Preparation method of rosin derivative modified polyacrylamide hydrophilic gel

A technology of polyacrylamide and rosin derivatives, which is applied in the field of hydrogel, can solve the problems that limit the research and development of hydrogel, and achieve the effect of low cost, low swelling rate and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

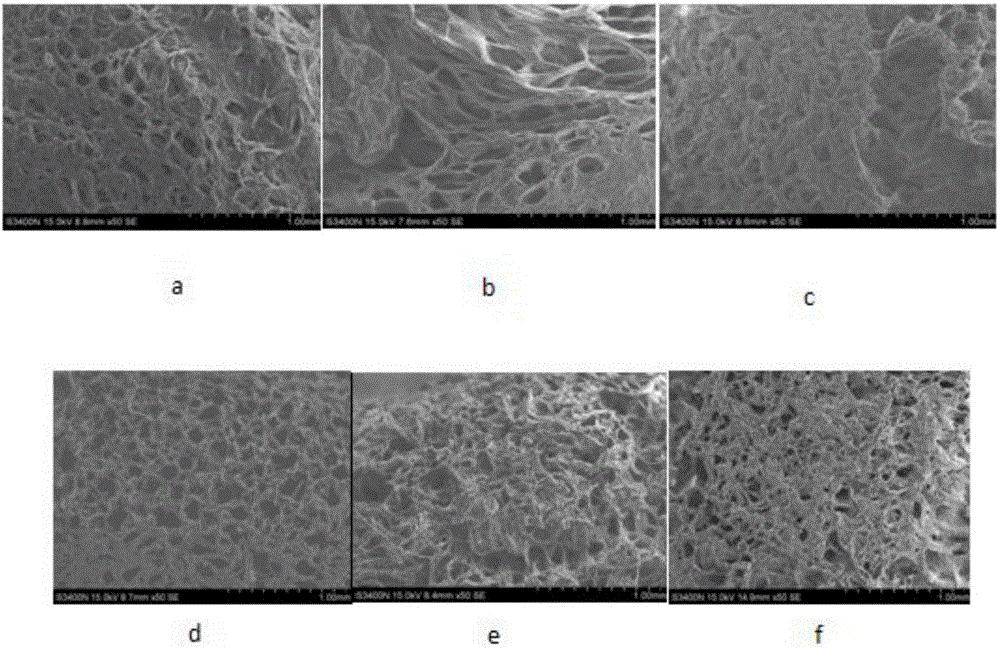

Image

Examples

Embodiment 1

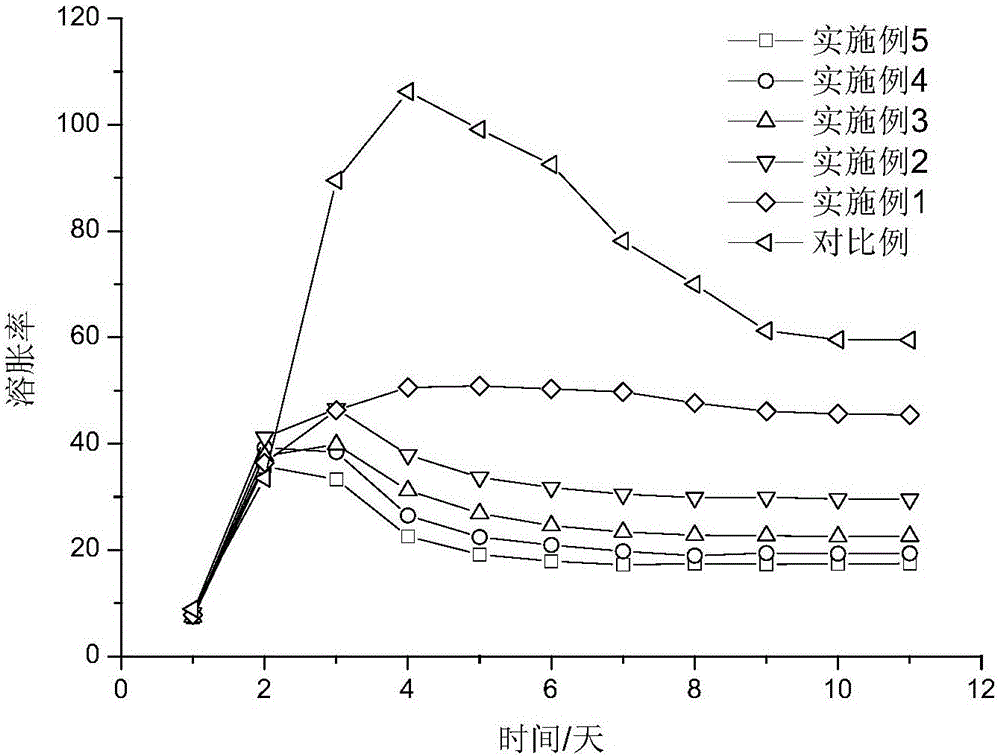

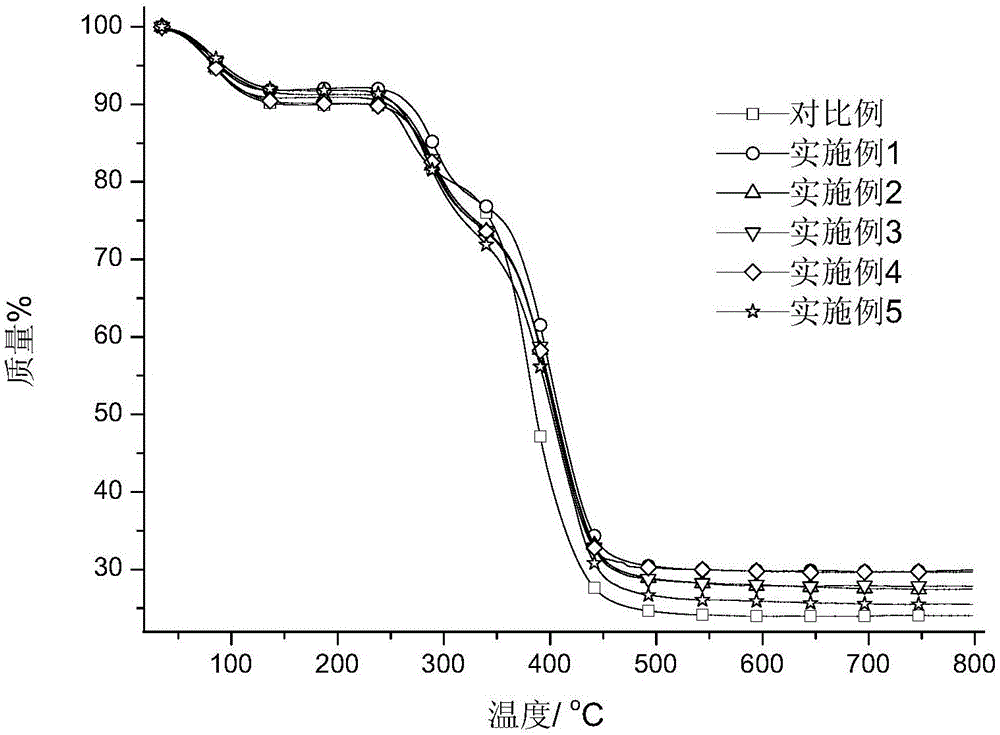

[0028] Weigh 8.3g of fumapimaric acid, 7.62g of oxalyl chloride, and 30mL of tetrahydrofuran, react at room temperature for 4h, then add polyethylene glycol 200 12g, react at 40°C for 12h, and spin evaporate to obtain polyethylene glycol fumapimaric acid 200 esters. Polyethylene glycol 200 fumapimaric acid was dissolved in 30 mL of tetrahydrofuran, and 7.62 g of acryloyl chloride was added dropwise at room temperature, and reacted for 4 hours to obtain a free-radical polymerizable rosin-based derivative. Weigh 1g of acrylamide, 0.15g of free radical polymerizable rosin derivative and dissolve in 8.85g of 7% sodium lauryl sulfate aqueous solution, add 0.008g of ammonium persulfate, 25μL N,N,N', N'-tetramethylethylenediamine was reacted at 45° C. for 24 hours to obtain rosin derivative-modified polyacrylamide hydrogel. The swelling rate is 45.4 times, the tensile strain is 1500%, the compression rate is 96.4%, the initial decomposition temperature is 290.0°C, and the maximum de...

