Method for improving properties of non-volatile floating-gate organic thin film transistor type memorizer

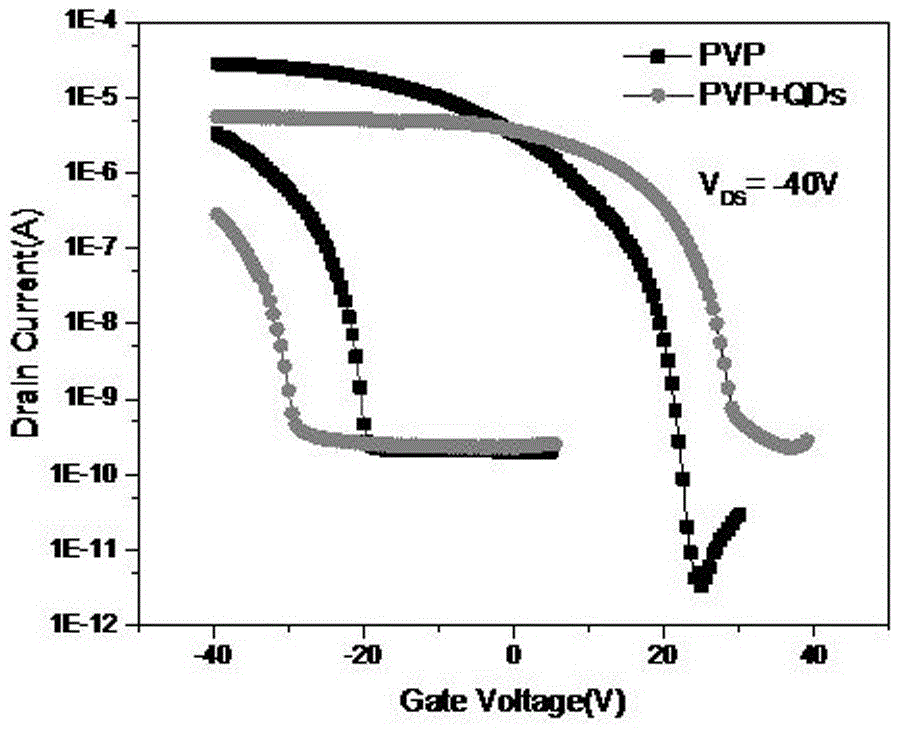

An organic thin film and transistor technology, which is applied in the field of organic photoelectric materials, can solve the problems of poor retention characteristics and small memory windows, and achieve the effects of enhancing the ability to capture charges, improving performance, and strong charge-capturing capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

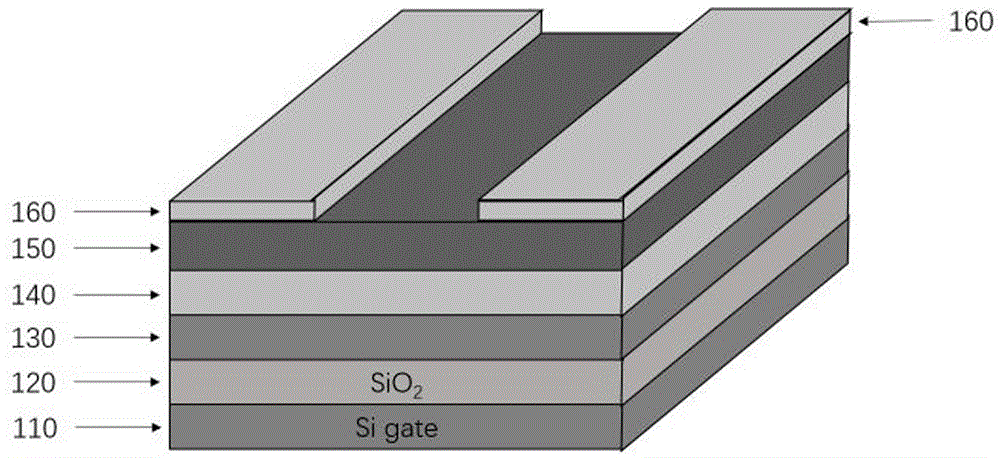

[0044] 1) A heavily doped P-type silicon wafer with a size of about 1.5cm×2.0cm grown with silicon dioxide with a thickness of 100nm is used as a substrate after cleaning with acetone, isopropanol, chloroform, deionized water, etc. and drying with nitrogen.

[0045] 2) Dissolve the organic insulating polymer PVP in a propylene glycol methyl ether acetate solvent at a ratio of 15 mg / ml, and stir at normal temperature for 48 hours to completely dissolve it. This solution was used as the charge storage layer material, filtered with a filter plug, and spin-coated on the silicon wafer substrate obtained in step 1). The spin coating speed is firstly low speed 600rpm / min, time is 5s, and then high speed 2000rpm / min, time is 30s. After spin coating, it was annealed in a glove box for 2 h.

[0046] 3) A layer of aluminum oxide film with a thickness of 4 nm is deposited on the silicon wafer obtained in step 2) by means of atomic layer deposition.

[0047] 4) Dissolve the semiconductin...

Embodiment 2

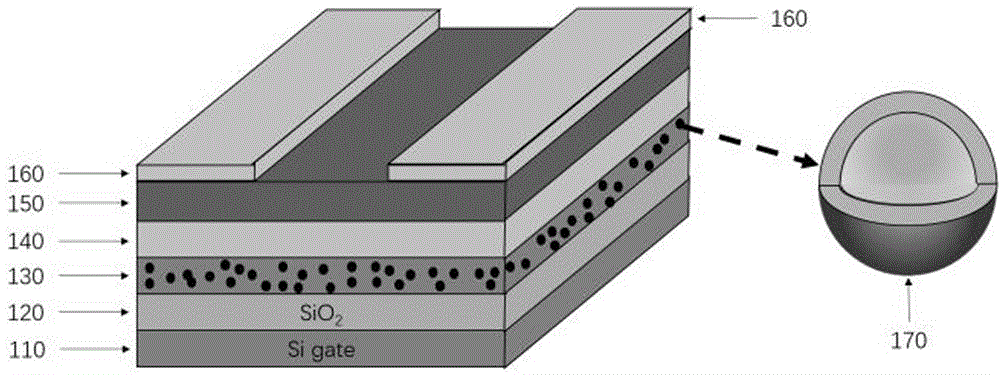

[0050] 1) A heavily doped P-type silicon wafer with a size of about 1.5cm×2.0cm grown with silicon dioxide with a thickness of 100nm is used as a substrate after cleaning with acetone, isopropanol, chloroform, deionized water, etc. and drying with nitrogen.

[0051] 2) Dissolve the organic insulating polymer PVP in the propylene glycol methyl ether acetate solvent at a ratio of 15mg / ml, and stir it at room temperature for 48 hours to make it completely dissolved, and dissolve the CdSe / ZnS quantum dots at a ratio of 3mg / ml. Dissolve in chloroform, and then mix the completely dissolved PVP solution and quantum dot solution in a volume ratio of 5:2. This mixed solution is used as the charge storage layer material, filtered with a filter plug, and spin-coated on the silicon wafer substrate obtained in step 1). The spin coating speed is firstly low speed 600rpm / min, time is 5s, and then high speed 2000rpm / min, time is 30s. After spin coating, it was annealed in a glove box for 2 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com