Preparation method of chitosan type crude oil desalting demulsifier

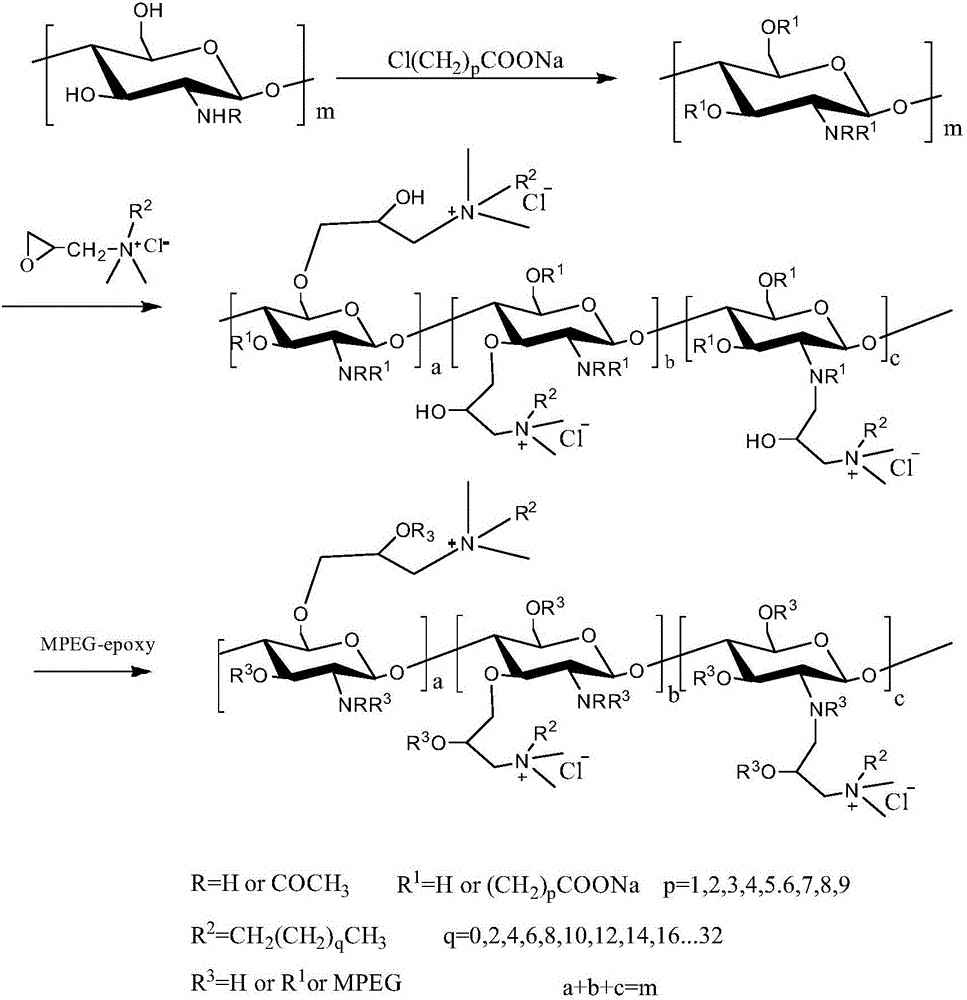

A demulsifier and saccharide technology, applied in the field of preparation of chitosan crude oil desalination demulsifier, can solve the problems of metal cation removal and weak binding ability, and achieve high molecular weight, good use safety, and increased demulsification. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

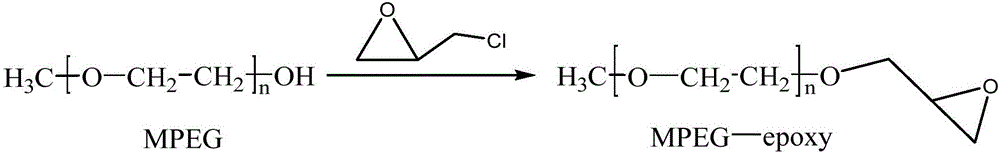

[0042] A kind of preparation of chitosan crude oil desalting demulsifier comprises the steps:

