Efficient de-oiling agent for water generated by oil field polymer flooding

A degreaser and polymer technology, which is used in grease/oily substance/float removal devices, flocculation/sedimentation water/sewage treatment, liquid separation, etc. It is suitable for the degreasing treatment of polymer-containing sewage, and achieves the effects of strong neutralization ability, improved degreasing efficiency and high degreasing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: Degreaser A 1 and its preparation method

[0025] (1) Degreaser A 1 The composition and components are as follows:

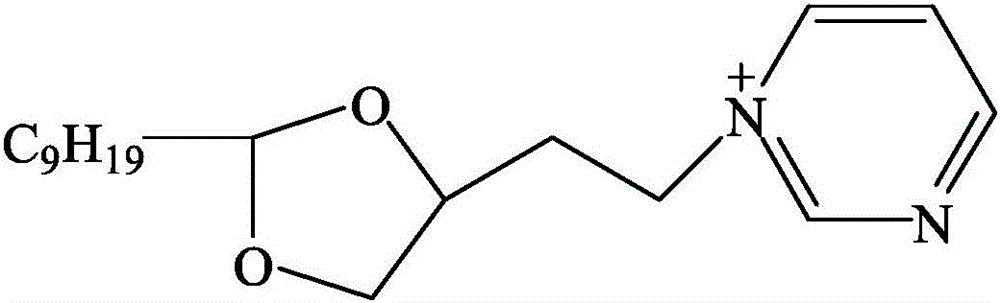

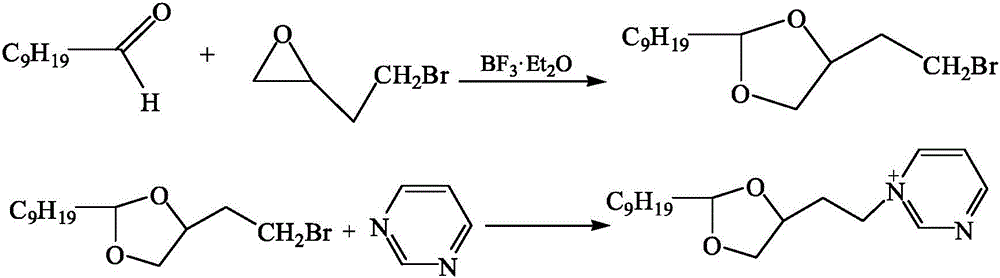

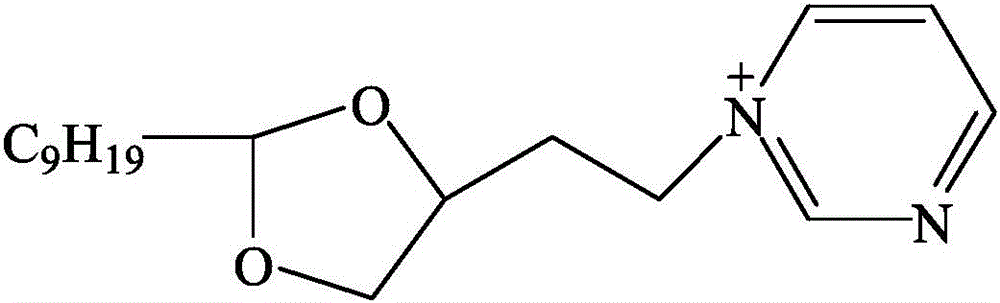

[0026] Degreaser A 1 It is an intermediate formed by the reaction of n-decyl aldehyde with bromobutylene epoxy under the catalysis of boron trifluoride ether solution, and then reacted with pyrimidine to form a cationic degreasing agent. Its molecular formula is as follows:

[0027]

[0028] Wherein, the molar ratio of n-decyl aldehyde, epoxybromobutane and pyrimidine is 1:1.2:0.9.

[0029] (2) Degreaser A 1 The preparation method is as follows:

[0030] ①Add 1 mol of n-decylaldehyde to a three-necked flask equipped with an electric stirrer, reflux condenser and thermometer, then add 1872g of carbon tetrachloride, heat up to 30°C, stir for 10min at a stirring rate of 300rpm, then add 0.078g The mass concentration is 30% boron trifluoride ethyl ether solution, 1.2mol of epoxybromobutane is placed in the constant pressure dropping fun...

Embodiment 2

[0033] Embodiment 2: Degreaser A 2 and its preparation method

[0034] (1) Degreaser A 2 The composition and components are as follows:

[0035] Degreaser A 2 It is an intermediate formed by the reaction of n-decyl aldehyde with bromobutylene epoxy under the catalysis of boron trifluoride ether solution, and then reacted with pyrimidine to form a cationic degreasing agent. Its molecular formula is as follows:

[0036]

[0037] Wherein, the molar ratio of n-decyl aldehyde, epoxybromobutane and pyrimidine is 1:0.75:0.5.

[0038] (2) Degreaser A 2 The preparation method is as follows:

[0039] ① Add 1 mol of n-decyl aldehyde to a three-necked flask equipped with an electric stirrer, a reflux condenser and a thermometer, then add 1560 g of acetonitrile, heat up to 32 ° C, stir at a stirring rate of 350 rpm for 25 min, and then add 0.10 g of 30% boron trifluoride ether solution, put 0.75mol epoxybromobutane in a constant pressure dropping funnel, control the dropping rate ...

Embodiment 3

[0042] Embodiment 3: Degreaser A 3 and its preparation method

[0043] (1) Degreaser A 3 The composition and components are as follows:

[0044] Degreaser A 3 It is an intermediate formed by the reaction of n-decyl aldehyde with bromobutylene epoxy under the catalysis of boron trifluoride ether solution, and then reacted with pyrimidine to form a cationic degreasing agent. Its molecular formula is as follows:

[0045]

[0046] Wherein, the molar ratio of n-decyl aldehyde, epoxybromobutane and pyrimidine is 1:1.5:2.

[0047] (2) Degreaser A 3 The preparation method is as follows:

[0048] ①Add 1 mol of n-decyl aldehyde to a three-necked flask equipped with an electric stirrer, reflux condenser and thermometer, then add 2340g of carbon tetrachloride, heat up to 35°C, stir for 30min at a stirring rate of 400rpm, then add 0.156g The mass concentration is 30% boron trifluoride ether solution, 1.5mol of epoxybromobutane is placed in the constant pressure dropping funnel, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com