Dimethyl sulfide-containing tail gas absorption apparatus and dimethyl sulfide-containing tail gas absorption method

A technology for absorbing dimethyl sulfide and tail gas, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of high odor in laboratories or production areas, restrictions on the application of borane dimethyl sulfide, and excessive discharge of tail gas and other problems, to achieve good degradation effect, promote application, and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

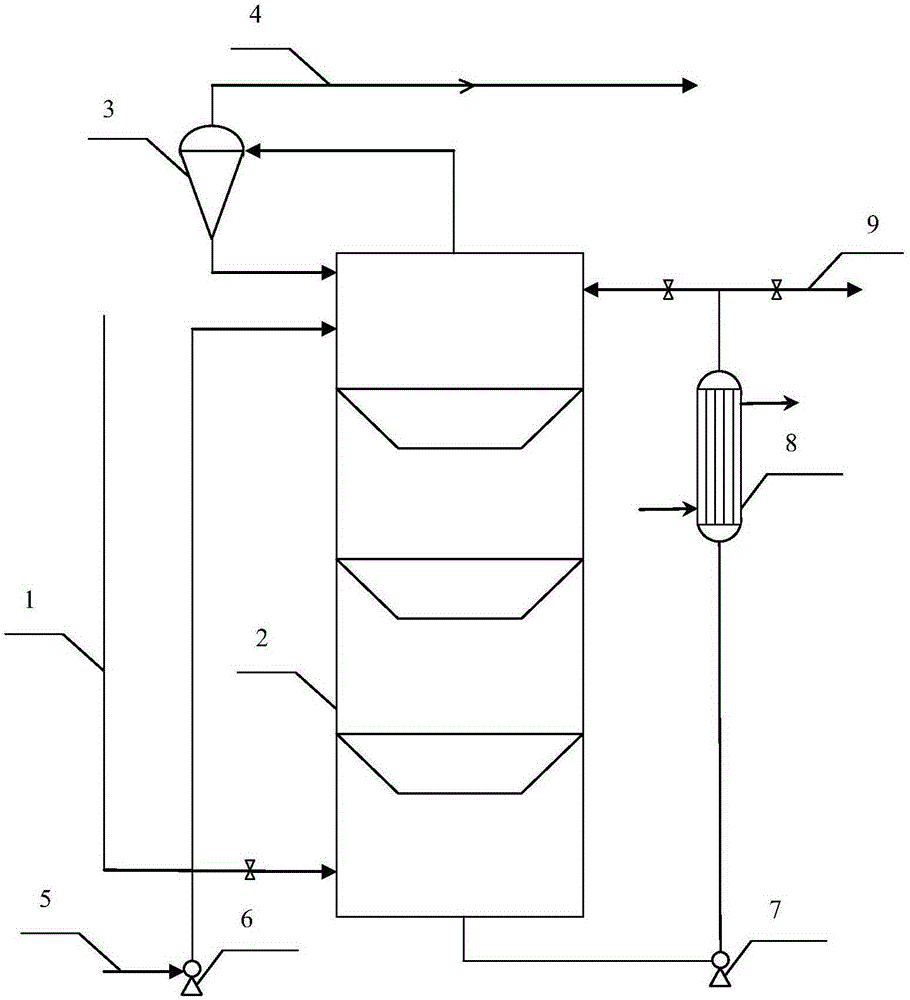

[0038] Such as figure 1 As shown, the present invention discloses a tail gas absorption device containing dimethyl sulfide, including: dimethyl sulfide tail gas pipe 1, pickling tower 2, gas-liquid separator 3, exhaust pipe 4, degradation oxidant input pipe 5 , feed pump 6, circulating pump 7, condenser 8; dimethyl sulfide tail gas pipe 1, degradation oxidant input pipe 5 and exhaust pipe 4 are connected with pickling tower 2 respectively, and between exhaust pipe 4 and pickling tower 2 A gas-liquid separator 3 is provided between them; the degradation oxidant passed into by the degradation oxidant input pipe 5 passes into the pickling tower 2 through the feed pump 6; The condenser 8 cools down and then passes into the pickling tower 2 for recycling, and the spent degradation oxidant is discharged through the waste liquid discharge pipe 9 connected with the condenser 8 .

[0039] The specific absorption method is: the tail gas containing dimethyl sulfide produced in the proce...

Embodiment 2

[0041] In the production process of catechol borane, borane dimethyl sulfide is used as reducing agent, and hydrogen gas is generated at the same time during the reaction process, and hydrogen gas is mixed with dimethyl sulfide vapor to form tail gas. The tail gas is detected before treatment, and the dynamic content of dimethyl sulfide is 0.1 kg / m 3 ~0.3kg / m 3 , exhaust flow rate 0.8m 3 / h. The above-mentioned tail gas containing dimethyl sulfide is passed into a stirred reactor, 2% to 10% calcium hypochlorite aqueous solution is used as a degradation oxidant, the vent pipe is passed below the liquid level, and the temperature is lowered through a cooling medium, containing dimethyl sulfide After the tail gas is absorbed by the degradation oxidant (the weight ratio of the degradation oxidant to the tail gas containing dimethyl sulfide is 10:1, and the reaction temperature is 25°C to 35°C), it is discharged through the exhaust pipe. The gas discharged through the exhaust pi...

Embodiment 3

[0043] In the production process of catechol borane, borane dimethyl sulfide is used as a reducing agent. During the reaction, hydrogen gas is generated at the same time. The hydrogen gas is mixed with dimethyl sulfide vapor to form tail gas. The tail gas is detected before treatment. The dynamic content of dimethyl sulfide is 0.1 kg / m 3 ~0.3kg / m 3 , exhaust flow rate 0.8m 3 / h. The tail gas containing dimethyl sulfide is passed into the storage tank, the hydrogen peroxide aqueous solution is used as a degradation oxidant, the vent pipe is passed below the liquid level, and the temperature is lowered through the cooling medium, and the tail gas containing dimethyl sulfide is absorbed by the degradation oxidant (the degradation oxidant The weight ratio to tail gas containing dimethyl sulfide is 5:1, and the reaction temperature is 15°C to 25°C), and it is discharged through the exhaust pipe. The gas discharged through the exhaust pipe has been tested to have a dimethyl sulfid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com