Method for synthesizing tantalum-based nitride (nitrogen oxide) nanoparticles, and nanoparticles thereof

A nanoparticle, tantalum-based nitrogen technology, applied in the field of nanomaterials, can solve the problems of difficult raw materials, difficult to achieve industrialization, long reaction time, etc., achieve product quality and high yield, good application and industrialization prospects, and breakthrough safety. Effects of pitfalls and limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

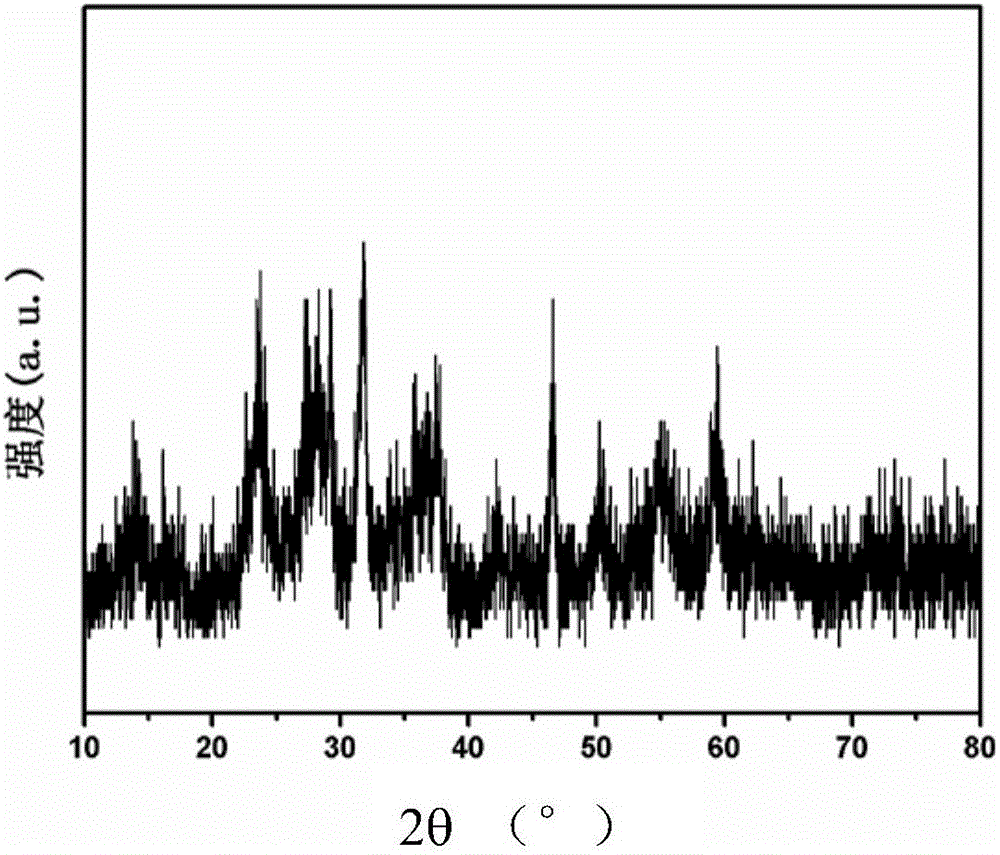

[0043] 0.25g TaCl 5 (0.7mM) was dissolved in 2mL of methanol, then 0.103g of strontium chloride (0.65mM) was added, after dissolution, 0.084g of urea (1.4mM) was added, and stirred at room temperature for 4h to gel. It was roasted at 700° C. for 5 h in a nitrogen flow, and the obtained product was treated with 1 mol / L hydrochloric acid and stirred at room temperature for 48 h. The obtained product was washed several times with ethanol, filtered with suction, and dried at 50°C. Tantalum oxynitride nanoparticles A (TaON) were obtained.

