A treatment system and process for industrial sewage containing heavy metals

A technology for treating process and industrial sewage, applied in water/sewage treatment, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc. Achieve the effect of improving the sewage treatment process and changing the poor targeting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described below.

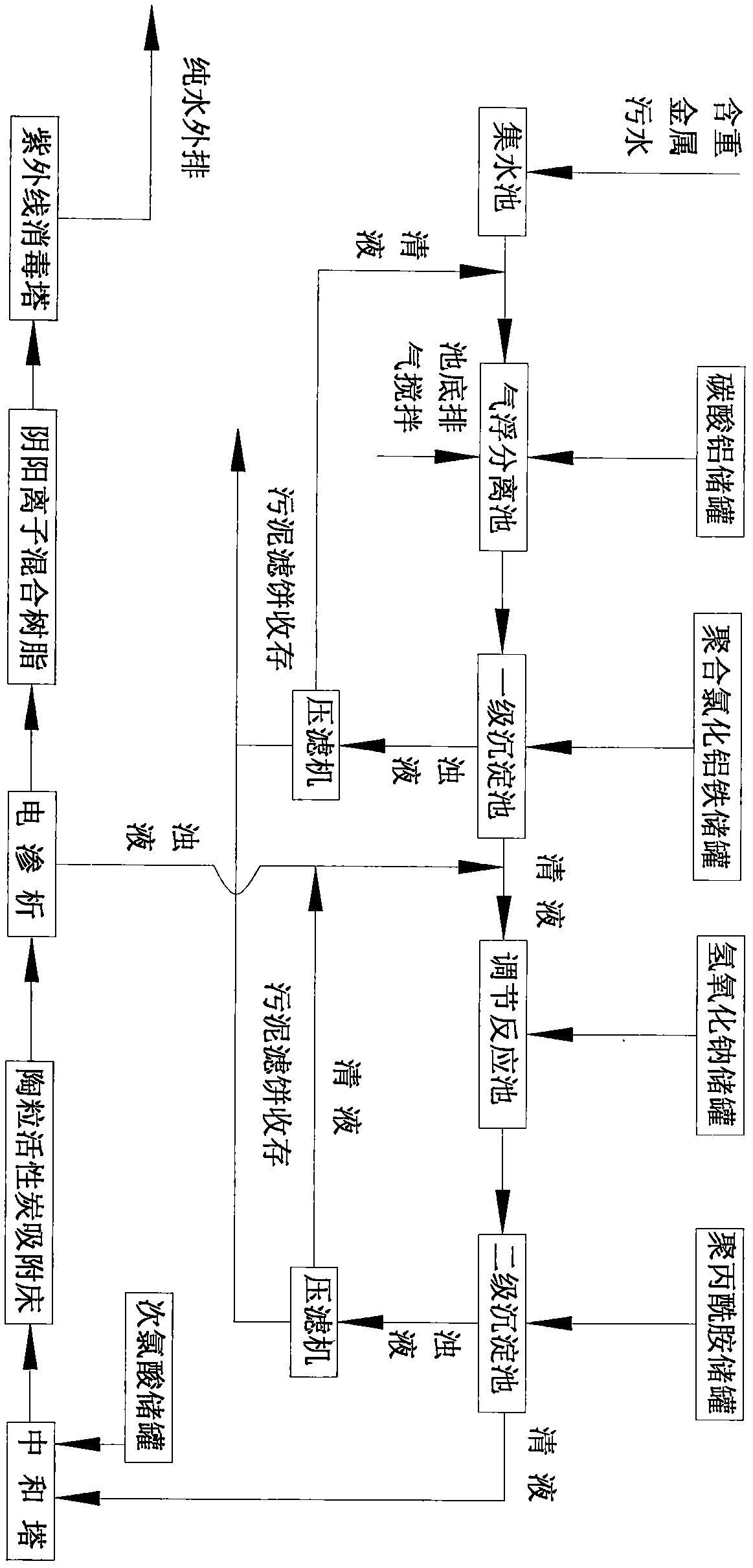

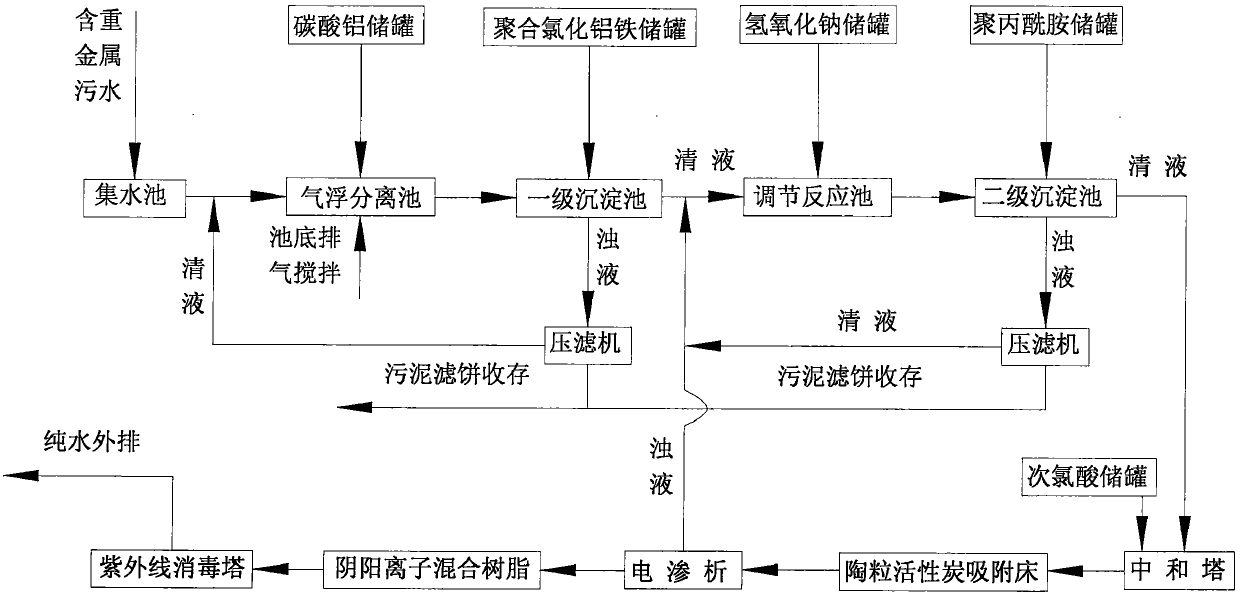

[0033] Such as figure 1 As shown, a treatment system for industrial sewage containing heavy metals. The treatment system includes a reaction system, a post-filtration system, a filter press, and a chemical storage tank. The reaction system is an air flotation separation tank, a first-stage sedimentation tank, and a regulating reaction tank. , Two-stage sedimentation tank and neutralization tower, the later filtration system is ceramsite activated carbon adsorption bed, electrodialysis, anion and cation mixed resin, and ultraviolet disinfection tower. There are two filter presses connected to the first-stage sedimentation tank and On one side of the secondary sedimentation tank, chemical storage tanks include aluminum carbonate storage tanks, polyaluminum ferric chloride storage tanks, sodium hydroxide storage tanks, polyacrylamide storage tanks and hypochlorous acid storage tanks. The aluminum carbonate s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com