Preparation method of boron-nitrogen dual-ingredient self-doping three-dimensional drape graphene electrode material

A graphene electrode and self-doping technology, which is applied in graphene, battery electrodes, chemical instruments and methods, etc., can solve the problems of harsh reaction equipment and reaction conditions, difficult doping methods and types, and cumbersome preparation process steps. Achieve the effects of easy realization of reaction conditions, easy control of doping amount and type, and simple reaction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

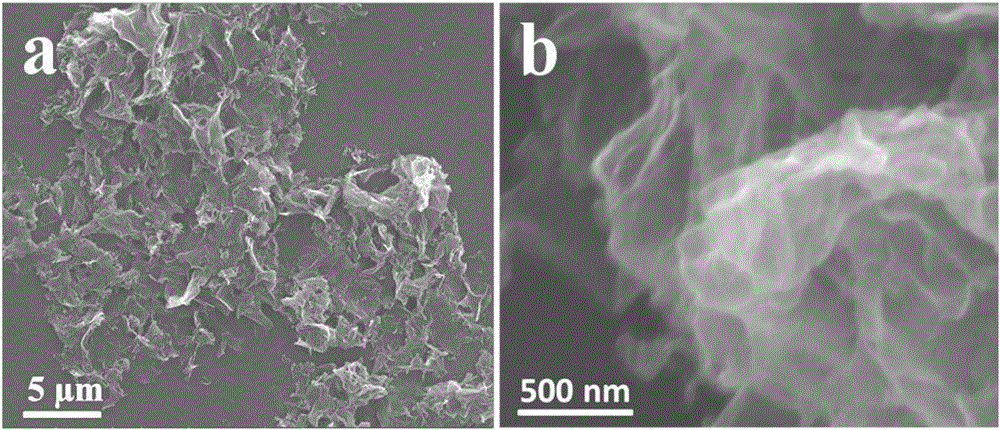

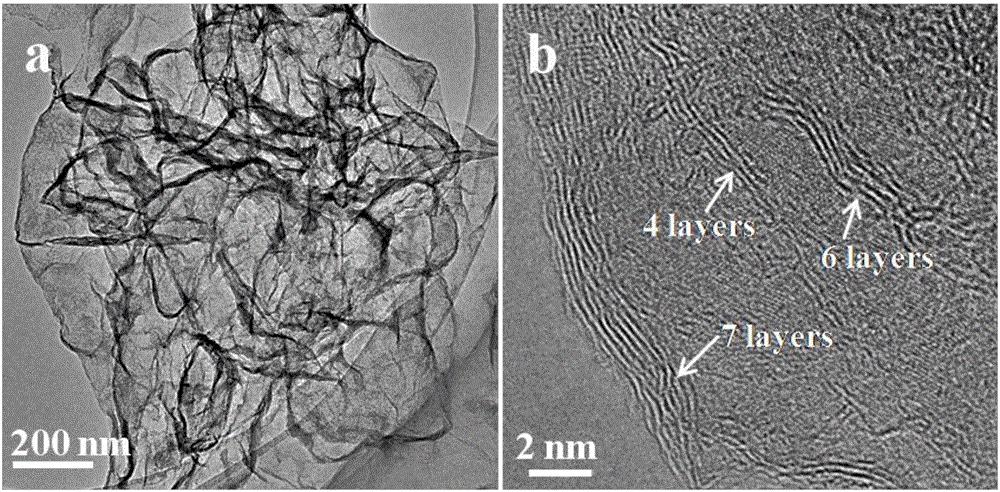

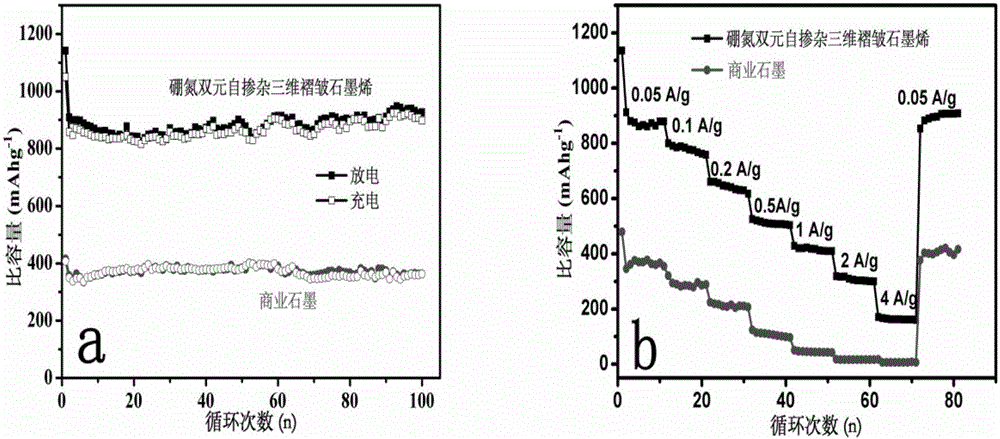

[0028] A method for preparing a boron-nitrogen binary self-doped three-dimensional wrinkled graphene electrode material, the operation steps are as follows:

[0029] (1) Mix 0.2 mol of borane-tert-butylamine complex with 0.1 mol of catalyst metal salt cobalt chloride, dissolve in 60 ml of ethanol, keep the temperature below 90° C., heat and stir until dry powder is obtained;

[0030] (2) heat-treating the dry powder obtained in step (1) at a temperature of 1000° C. for 1 hour in nitrogen, and then cooling to room temperature; wherein, the nitrogen gas introduced is to ensure that the heat treatment process is in an oxygen-free state;

[0031] (3) Add the substance obtained after cooling in step (2) to 500mL 3mol / L hydrochloric acid solution, heat and stir at 50°C for 8 hours, filter, wash the filter residue with deionized water until neutral, dry at 80°C for 24h, remove the residue in the filter residue Moisture, that is, boron and nitrogen binary self-doped three-dimensional ...

Embodiment 2

[0033] A method for preparing a boron-nitrogen binary self-doped three-dimensional wrinkled graphene electrode material, the operation steps are as follows:

