Preparation method of water-dispersive ternary mixed-crystal nano titanium dioxide photocatalyst

A nano-titanium dioxide and photocatalyst technology, applied in the field of photocatalysis, can solve the problems of unspecified particle size and different surface properties, and achieve the effects of easy control of the synthesis process, high catalytic activity, and high photocatalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

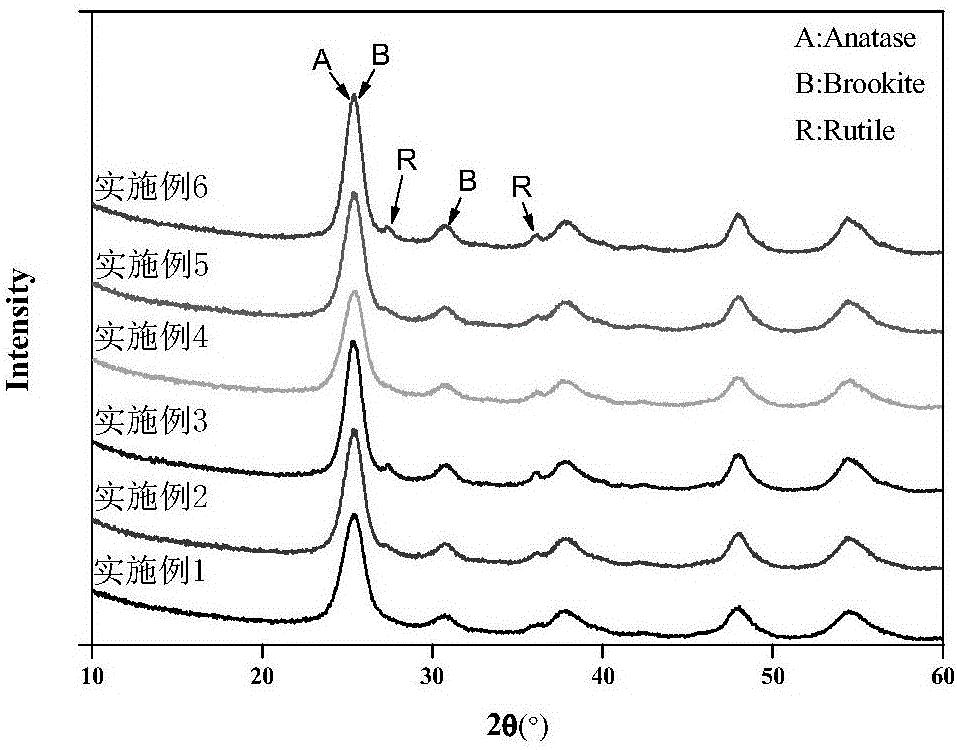

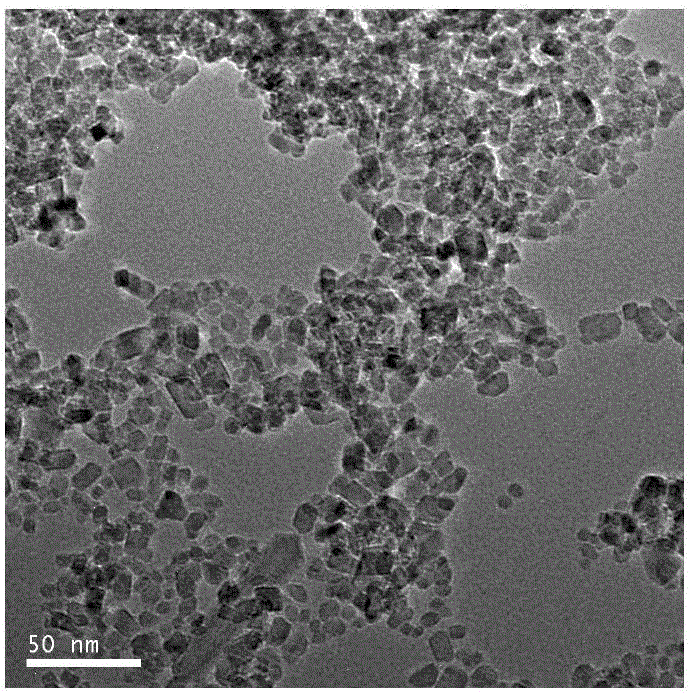

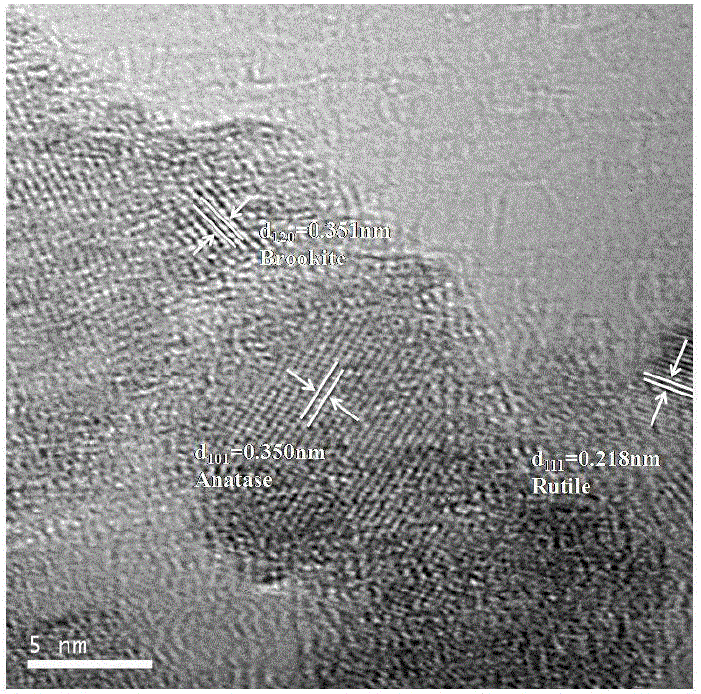

[0034] 15ml of tetrabutyl titanate was mixed with 35ml of methanol, and 2ml of 37wt% acetic acid aqueous solution was added to obtain a titanium alkoxide solution. Mix 15ml of water with 15ml of methanol to obtain an aqueous alcohol solution. Under magnetic stirring, the alcoholic aqueous solution was added to the titanium alkoxide solution, and the mixed solution was poured into a reaction kettle, and left to stand for 5 minutes to obtain a gel. The reaction kettle was put into an oven at 150° C. for 8 hours to carry out the reaction. After natural cooling, centrifugation, washing, drying and grinding, a product with a particle size of about 12nm, containing 33.9% anatase, 60.6% brookite and 5.5% rutile, and water-dispersible was obtained.

Embodiment 2

