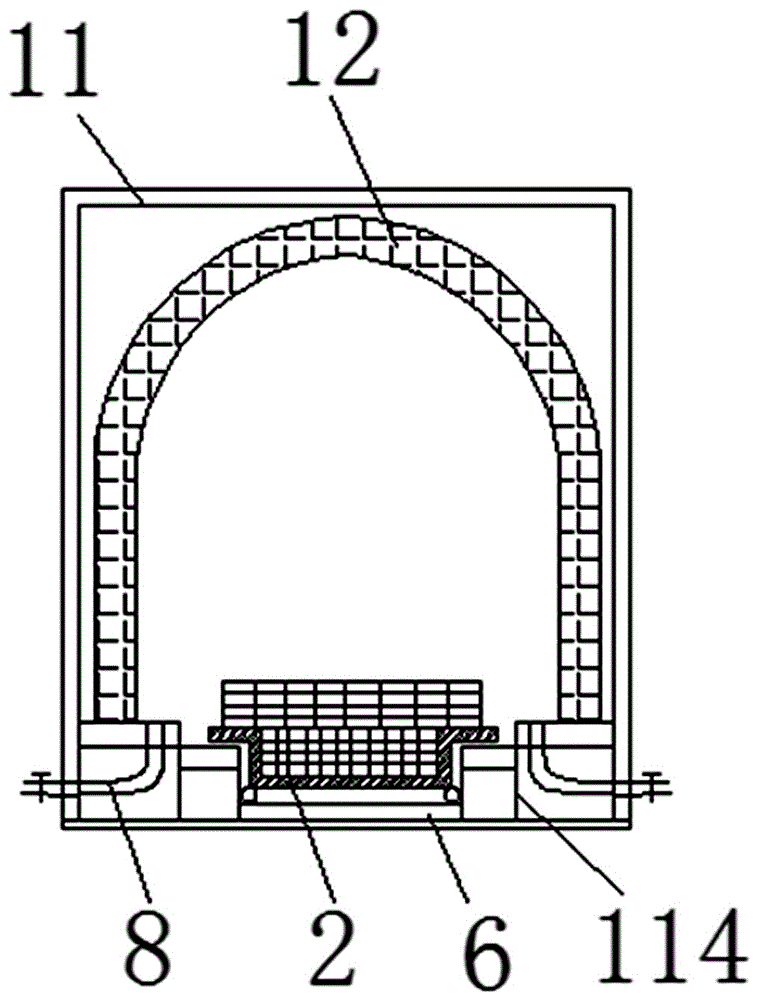

[0040] b. High-temperature firing and cooling: place the salt bricks in step a on the salt truck 2, transport the salt truck 2 to the high-temperature salt-making furnace 1, and after the temperature of the high-temperature salt-making furnace 1 reaches 700°C, Continue heating at this temperature range for 5 hours, and then reheat to 800°C until the salt brick is in the state of melting point or close to the state of melting, and then cool down in the furnace for 5h-7h to 100°C~200°C, and the salt truck 2 is produced from high temperature. Transported out of the furnace 1, and finally cooled down to normal temperature naturally;

[0041] c. Pulverization...

Embodiment 2

[0044] Basically the same as Example 1, the difference is:

[0045] In step a: the pressure of the punching machine is 400t, and the specification of the salt brick is length x width x height = 15cmx8cmx2cm;

[0046] In step b: after the temperature of the high-temperature salt furnace 1 reaches 600°C, continue heating at this temperature range for 5 hours, and then heat to 800°C until the salt brick is in a state of melting point or close to a state of melting, and then cool down in the furnace for 5 hours- 7h to 100°C~200°C, transport the salt truck 2 out of the high temperature salt furnace 1, and finally cool down to room temperature naturally;

Embodiment 3

[0048] Basically the same as Example 1, the difference is:

[0049] In step a: the pressure of the punching machine is 600t, and the specification of the salt brick is length x width x height = 20cmx10cmx3cm;

[0050] In step b: after the temperature of the high-temperature salt furnace 1 reaches 650°C, continue heating at this temperature range for 5 hours, and then reheat to 800°C; until the salt brick is in a state of melting point or close to a state of melting, then cool down in the furnace for 5 hours- 7h to 100°C~200°C, transport the salt truck 2 out of the high temperature salt furnace 1, and finally cool down to room temperature naturally;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com