Sunlight reflecting paint

A technology for reflecting paint and sunlight, applied in the field of sunlight reflecting paint, can solve the problems of wear resistance, impact resistance, sunlight reflectivity, poor thermal insulation, etc., and achieves a simple and easy preparation method and excellent aging resistance. , suitable for large-scale promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

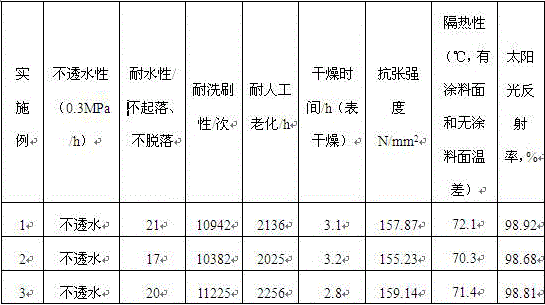

Examples

preparation example Construction

[0024] The preparation method of described solar reflection paint, comprises the following steps:

[0025] S1: Polyester resin, polyamide resin, butyl acrylate, methylpyrrolidone, alkylphenol polyoxyethylene ether, sodium dodecylbenzenesulfonate, 3-glycidyl etheroxypropyl trimethoxysilane, Paraffin wax, wollastonite powder, sodium bicarbonate, attapulgite, zinc stearate, polyvinyl chloride fiber, polypropylene fiber, polyamide fiber, benzoin, magnesium stearate, wetting agent 407, colorless cobalt, platinum catalyst and tert-butyl peroxy tert-valerate were mixed, and stirred for 1-1.5 hours at a microwave power of 180-230W, a temperature of 90-94°C, and a rotation speed of 3000-3500r / min to obtain a mixture a;

[0026] S2: Add propanol, silicon acrylic emulsion, polybutadiene rubber, polyoxyethylene polyoxypropylene pentaerythritol ether, and indene resin to the mixture a prepared in step S1, and the microwave power is 150-175W, and the temperature is 108-112 °C, stirring at ...

Embodiment 1

[0032] A kind of solar reflection paint, by weight, comprising the following raw materials: 165 parts of polyester resin, 100 parts of polyamide resin, 80 parts of butyl acrylate, 38 parts of methylpyrrolidone, 18 parts of alkylphenol polyoxyethylene ether, 15 parts of sodium dodecylbenzenesulfonate, 8 parts of 3-glycidyl etheroxypropyl trimethoxysilane, 28 parts of propanol, 15 parts of paraffin wax, 45 parts of silicon acrylic emulsion, 6 parts of wollastonite powder, bicarbonate 7 parts of sodium, 8 parts of attapulgite, 6 parts of zinc stearate, 5 parts of polyvinyl chloride fiber, 8 parts of polypropylene fiber, 6 parts of polyamide fiber, 1 part of benzoin, 0.8 part of magnesium stearate, wetting agent 0.6 parts of 407, 0.6 parts of colorless cobalt, 0.5 parts of platinum catalyst, 0.4 parts of tert-butyl peroxyvalerate, 0.6 parts of polybutadiene rubber, 0.6 parts of polyoxyethylene polyoxypropylene pentaerythritol ether, 0.8 parts of indene resin , 1.5 parts of p-hydro...

Embodiment 2

[0041] A kind of solar reflection paint, by weight, comprising the following raw materials: 150 parts of polyester resin, 80 parts of polyamide resin, 60 parts of butyl acrylate, 30 parts of methyl pyrrolidone, 15 parts of alkylphenol polyoxyethylene ether, 12 parts of sodium dodecylbenzenesulfonate, 5 parts of 3-glycidyl etheroxypropyl trimethoxysilane, 25 parts of propanol, 12 parts of paraffin wax, 35 parts of silicon acrylic emulsion, 4 parts of wollastonite powder, bicarbonate 5 parts of sodium, 6 parts of attapulgite, 5 parts of zinc stearate, 3 parts of polyvinyl chloride fiber, 6 parts of polypropylene fiber, 4 parts of polyamide fiber, 0.7 part of benzoin, 0.6 part of magnesium stearate, wetting agent 0.4 parts of 407, 0.4 parts of colorless cobalt, 0.3 parts of platinum catalyst, 0.3 parts of tert-butyl peroxyvalerate, 0.5 parts of polybutadiene rubber, 0.4 parts of polyoxyethylene polyoxypropylene pentaerythritol ether, 0.6 parts of indene resin , 1.2 parts of p-hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com