Microcapsule, self-healing electrophoretic coating containing microcapsule and preparation method of microcapsule

A technology for electrophoretic coatings and microcapsules, applied in electrophoretic coatings, microcapsule preparations, microsphere preparation, etc., can solve the problems of micro-cracks in the paint film, internal damage, and reduce the protection function of the coating, and achieve small particle size and good stability. , Improve the effect of overall anti-corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

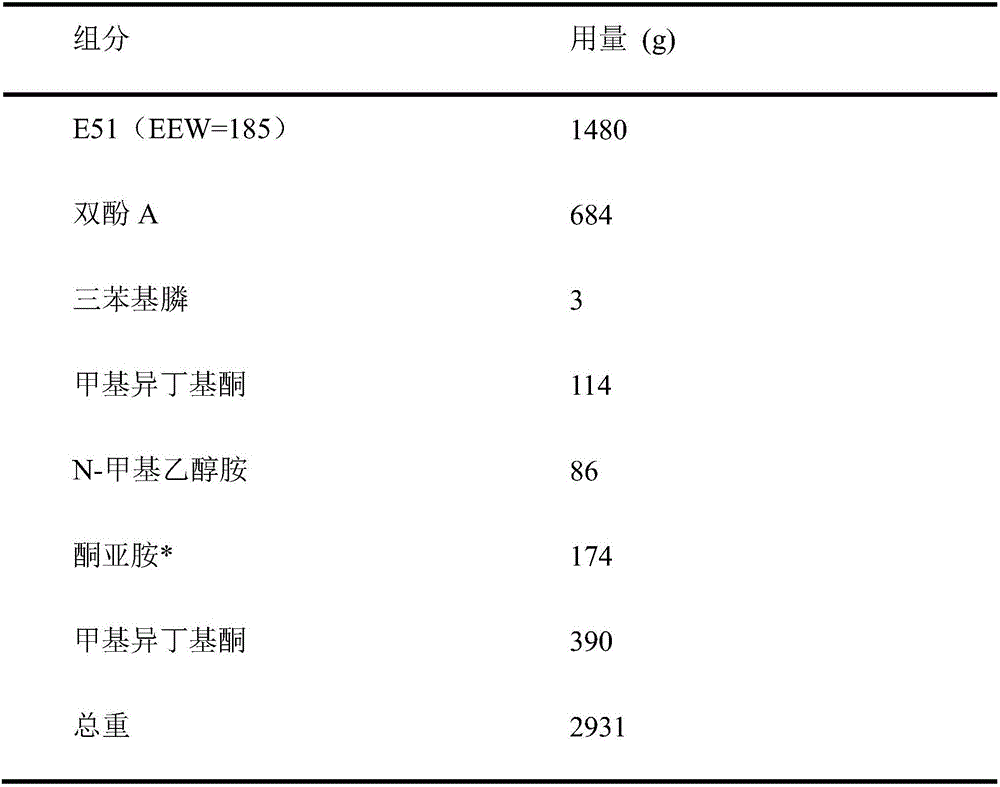

[0032] The preparation of embodiment 1 host resin

[0033]

[0034] * Prepared by the reaction of diethylenetriamine and methyl isobutyl ketone in a molar ratio of 1:2, the solid content of the final product is: 73%

[0035] In the reaction bottle equipped with a thermometer, a stirrer and a reflux condenser, add the E51 epoxy resin, bisphenol A and the first part of methyl isobutyl ketone in the prescribed amount in sequence. After the feeding is complete, start stirring and heat the reaction system to 120°C and keep it warm, add triphenylphosphine and raise the temperature to 150°C, and continue the reaction at this temperature for 1h. When the epoxy equivalent of the reaction system reaches the theoretical value (EEW =1140.5), began to cool down; when the system temperature dropped below 100°C, N-methylethanolamine and ketimine, the second part of methyl isobutyl ketone were added to the reaction system, and the temperature was raised to 120°C again, The reaction was co...

