Special catalyst for removing hydrogen sulfide through selective catalytic oxidation and preparation method for special catalyst

A catalytic oxidation and catalyst technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. standards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

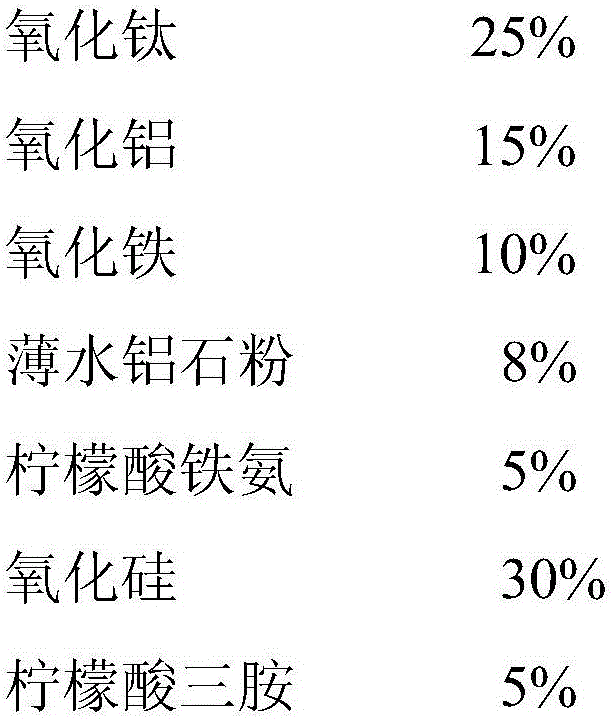

Embodiment 1

[0036] Mix 25g of titanium oxide, 15g of aluminum oxide, 10g of iron oxide, 8g of boehmite powder, 5g of ferric ammonium citrate, 30g of silicon oxide, 5g of triamine citrate, 1g of sodium aluminate and 1g of aluminum sulfate in a mixer for 15 minutes. get the mixture;

[0037] Add 20g of water to the above mixture and stir for 5 hours, then let it stand for 1 hour to fully oxidize, and then put it into an extruder at a constant temperature of 80°C and extrude it to obtain a molded product;

[0038] After drying the obtained molded product, put it into a roasting furnace for roasting at 800°C for 1 hour, and obtain the special catalyst DXY-1 for selective catalytic oxidation removal of hydrogen sulfide after cooling down.

Embodiment 2

[0040] Mix 25g of titanium oxide, 15g of aluminum oxide, 10g of iron oxide, 8g of boehmite powder, 5g of ferric ammonium citrate, 30g of silicon oxide, 5g of triamine citrate, 1g of sodium aluminate and 1g of aluminum sulfate in a mixer for 10 minutes, get the mixture;

[0041] Add 20g of water to the above mixture and stir for 4 hours, then let it stand for 1 hour to fully oxidize, then put it into an extruder at a constant temperature of 75°C and extrude it to obtain a molded product;

[0042] After drying the obtained molded product, put it into a roasting furnace for roasting at 750°C for 1 hour, and obtain the special catalyst DXY-1 for selective catalytic oxidation removal of hydrogen sulfide after cooling down.

Embodiment 3

[0044] Mix 25g of titanium oxide, 15g of aluminum oxide, 10g of iron oxide, 8g of boehmite powder, 5g of ferric ammonium citrate, 30g of silicon oxide, 5g of triamine citrate, 1g of sodium aluminate and 1g of aluminum sulfate in a mixer for 20 minutes. get the mixture;

[0045] Add 20g of water to the above mixture and stir for 6 hours, then let it stand for 40 minutes to fully oxidize, and then put it into an extruder at a constant temperature of 85°C and extrude it to obtain a molded product;

[0046] After drying the obtained molded product, put it into a roasting furnace for roasting at 850°C for 40 minutes, and obtain the special catalyst DXY-1 for selective catalytic oxidation removal of hydrogen sulfide after cooling down.

[0047] Performance Evaluation of Catalyst DXY-1 in Sour Gas Environment

[0048] Oxidative removal of hydrogen sulfide reaction is carried out in the reformer (special equipment independently developed by Dongshi - isothermal conversion plus DCS cold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com