Lithium-ion battery electrolyte and lithium ion battery with the same

A lithium-ion battery, electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of lithium-ion battery cycle capacity attenuation, aggravated transition metal element dissolution, and oxidative decomposition, etc., to improve cycle stability. , The effect of improving interface properties and reducing interface impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

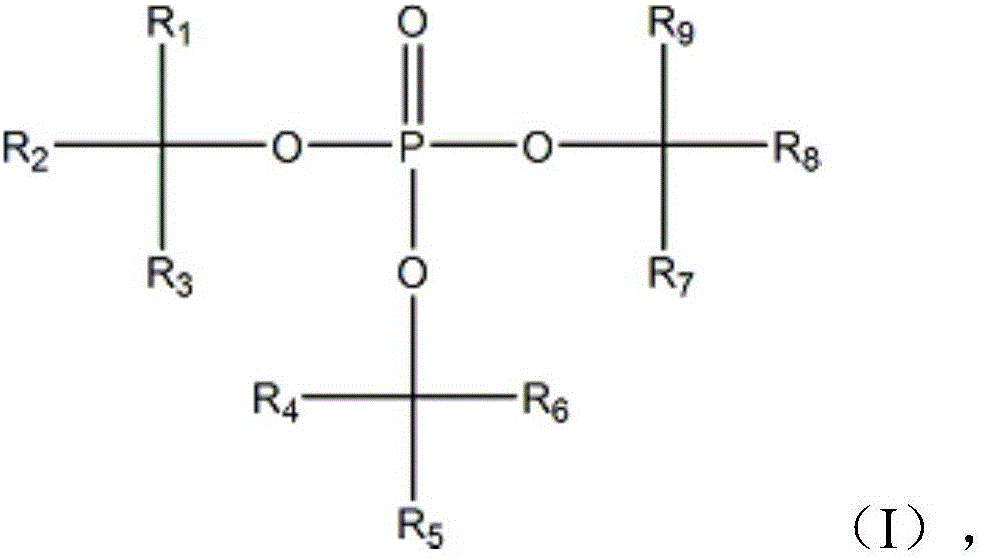

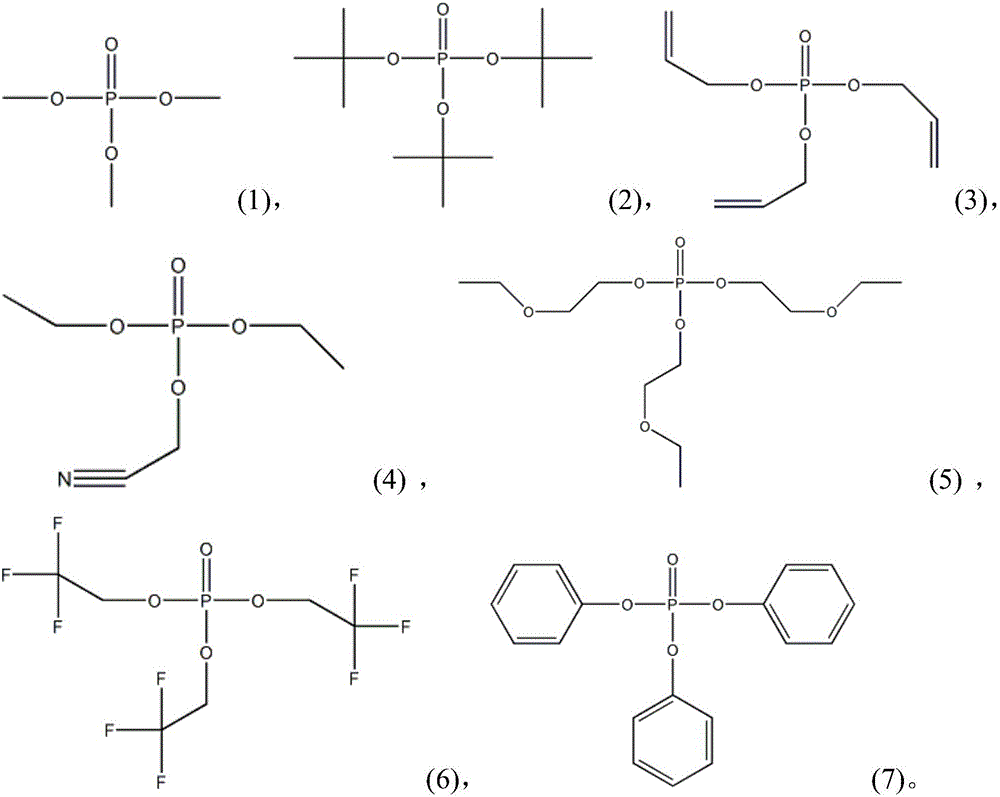

[0031] An electrolyte solution for a lithium-ion battery mainly includes an organic solvent, a conductive lithium salt and additives, and the additives include common additives and phosphate ester additives. The organic solvent is composed of ethylene carbonate and ethyl methyl carbonate, and the weight ratio of ethylene carbonate to ethyl methyl carbonate is EC:EMC=1:2. The conductive lithium salt LiPF 6 The concentration in the organic solvent is 0.8 mol / L, and the commonly used additives are vinylene carbonate and fluoroethylene carbonate, and the dosages are 1.0% and 2.0% respectively. The phosphate ester additive is trimethyl phosphate, and the dosage is 3.0wt.%.

[0032] The compound method of present embodiment electrolyte is:

[0033] (1) Mix the organic solvents in proportion and use them Molecular sieve, calcium hydride, lithium hydride purification, impurity removal, water removal;

[0034] (2) Dissolving the conductive lithium salt in the above-mentioned organ...

Embodiment 2

[0038] The preparation method of the electrolyte of this embodiment is the same as that of Embodiment 1, except that the solvent is ethylene carbonate and ethyl methyl carbonate, and the weight ratio is 1:3. The conductive lithium salt LiPF 6 The concentration in organic solvent is 1.0mol / L. The commonly used additives are vinylene carbonate and 1,3-propane sultone, and the dosages are 1.0% and 1.0% respectively. The phosphate ester additive is trimethyl phosphate, and the dosage is 5.0wt.%. The electrolytic solution prepared in this way is applied to LiNi according to the method identical with embodiment 1 0.8 co 0.15 Al 0.05 o 2 / Graphite flexible packaging battery, tested LiNi 0.8 co 0.15 Al 0.05 o 2 The cycle performance of graphite soft packaging battery at 3.0-4.2V, 1C rate charge and discharge at room temperature.

Embodiment 3

[0040] The preparation method of the electrolyte of this embodiment is the same as that of Embodiment 1, except that the solvent is ethylene carbonate and diethyl carbonate, and the weight ratio is 1:2. The conductive lithium salt LiPF 6 The concentration in organic solvent is 1.0mol / L. The commonly used additives are vinylene carbonate and fluoroethylene carbonate, and the dosages are 1.0% and 3.0% respectively. The phosphate ester additive is tri-tert-butyl phosphate, and the dosage is 0.5wt.%. The electrolytic solution prepared in this way is applied to LiNi according to the method identical with embodiment 1 0.5 co 0.2 mn 0.3 o 2 / Graphite flexible packaging battery, tested LiNi 0.5 co 0.2 mn 0.3 o 2 / The cycle performance of graphite flexible packaging battery at room temperature at 3.0-4.35V, 1C rate charge and discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com