[0043] (1) Epoxidation modification of polyethylene glycol monomethyl ether terminal hydroxyl group: get polyethylene glycol monomethyl ether (Mn=350) 1.75g (5mmol) and dissolve in 50mL anhydrous toluene, add 50mL tetrahydrofuran and 0.18g (7.5mmol) of sodium hydride reagent was heated up to 25°C and reacted for 2h. 1.6mL (20mmol) of epichlorohydrin was slowly added dropwise to the reaction solution at a temperature of 40°C and reacted for 6h. The reaction solution was added to 200 mL of diethyl ether, filtered with suction, washed several times with diethyl ether, dried in vacuo, dissolved in 200 mL of dichloromethane, washed with distilled water three times, separated, dried with anhydrous magnesium sulfate, and the filtrate Pressure distillation, freeze-drying to obtain epoxidized polyethylene glycol monomethyl ether.

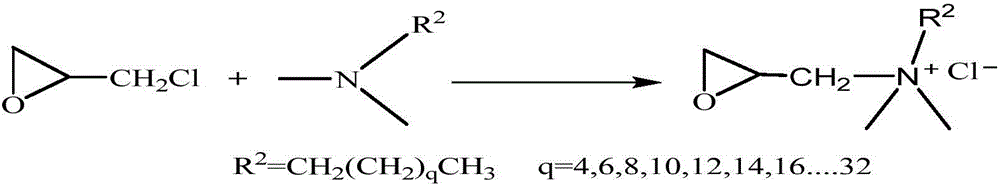

[0044] (2) Preparation of glycidyl dimethyl dodecyl ammo...

Embodiment 2

[0049] A kind of preparation of chitosan crude oil desalting demulsifier comprises the steps:

[0050] (1) Epoxidation modification of polyethylene glycol monomethyl ether terminal hydroxyl group: get polyethylene glycol monomethyl ether (Mn=750) 3.75g (5mmol) and dissolve in 50mL anhydrous toluene, add 50mL tetrahydrofuran and 0.24g (10mmol) of sodium hydride reagent was heated up to 20°C and reacted for 4h. 2.4mL (30mmol) of epichlorohydrin was slowly added dropwise to the reaction solution at a temperature of 35°C and reacted for 10h. The reaction solution was added to 200 mL of diethyl ether, filtered with suction, washed several times with diethyl ether, dried in vacuo, dissolved in 200 mL of dichloromethane, washed with distilled water three times, separated, dried with anhydrous magnesium sulfate, and the filtrate Pressure distillation, freeze-drying to obtain epoxidized polyethylene glycol monomethyl ether.

[0051] (2) Preparation of glycidyl dimethyltetradecyl ammo...

Embodiment 3

[0056] A kind of preparation of chitosan crude oil desalting demulsifier comprises the steps:

[0057] (1) Epoxidation modification of polyethylene glycol monomethyl ether terminal hydroxyl group: take polyethylene glycol monomethyl ether (Mn=1000) 5g (5mmol) and dissolve in 50mL anhydrous toluene, add 50mL tetrahydrofuran and 0.36 g (15mmol) of sodium hydride reagent, heated to 30°C, and reacted for 2h. 3.2mL (40mmol) of epichlorohydrin was slowly added dropwise to the reaction solution at a temperature of 30°C and reacted for 16h. The reaction solution was added to 200 mL of diethyl ether, filtered with suction, washed several times with diethyl ether, dried in vacuo, dissolved in 200 mL of dichloromethane, washed with distilled water three times, separated, dried with anhydrous magnesium sulfate, and the filtrate Pressure distillation, freeze-drying to obtain epoxidized polyethylene glycol monomethyl ether.

[0058] (2) Preparation of glycidyl dimethyl cetyl ammonium chlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com