TiO2 microspheres and preparation method of TiO2-based photoanode dye-sensitized solar cell

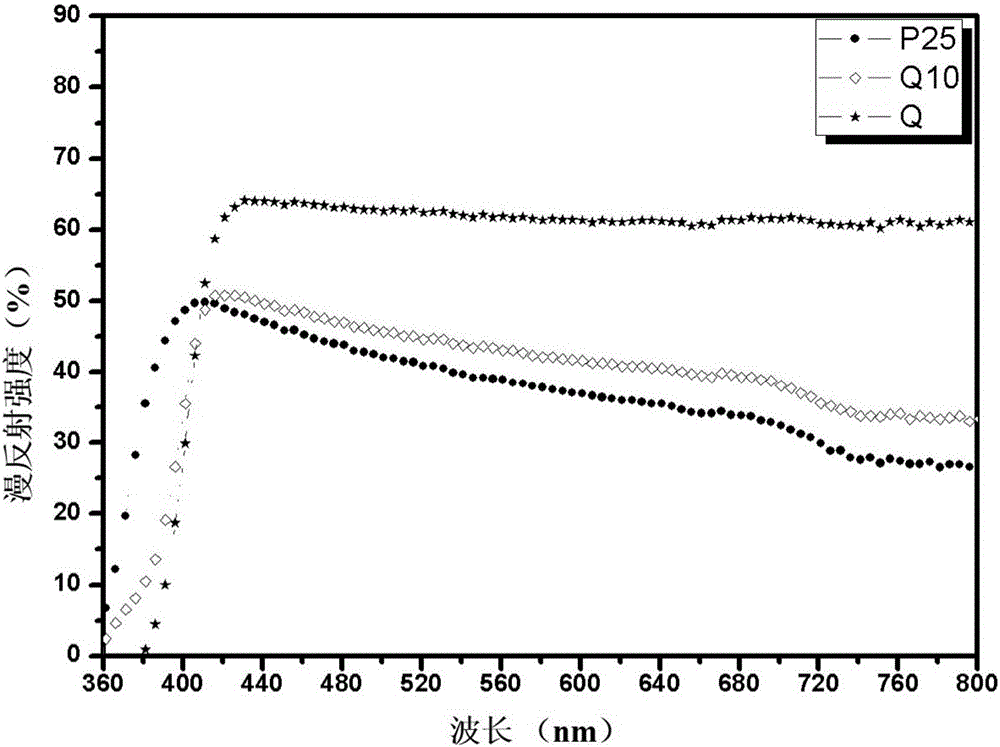

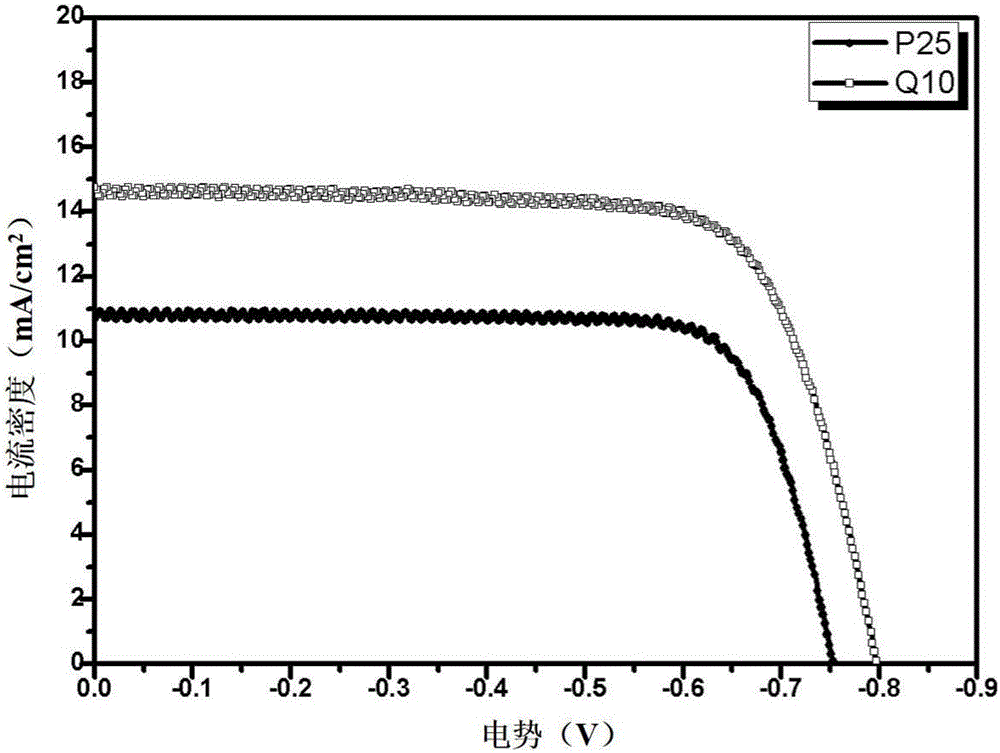

A technology of solar cells and dye sensitization, which is applied in the preparation of solar cells, the preparation of TiO2 microspheres and their TiO2-based photoanode dye-sensitized solar cells, and can solve the problems of difficulty in improving battery performance and low dye loading. Achieve the effects of improving battery performance, enhancing suppression of electron recombination, and good photoelectric conversion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

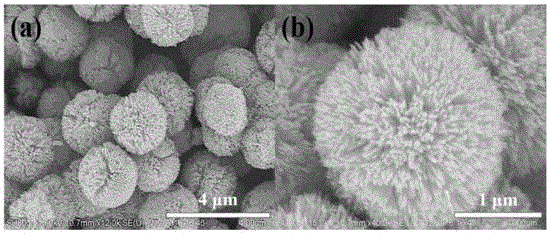

[0033] Nanorod self-assembled rutile phase TiO 2 Preparation of microspheres:

[0034] Take 5mL tetrabutyl titanate and 1.5mL concentrated hydrochloric acid in a 100mL beaker, stir at a stirring speed of 320r / min for 15min, take 1.00mL titanium tetrachloride solution with a concentration of 2mol / L with a pipette gun, and add it dropwise to the solution , to ensure no precipitation during the process, after stirring for 10 minutes, add 25mL of toluene and stir rapidly for 2h, move the mixture to a 50mL reactor and react at 150°C for 4h, wash with distilled water and ethanol for 2-3 times, centrifuge and dry for 24h , to obtain nanorod self-assembled rutile phase TiO 2 Microspheres.

Embodiment 2

[0036] Efficient TiO 2 Fabrication of photoanode dye-sensitized solar cells:

[0037] (1) Cleaning of photoanode FTO glass substrate and TiCl 4 Pre-processing:

