Pompom-shaped zinc oxide/graphene composite adsorbent and its preparation method and application

A graphene composite and zinc oxide technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, alkali metal compounds, etc., can solve problems such as easy secondary stacking, and achieve enhanced mechanical and chemical stability performance, ease of recycling and reuse, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A preparation method of fluffy zinc oxide / graphene composite adsorbent, comprising the following steps:

[0028] A, using graphite as a raw material, adopting the Hummer method to synthesize graphene oxide, dispersing the prepared graphene oxide into an aqueous solution to form a stable graphene oxide suspension;

[0029] B, dissolving the metal zinc salt in the graphene oxide suspension obtained in step A; then weighing a certain amount of sodium tartrate and adding it to obtain the graphene oxide suspension containing the metal zinc salt;

[0030] C, configure a precipitant solution with a molar concentration of 0.05 M ~ 4 M, and add it dropwise to the graphene oxide suspension containing metal zinc salt obtained in step B under stirring conditions of 500 rpm ~ 2000 rpm middle;

[0031] D, transfer the suspension obtained in step C into a polytetrafluoroethylene liner, react for 6 h to 72 h under 90 ° C ~ 180 ° C hydrothermal conditions, naturally cool to room temperat...

Embodiment 1

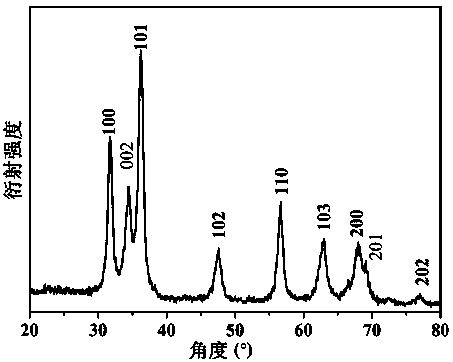

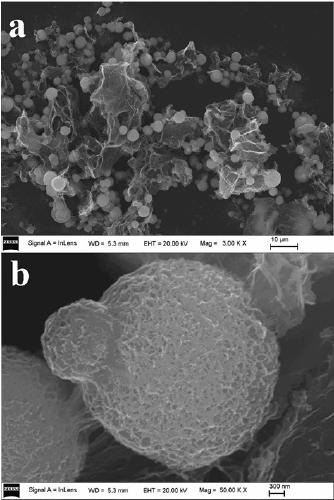

[0039] Accurately weigh 0.1 g of graphene oxide prepared by the Hummer method, and ultrasonically disperse it in 60 mL of aqueous solution to form suspension A; accurately weigh 0.001 mol of zinc nitrate hexahydrate and dissolve it in suspension A, the concentration of zinc salt Accurately weigh sodium tartrate according to the molar ratio of sodium tartrate to metal zinc salt of 1:15, dissolve it in suspension A, and form suspension B after ultrasonic dispersion for 3 minutes; prepare another 20 mL The hexamethylenetetramine solution with a concentration of 0.5 M was added dropwise to the suspension B under the stirring condition of 500~2000 rpm, and the reaction was carried out under 120 °C hydrothermal condition for 24 hours after the addition was completed. , naturally cooled to room temperature after the reaction, suction filtered and washed to obtain a fluffy zinc oxide / graphene composite adsorbent. Among them, the mass percentage of zinc oxide is 42%. The pompom-shaped ...

Embodiment 2

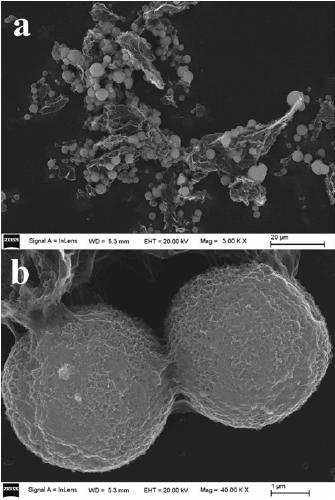

[0042] Accurately weigh 0.1 g of graphene oxide prepared by the Hummer method, and ultrasonically disperse it in 60 mL of aqueous solution to form suspension A; accurately weigh 0.001 mol of zinc chloride and dissolve it in suspension A, the concentration of zinc salt is 0.0167 M, and then accurately weigh sodium tartrate according to the molar ratio of sodium tartrate to metal zinc salt of 1:15, dissolve it in suspension A, and form suspension B after ultrasonic dispersion for 3 minutes; another 20 mL The urea solution with a concentration of 1 M is added dropwise to the suspension B under the stirring condition of 500~2000 rpm, and reacted under 180 °C hydrothermal conditions for 6 hours after the addition is completed, and naturally cooled after the reaction to room temperature, suction filtration and washing to obtain a fluffy zinc oxide / graphene composite adsorbent. Among them, the mass percentage of zinc oxide is 39%. The pompom-shaped ZnO nano / microstructure is composed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com