Preparation method of polyaniline-graphene hollow microspheres

A technology of hollow microspheres and graphene, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as the gap in theoretical specific surface area, and achieve the effects of improved electrochemical performance, mild reaction conditions, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

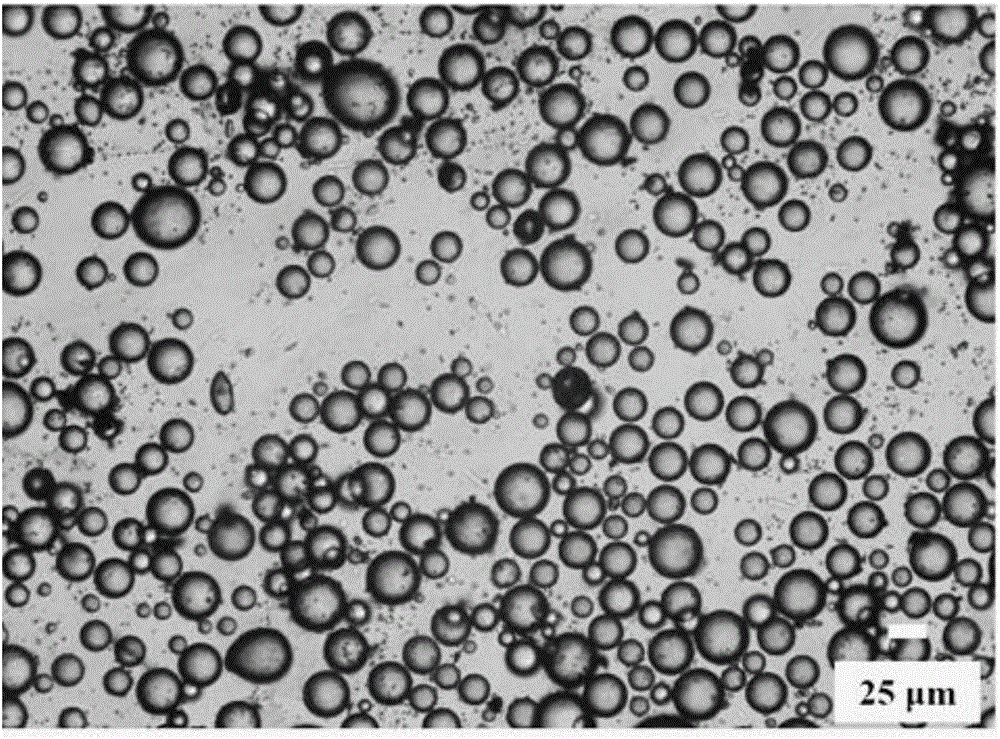

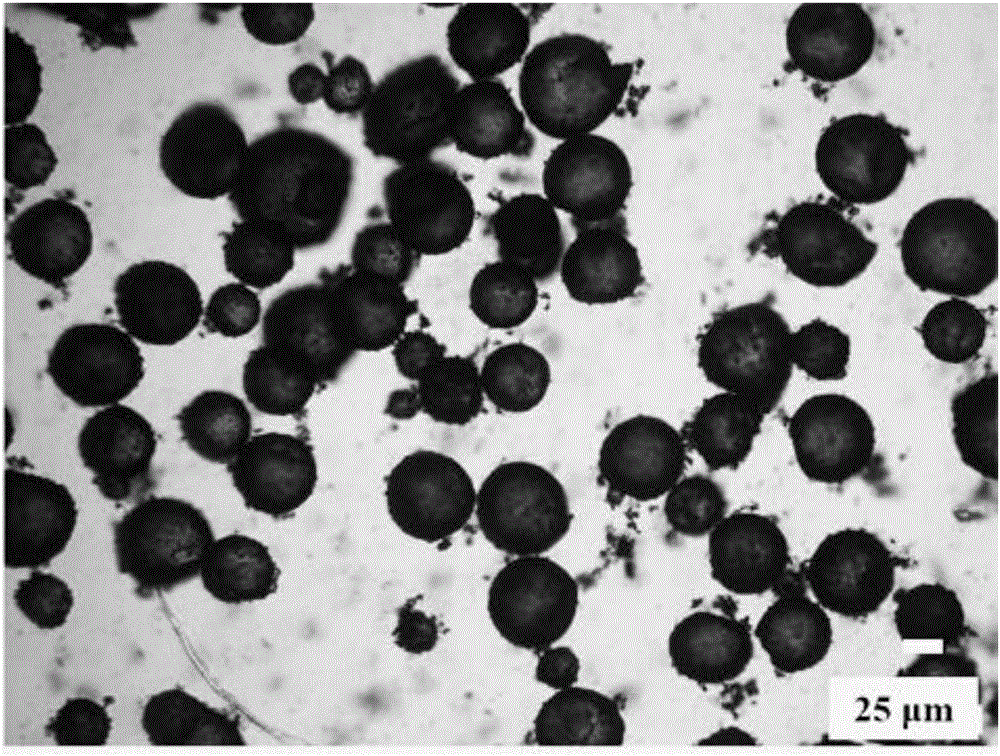

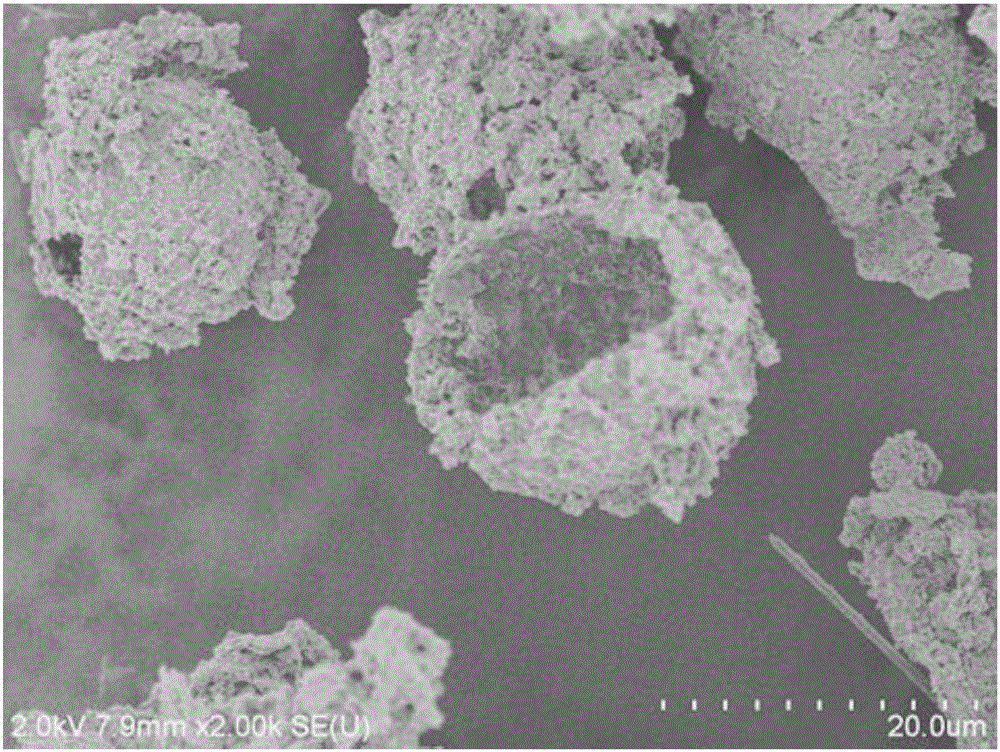

[0030] Disperse 90 mg of graphene oxide in 20 mL of water by ultrasound, and use hydrazine hydrate as a reducing agent to reduce GO to graphene (RGO); disperse the freshly prepared RGO in 25 mL of water; add 227 mg of p-sulfanil to the RGO dispersion acid (SA) and 115 mg of isoamyl nitrite, stirred overnight at 80° C.; filtered, washed and dried to obtain sulfonic acid-modified graphene (GSA). Take 9 mg of the sulfonated graphene obtained above, add 3 mL of water, and ultrasonicate for 40 minutes at an ultrasonic power of 200 W as the water phase; add 3 mL of oil phase toluene (the oil phase contains 120 μL of aniline monomer), and use a homogenizer at 15000 rpm Emulsify for 2 minutes to obtain an oil-in-water (O / W) emulsion (see figure 1 ); place the prepared emulsion in a 0°C ice-water bath after standing for 18 hours, stir for 40 minutes, and the stirring speed is 300rpm; in addition, dissolve 285mg of ammonium persulfate in 1mol / L hydrochloric acid solution, and place in ...

Embodiment 2

[0035]60mg of graphene oxide was dispersed in 12mL of water by ultrasound, and GO was reduced to graphene (RGO) using hydrazine hydrate as a reducing agent; the newly prepared RGO was dispersed in 20mL of water; 45mg of sulfanil was added to the RGO dispersion acid (SA) and 27 mg