Embodiment 2

[0030] Weigh 1g of acrylamide, 0.20g of free-radical polymerizable rosin derivative (prepared by the method in Example 1) and dissolve in 8.8g of 7% sodium lauryl sulfate aqueous solution, add 0.008g of potassium persulfate, 0.01 g of sodium bisulfite was reacted at 40° C. for 24 hours to obtain rosin derivative-modified polyacrylamide hydrogel. The swelling rate is 29.5 times, the tensile strain is 800%, the compression rate is 93.2%, the initial decomposition temperature is 287.1°C, and the maximum decomposition temperature is 401.5°C.

Embodiment 3

[0032] Weigh 1g of acrylamide, 0.25g of free-radical polymerizable rosin derivative (prepared by the method in Example 1) and dissolve in 8.75g of 10% sodium lauryl sulfate aqueous solution, add 0.008g of ammonium persulfate, 25 μL of N,N,N',N'-tetramethylethylenediamine was reacted at 40°C for 24 hours to obtain rosin derivative-modified polyacrylamide hydrogel. The swelling rate is 22 times, the tensile strain is 600%, the compression rate is 95%, the initial decomposition temperature is 288.4°C, and the maximum decomposition temperature is 405.9°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial decomposition temperature | aaaaa | aaaaa |

| Maximum decomposition temperature | aaaaa | aaaaa |

| Initial decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com