[0038] The photoanodic FTO glass substrate was treated with detergent, deionized water, isopropanol, acetone and ultraviolet ozone for 15-120 minutes to obtain a clean surface. The cleaned FTO glass substrate was immersed in 0.04mol / L TiCl 4In the aqueous solution, stand at 70°C for 30 minutes, and wash with distilled water and ethanol for 1 or 2 times. For the FTO glass substrate of the counter electrode, a small hole with a diameter of 1 mm is first drilled through a glass puncher to facilitate the injection of the electrolyte. The subsequent cleaning process is like the cleaning process of the photoanode FTO glass substrate. After the ozone treatment, the FTO glass substrate of the counter electrode is calcined. The calcining process is to raise the temperature to 450° C. by program control, keep it for 15 minu...

Embodiment 3

[0048] Efficient TiO 2 Fabrication of photoanode dye-sensitized solar cells:

[0049] (1) Cleaning of photoanode FTO glass substrate and TiCl 4 Pre-processing:

[0050] The photoanodic FTO glass substrate was treated with detergent, deionized water, isopropanol, acetone and ultraviolet ozone for 15-120 minutes to obtain a clean surface. The cleaned FTO glass substrate was immersed in 0.04mol / L TiCl 4 In the aqueous solution, stand at 70°C for 30 minutes, and wash with distilled water and ethanol for 1 or 2 times. For the FTO glass substrate of the counter electrode, a small hole with a diameter of 1 mm is first drilled through a glass puncher to facilitate the injection of the electrolyte. The subsequent cleaning process is like the cleaning process of the photoanode FTO glass substrate. After the ozone treatment, the FTO glass substrate of the counter electrode is calcined. The calcining process is to raise the temperature to 450° C. by program control, keep it for 15 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com