Embodiment 2

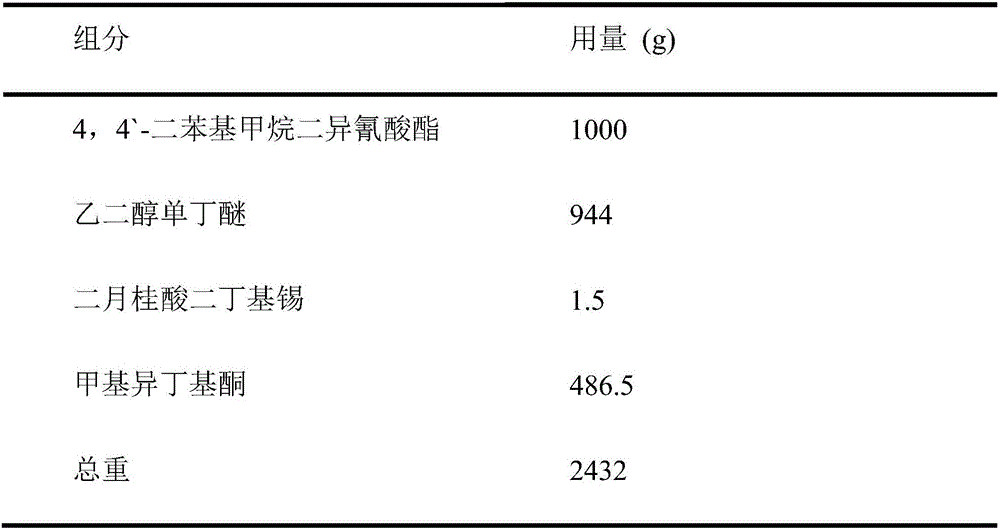

[0036] The preparation of embodiment 2 curing agent

[0037]

[0038] Add the formulated amount of 4,4`-diphenylmethane diisocyanate and dibutyltin dilaurate into the reaction flask equipped with a thermometer, stirrer and reflux condenser, stir and heat up to 60°C and start to add ethylene glycol mono For butyl ether, cool down with a water bath during the dropwise addition and control the temperature not to exceed 65°C. After the dropwise addition, continue to react at 80°C for 2 hours, and use the standard di-n-butylamine back titration method to analyze the remaining isocyanate group content in the reaction system. When the remaining isocyanate content is less than 0.2%, methyl isobutyl ketone is added for dilution to obtain a fully blocked isocyanate crosslinking agent with a final solid content of 80%.

Embodiment 3

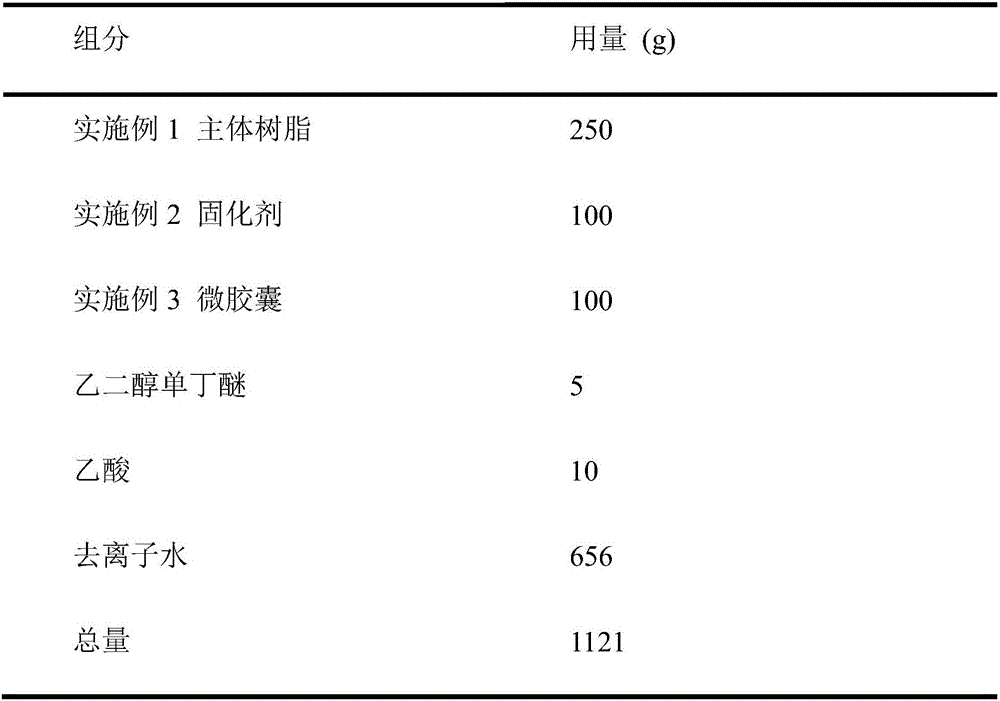

[0039] The preparation of embodiment 3 microcapsules

[0040] In the four-necked flask equipped with thermometer, stirrer and reflux condenser, add E51 epoxy resin (EEW=185) 296g, bisphenol A106g, methyl isobutyl ketone 45g, triphenylphosphine 0.6g successively, heat up After 145-155°C, keep it warm for 2 hours. After measuring the epoxy equivalent of 670, add 126g of silane coupling agent KH-550, 86g of methyl isobutyl ketone, react for 2 hours, the reaction temperature is 120-125°C, then vacuum dry and dry Keep airtight. Add 30g of urea and 150g of 37% formaldehyde into a four-neck flask, stir and mix thoroughly, then adjust the pH value to 8.0-9.0 with triethanolamine, and raise the temperature to 70°C until completely dissolved to obtain a colorless and transparent prepolymer. Then cool down to room temperature, add ammonium chloride 3g, resorcinol 4g, sodium chloride 3.5g and OP-10 emulsifier 1.3g in the prepolymer, after stirring and dissolving completely, adjust the pH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com