Preparation method of graphene-based composite energetic material

A graphene-based material, graphene-based technology, applied in attack equipment, nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, non-explosive/non-thermal agent components, etc., can solve the problem of poor dispersion of ultrafine explosive particles , affecting the output energy of explosives, losing the properties of nano-explosives, etc., to achieve the effects of easy industrialization, simple and easy preparation methods, and reduced mechanical sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of graphene oxide (GO) mainly comprises the following steps:

[0037] Add 50mL of concentrated sulfuric acid into a three-necked flask, put it into a low temperature constant temperature reaction bath, control the temperature below 0°C, add 2g flake graphite and 1g NaNO under stirring 3 , slowly add 7g of potassium permanganate, after a period of reaction, move the three-necked flask into a water bath at 35°C, continue the reaction for 2h, and then slowly add 90ml of deionized water. After that, the temperature was raised to 90°C, and 150ml of deionized water was added to terminate the reaction, and then a certain amount of hydrogen peroxide was added to reduce the unreacted oxidant until no bubbles were generated. Finally, the graphene oxide powder is obtained after washing with dilute hydrochloric acid and deionized water, dialysis, centrifugation and drying.

[0038]Pour 0.5g of graphene oxide into 100ml of n-heptane, ultrasonically disperse e...

Embodiment 2

[0040] In this embodiment, graphene oxide (GO) adopts the graphene oxide prepared in embodiment 1.