[0034] (1) Mix 0.3 mol of trimethylamine-borane complex and 0.1 mol of catalyst metal salt cobalt sulfate, and dissolve in 60 ml of methanol, keep the temperature below 90°C and heat and stir until dry powder is obtained;

[0035] (2) Keeping the dry powder obtained in step (1) at a temperature of 800°C in argon for heat treatment for 3.5 hours, and then cooling to room temperature; wherein, the argon gas introduced is to ensure that the heat treatment process is an oxygen-free state;

[0036] (3) Add the substance obtained after cooling in step (2) to 500mL 3mol / L nitric acid solution, heat and stir at 35°C for 12 hours, filter, wash the filter residue with deionized water until neutral, dry at 80°C for 24 hours, remove the filter residue internal moisture, that is, boron and nitrogen binary self-doped three-dimensional...

Embodiment 3

[0038] A method for preparing a boron-nitrogen binary self-doped three-dimensional wrinkled graphene electrode material, the operation steps are as follows:

[0039] (1) 0.03mol trimethylamine-borane complex, 0.04mol dimethylaminoborane and 0.03mol borane ammonium complex with 0.01mol catalyst metal salt cobalt nitrate, 0.01mol acetic acid Cobalt, 0.02mol of ferric chloride, 0.01mol of ferric sulfate, 0.015mol of ferric oxalate, 0.025mol of ferric acetate, and 0.01mol of ferrous chloride were mixed and dissolved in 60ml of methanol and ethanol mixture (methanol+ethanol, volume Mixing ratio of 1:1), keep the temperature below 90°C, heat and stir until dry powder is obtained;

[0040] (2) Keeping the dry powder obtained in step (1) at a temperature of 1200° C. for heat treatment for 0.5 hours in hydrogen, and then cooling to room temperature; wherein, the hydrogen gas introduced is to ensure that the heat treatment process is in an oxygen-free state;

[0041] (3) Add the substa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com