[0036] 15ml of isopropyl titanate was mixed with 35ml of methanol, and 1.5ml of 37wt% hydrochloric acid was added to obtain a titanium alkoxide solution. Mix 15ml of water with 15ml of methanol to obtain an aqueous alcohol solution. Add the aqueous alcohol solution into the titanium alkoxide solution, mix evenly, pour it into the reaction kettle, and let it stand for 5 minutes to obtain a gel. The reaction kettle was put into an oven at 160° C. for 12 hours to carry out the reaction. After natural cooling, centrifugation, washing, drying and grinding, a product with a particle size of about 12nm, containing 33.0% anatase, 60.7% brookite and 6.3% rutile, and water-dispersible was obtained.

Embodiment 3

[0038] 20ml of isopropyl titanate was mixed with 30ml of methanol, and 2ml of 37wt% hydrochloric acid was added to obtain a titanium alkoxide solution. Mix 15ml of water with 15ml of methanol to obtain an aqueous alcohol solution. Add the aqueous alcohol solution into the titanium alkoxide solution, mix evenly, pour it into the reaction kettle, and let it stand for 3 minutes to obtain a gel. The reaction kettle was put into an oven at 160° C. for 12 hours to carry out the reaction. After natural cooling, centrifugation, washing, drying and grinding, a product with a particle size of about 12nm, containing 33.5% anatase, 59.3% brookite and 7.2% rutile, and water-dispersible was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com