Selective composite photo-catalyst powder and preparation method and application thereof

A photocatalyst, composite light technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problems of slow cooling speed, long sintering cycle, time-consuming and laborious, etc. Uniform, low cost, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

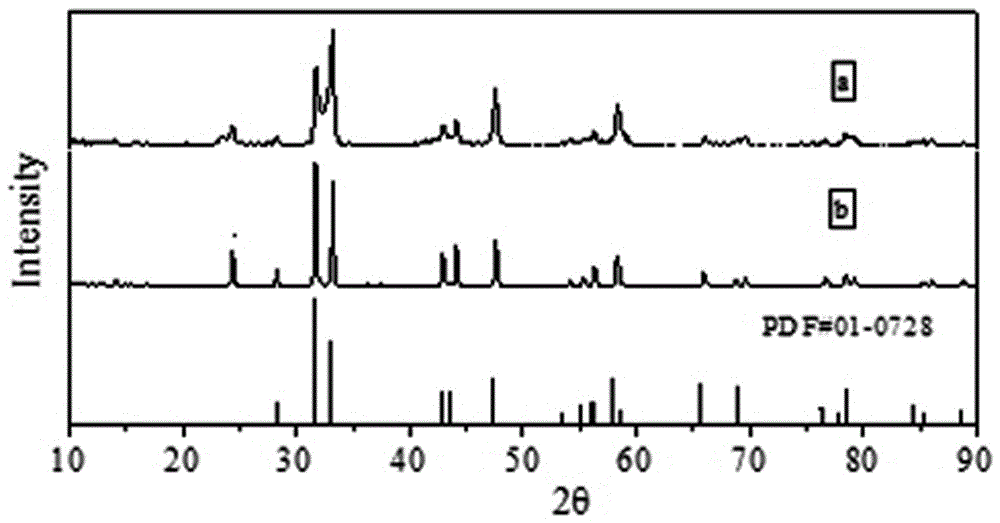

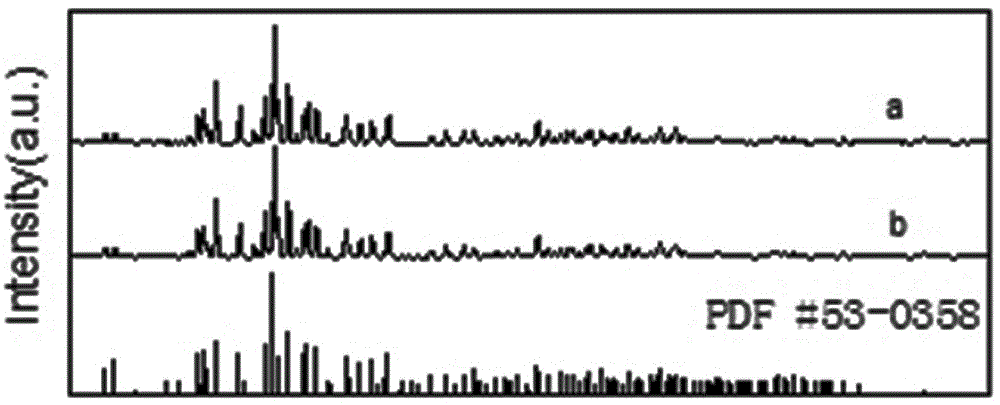

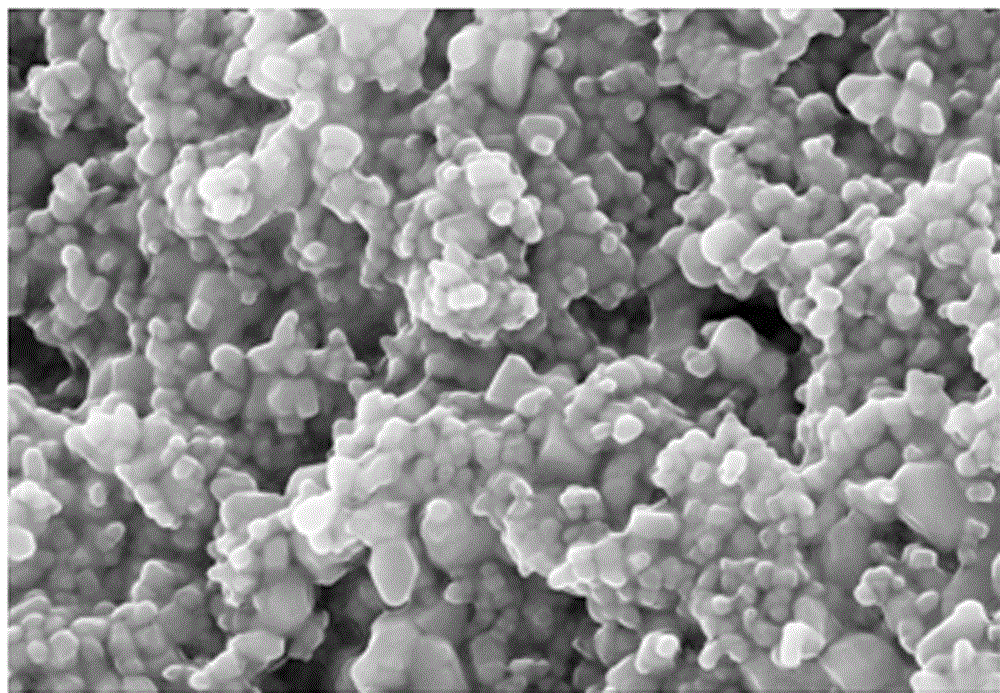

[0033] Preparation of Novel Selective Composite Photocatalyst Powder La by Impregnation Method 2 NiO 4 / Y 2 Mo 4 o 15 , comprising the following steps: Weigh 1mmol nickel acetate and 2mmol lanthanum acetate, dissolve them in 60ml distilled water to obtain solution A; slowly add a sodium hydroxide solution with a concentration of 1 / 300mol L-1 in solution A, and adjust the pH value of the solution to 10, stirred for 1 hour, and the rotation speed was 500r / min, and then the solution was suction-filtered to obtain precipitate B; the precipitate B was calcined in a muffle furnace at 800°C and kept for 1 hour to obtain catalyst powder C; into 30ml of absolute ethanol, high-speed ball milling, ball mill rotation speed 2000r / min, ball milling 2h, drying temperature 40°C, time 90min, to obtain powder D; weigh 1mmol yttrium acetate, weigh 2mmol ammonium molybdate, Dissolve in 60ml of distilled water to obtain solution E; mix solution E with powder D, put it in an oven at 60°C, dry i...

Embodiment 2

[0035] Preparation of Novel Selective Composite Photocatalyst Powder La by Impregnation Method 2 NiO 4 / Y 2Mo 4 o 15 , including the following steps: Weigh 2mmol nickel acetate and 4mmol lanthanum acetate, dissolve them in 120ml distilled water to obtain solution A; slowly add a sodium