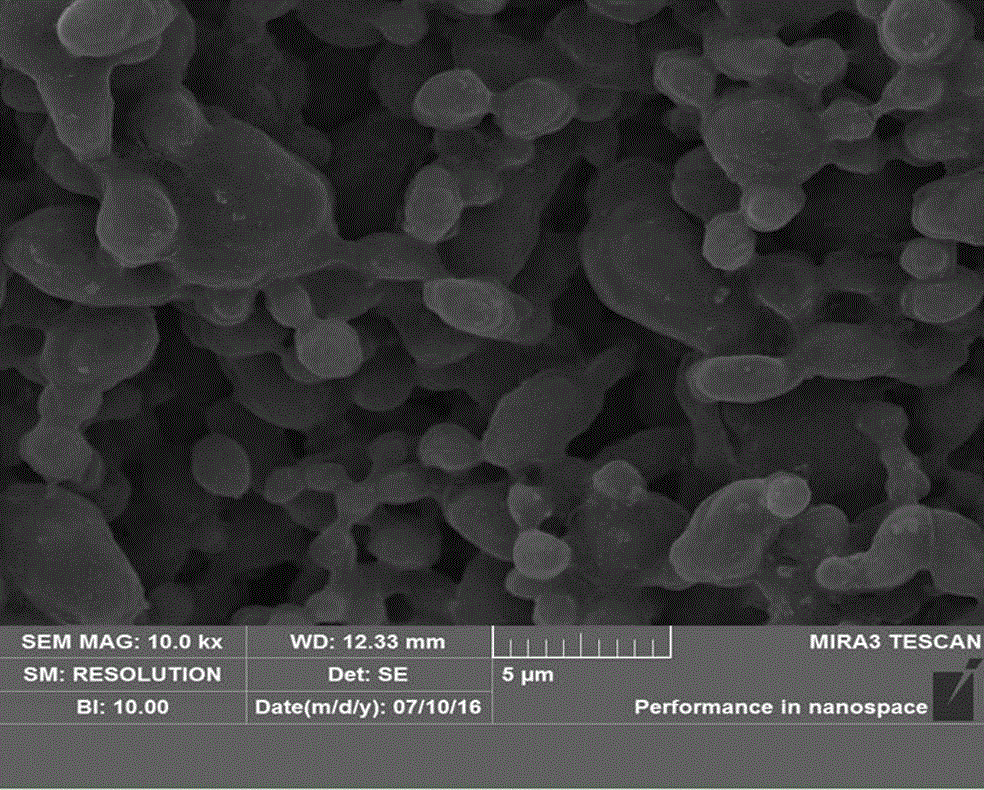

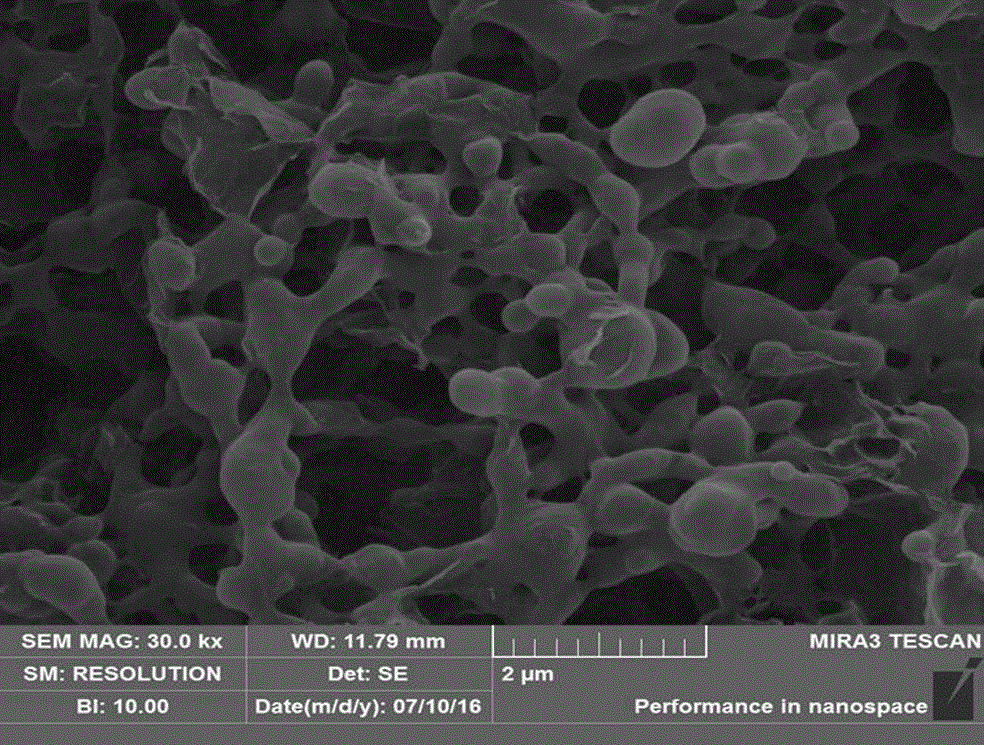

[0041] Pour 0.1g of graphene oxide into 100mL of 1,2-dichloroethane, ultrasonically disperse evenly; then pour the above suspension together with 9.9g of HMX and 200g of grinding balls into a grinding jar, stir to make it even and then seal it. The diameter of the ball mill jar is 7cm, and the diameter of the grinding ball is a mixture of 0.1mm and 0.3mm. Fix the ball mill jar on the ball mill and grind at a speed of 400r / min for 5h. Afterwards, the grinding balls were sieved, filtered, washed, and freeze-dried to obtain the HMX / graphene oxide composite energetic material.

Embodiment 3

[0043] In this embodiment, graphene oxide (GO) adopts the graphene oxide prepared in embodiment 1.

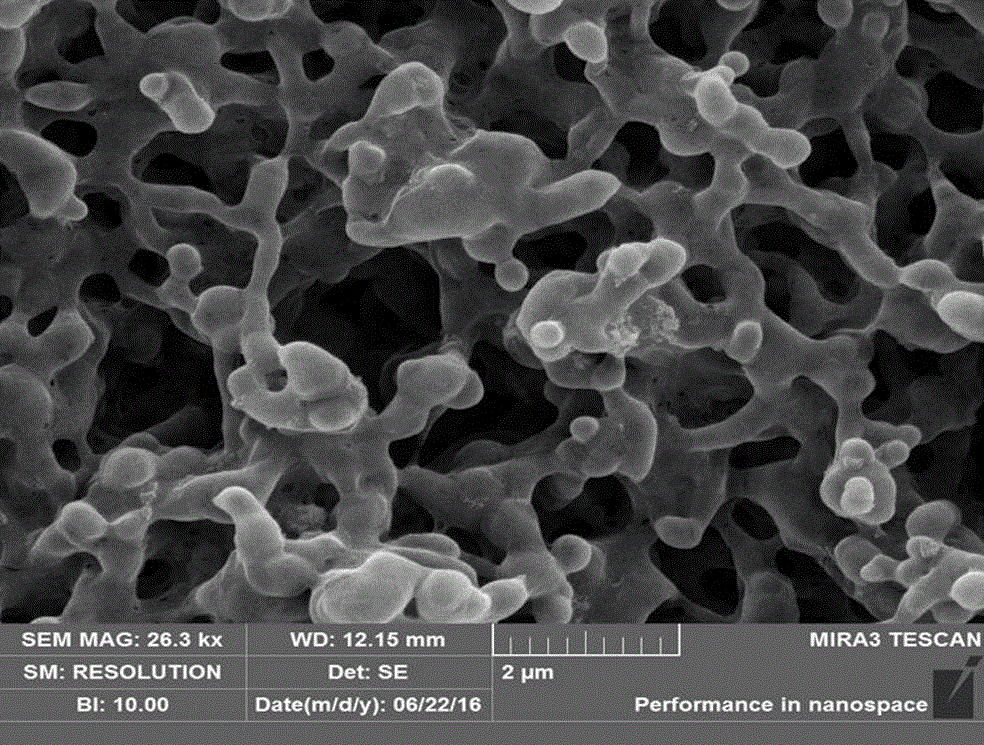

[0044] Weigh 0.5 g of graphene oxide and place in 100 mL of deionized water, and ultrasonically disperse for 30 min to obtain a stable graphene oxide aqueous dispersion. Place it in a water bath at 90°C, slowly add 2 mL of 80% hydrazine hydrate solution dropwise under mechanical stirring, and react for 4 hours, the solution turns from brown to black. The solution was suction filtered, washed and dried. The dried product was collected to obtain graphene. The prepared graphene such as Figure 4 shown, from Figure 4 It can be seen that the prepared graphene is in the form of flakes, the flakes are relatively thin, and the distance between layers is relatively large, indicating that graphene has been successfully prepared.

[0045] Pour 0.1g of graphene into 100ml of absolute ethanol, and ultrasonically disperse evenly; then pour the above suspension, 9.9g of HMX and 200g of g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com