Embodiment 2

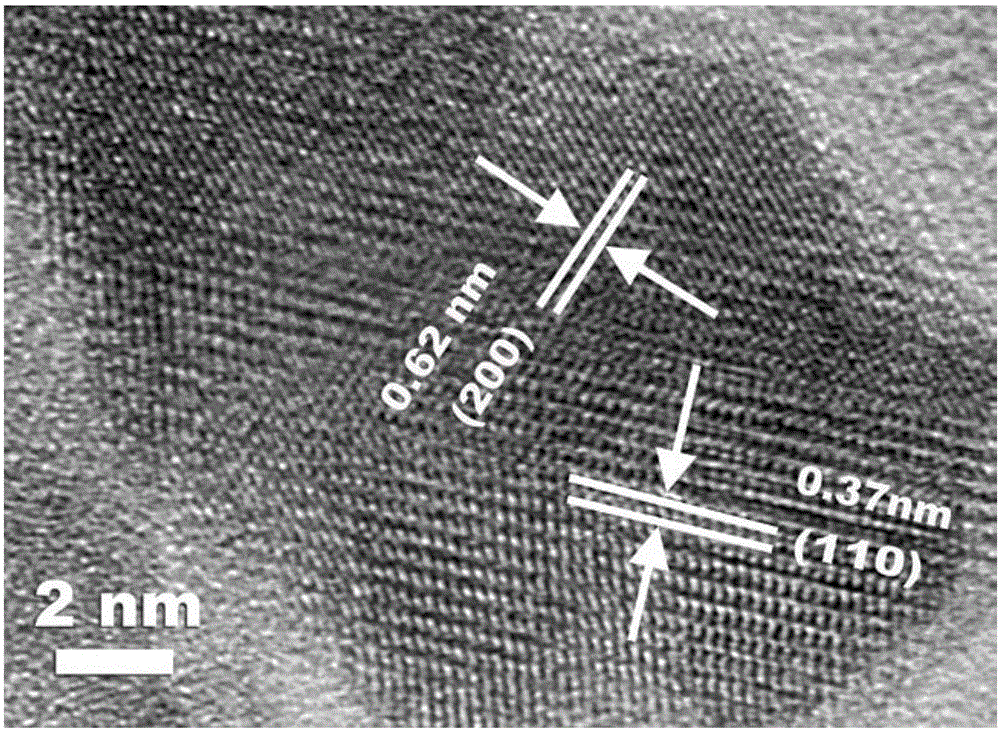

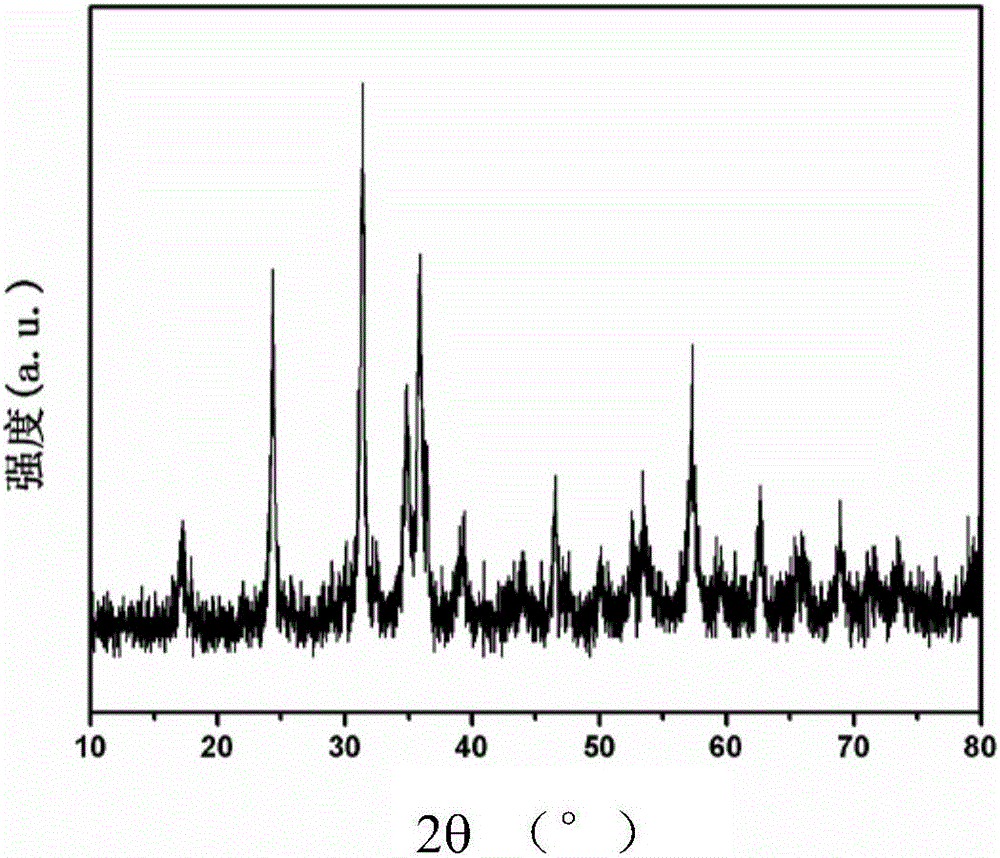

[0045] 0.25g TaCl 5 (0.7mM) was dissolved in 2mL of methanol, then 0.103g of strontium chloride (0.65mM) was added, and after dissolution, 0.294g of urea (4.9mM) was added, and stirred at room temperature for 4h to gel. It was roasted at 700° C. for 5 h in a nitrogen flow, and the obtained product was treated with 1 mol / L hydrochloric acid and stirred at room temperature for 48 h. The obtained product was washed several times with ethanol, filtered with suction, and dried at 50°C. Obtain tantalum pentanitride nanoparticles B (Ta 3 N 5 ).

Embodiment 3

[0047] 0.25g TaCl 5 (0.7mM) was dissolved in 2mL of methanol, then 0.103g of strontium chloride (0.65mM) was added, after dissolution, 0.084g of urea (1.4mM) was added, and stirred at room temperature for 4h to gel. It was calcined at 700° C. for 5 h in an argon flow, and the obtained product was treated with 1 mol / L hydrochloric acid and stirred at room temperature for 48 h. The obtained product was washed several times with ethanol, filtered with suction, and dried at 50°C. Tantalum oxynitride nanoparticles C(TaON) were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com