of isoamyl nitrite, stirred overnight at 80° C.; filtered, washed and dried to obtain sulfonic acid-modified graphene (GSA). Take 15 mg of the sulfonated graphene obtained above, add 5 mL of water, and ultrasonicate for 60 minutes at an ultrasonic power of 400 W as the water phase; add 3 mL of oil phase toluene (the oil phase contains 24 μL of aniline monomer), and use a homogenizer at 8000 rpm Emulsify for 1 minute to obtain an oil-in-water (O / W) emulsion; place the prepared emulsion in an ice-water bath at 0°C after standing for 24 hours, and stir for 30 minutes at a stirring speed of 500 rpm; dissolve 23.5 mg of ammonium persulfate in 2mol / L hydrochloric acid solution, placed in 0°C ice-water bath ...

Embodiment 3

[0037] Disperse 90mg of graphene oxide in 20mL of water by ultrasound, and use hydrazine hydrate as a reducing agent to reduce GO to graphene (RGO); disperse the newly prepared RGO in 20mL of water; add 450mg of p-sulfanil to the RGO dispersion acid (SA) and 270mg of isoamyl nitrite, stirred overnight at 80°C; filtered, washed and dried to obtain sulfonic acid-modified graphene (GSA). Take 15 mg of the sulfonated graphene obtained above, add 10 mL of water, and ultrasonicate for 40 minutes at an ultrasonic power of 200 W as the water phase; add 5 mL of oil phase toluene (the oil phase contains 250 μL of aniline monomer), and use a homogenizer at 15000 rpm Emulsify for 2 minutes to obtain an oil-in-water (O / W) emulsion; place the prepared emulsion in an ice-water bath at 0°C after standing for 18 hours, and stir for 40 minutes at a stirring speed of 250 rpm; dissolve 85 mg of ammonium persulfate in 1.5 mol / L hydrochloric acid solution, placed in an ice-water bath at 0°C for 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com