hydroxide solution with a concentration of 1 / 300mol L-1 in solution A, and stir for 1.5h , the rotation speed was 800r / min, and then the solution was suction filtered to obtain precipitate B; the precipitate B was calcined in a muffle furnace at 900°C and kept for 1.5h to obtain catalyst powder C; put powder C into 40ml of anhydrous In ethanol, high-speed ball milling, ball mill rotation speed 4000r / min, ball milling 4h, drying temperature 90°C, time 30min, to obtain powder D; weigh 1mmol yttrium nitrate, 2mmol ammonium molybdate, dissolve in 60ml of distilled water to obtain solution E; mix solution E with powder D, put it in an oven at 70°C, dry it for 1.5h, grind it, put it into a muffle ...

Embodiment 3

[0037] Preparation of Novel Selective Composite Photocatalyst Powder La by Impregnation Method 2 NiO 4 / Y 2 Mo 4 o 15 , comprising the following steps: take 2mmol nickel acetate and 4mmol lanthanum nitrate, dissolve them in 120ml distilled water to obtain solution A; slowly add a sodium hydroxide solution with a concentration of 1 / 400mol L-1 in solution A, and adjust the pH value 9.5, stirred for 2 hours, and the rotation speed was 700r / min, and then the solution was suction-filtered to obtain precipitate B; the precipitate B was calcined in a muffle furnace at 850°C and kept for 2 hours to obtain catalyst powder C; into 30ml methanol, high-speed ball milling, ball mill rotation speed 3000r / min, ball milling 4h, drying temperature 50°C, time 75min, to obtain powder D; weigh 2mmol yttrium nitrate, weigh 4mmol ammonium molybdate, dissolve in 120ml of distilled water to obtain solution E; mix solution E with powder D, put it in an oven at 70°C, dry it for 1.5h, grind it, put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com