Composite plant enzyme and applications thereof

A plant enzyme and enzyme technology, applied in the field of food processing, can solve the problems of enzyme activity destruction, enzyme destruction, enzyme reduction, etc., and achieve the effects of relieving flatulence, removing blood toxins, and restoring health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

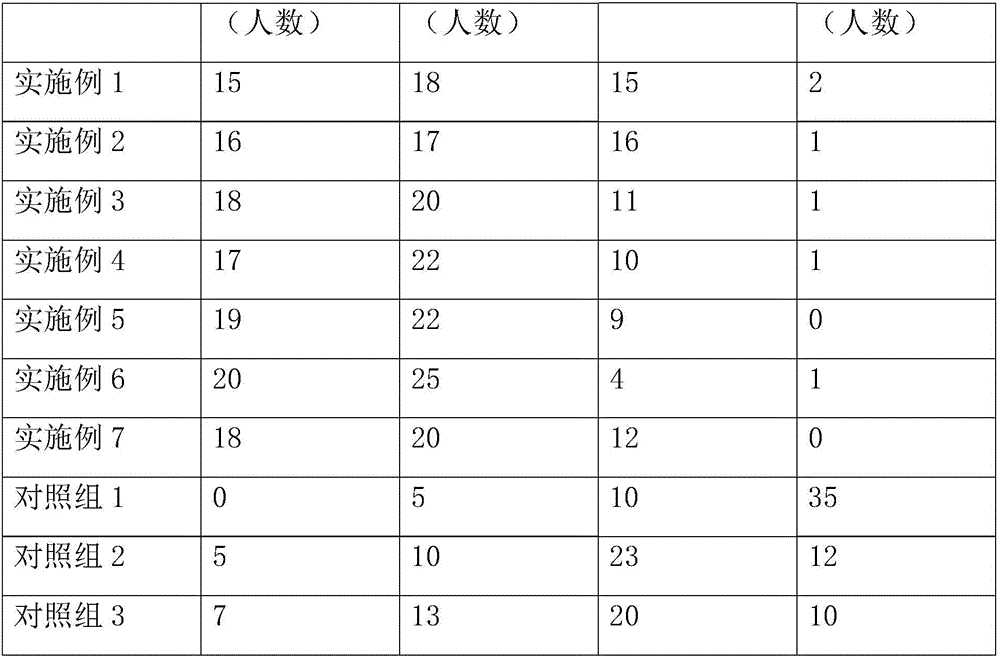

Examples

Embodiment 1

[0035] A compound plant enzyme, which is formed by mixing the following raw materials in parts by weight:

[0036] 1 part of lipolytic enzyme, 0.5 part of amylase, 0.5 part of bromelain, 0.2 part of cordyceps militaris enzyme, 0.2 part of papaya enzyme, 0.2 part of fibrinase, 20 parts of inulin.

[0037] Lipase, amylase, bromelain, cordyceps militaris enzyme, papaya enzyme, fibrinase and inulin were all purchased from the market.

Embodiment 2

[0039] A compound plant enzyme, which is formed by mixing the following raw materials in parts by weight:

[0040] 8 parts of lipolytic enzyme, 5 parts of amylase, 5 parts of bromelain, 2 parts of cordyceps militaris enzyme, 2 parts of papaya enzyme, 2 parts of fibrinase, 50 parts of inulin.

[0041] Lipase, amylase, bromelain, cordyceps militaris enzyme, papaya enzyme, fibrinase and inulin were all purchased from the market.

Embodiment 3

[0043] A compound plant enzyme, which is formed by mixing the following raw materials in parts by weight:

[0044] 2 parts of lipolytic enzyme, 1 part of amylase, 1 part of bromelain, 0.5 part of cordyceps militaris enzyme, 0.5 part of papaya enzyme, 0.5 part of fibrinase, 25 parts of inulin.

[0045]Among them, the lipolytic enzyme is that Candida is fermented with the medium of the following components, and the medium is composed of: olive oil 2.3% ± 0.2 (V / V), glucose 9 ± 0.2g / L, yeast extract 3.2 ± 0.2g / L, protein 8±0.2g / L, urea 2.1±0.2g / L, K 2 HPO 4 It is 1.9±0.2g / L; the fermentation conditions are: culture at 30±2°C for 20 hours, shaker speed 300r / min, then obtain lipase complex by saturated ammonium sulfate precipitation, and then remove ammonium sulfate by ultrafiltration to obtain fat hydrolytic enzymes;

[0046] Papaya enzyme is prepared by the following method: slice papaya, mix it with brown sugar, white sugar, acid protease and purified water as a fermented pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com