Composite electrode for electro-kinetic remediation of heavy metal contaminated soil, electro-kinetic remediating device and electro-kinetic remediation method

A composite electrode and electrodynamic restoration technology, which is applied in the restoration of polluted soil, etc., can solve the problems of easy shedding of active materials, affecting the removal efficiency of pollutants, and the stability of current, so as to shorten the restoration period, shorten the restoration cost, and realize The effect of in situ removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

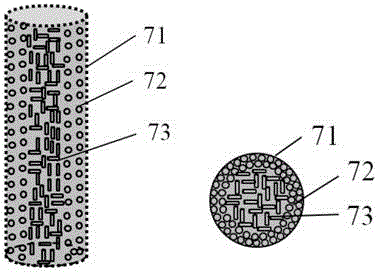

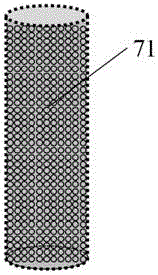

[0042] Example 1. Preparation of a composite electrode for electrokinetic restoration of heavy metal-contaminated soil

[0043] (1) Preparation of modified sepiolite: the particle size of the modified sepiolite obtained by acid treatment modification, heat treatment modification and silane coupling agent modification is 20-100 mesh.

[0044] Acid treatment modification:

[0045] Use 1mol / L HCl to modify the sepiolite, and the solid-to-liquid ratio is 1:10 (if the sepiolite is 10g, HCl is 100ml). Shake in a constant temperature oscillator at a temperature of 50°C for 6 hours, centrifuge in a centrifuge at a speed of 4000r / min for 10 minutes to separate water and sepiolite, add deionized water to wash, centrifuge, and repeat washing and centrifugation for 3 to 5 times until The pH is around 6. After centrifugation, place in a desiccator at a temperature of 50°C to dry.

[0046] Heat treatment modification: the acid-modified sepiolite was calcined at 450°C for 4 hours, and the...

Embodiment 2

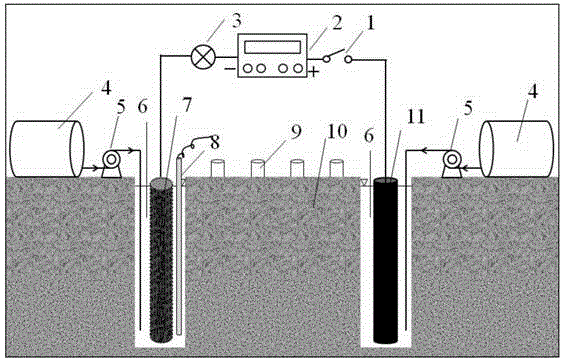

[0052] Example 2. Preparation of an electric repair device for heavy metal-contaminated soil (1) Preparation of electrolyte: this part belongs to the prior art, such as with 0.2mol / L of HNO 3 as an electrolyte.

[0053] The specific preparation steps are as follows: add concentrated nitric acid to a certain amount of water to prepare 0.2mol / L HNO 3 .

[0054] (2) Add electrolyte to the electrolytic cell, connect the composite electrode, graphite electrode, DC power supply, switch and other components of the device with wires, connect the power supply, and set the flow rate of the extraction pump to 0.01-0.05L / h.

[0055] (3) Deployment: Control the moisture content of the soil to be greater than 20%, the DC power supply voltage is 100V / m~600V / m, and the flow rate of the extraction pump is 0.01~0.05L / h to ensure efficient and stable operation of the device.

Embodiment 3

[0056] Embodiment 3. Use the composite electrode of embodiment 1 and the electrodynamic restoration device of embodiment 2 to remediate heavy metal polluted soil

[0057] The specific operation steps are as follows:

[0058] The prepared composite electrode is inserted into the electrolytic cell, the electrolyte is passed into the electrolytic cell, the circuit is connected to the composite electrode, graphite electrode, switch, and ammeter, the extraction pump is turned on, and then repaired.

[0059] Regularly monitor the changes in the concentration of heavy metals in the electrolytic cell and monitoring points, and record the pH and conductivity changes of the anode and catholyte in real time, and replace the composite electrode material when the conductivity exceeds a certain value.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com