Method for preparing carbon-based electrocatalyst from insect wing

A technology of electrocatalyst and wings, applied in the field of preparing carbon-based electrocatalysts from insect wings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

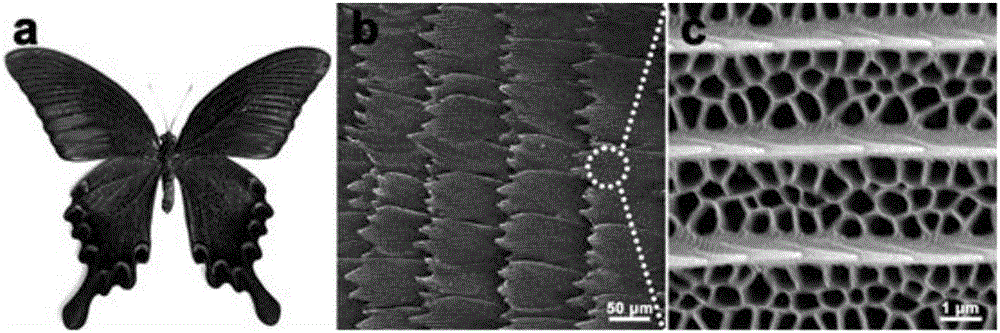

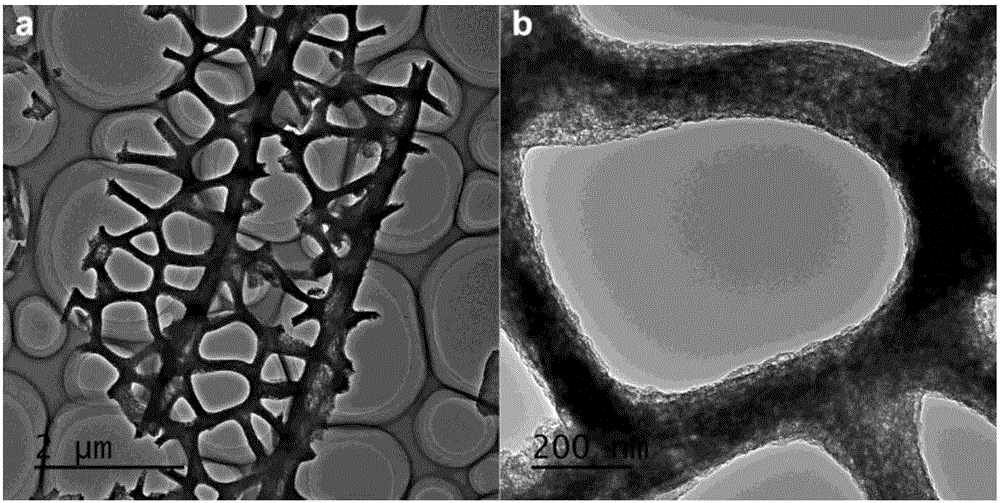

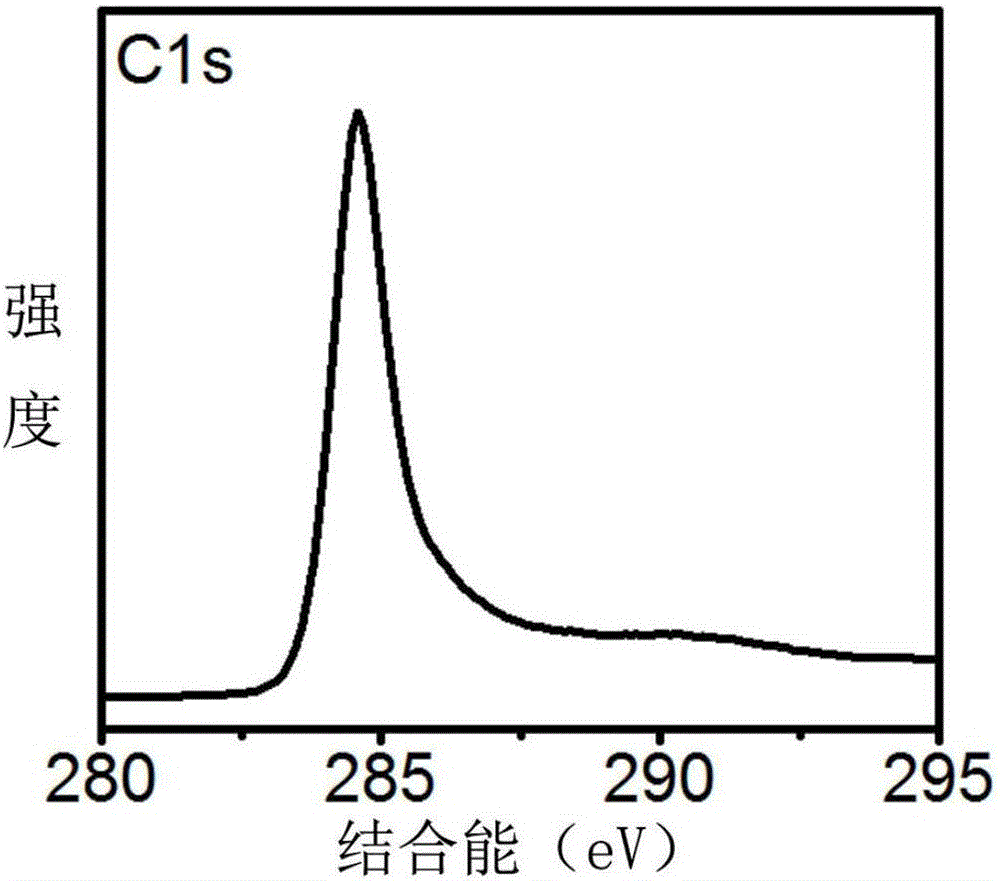

[0037] The insect species is the green-banded Papilio, the nitrogen source is ammonia, and the nitrogen doping amount is 2at%.

[0038] A method for preparing a carbon-based electrocatalyst using the wings of the green-banded phoenix butterfly as a raw material, the steps are as follows:

[0039] (1) Take eight pieces of wings (about 0.14g) of the green-banded phoenix butterfly, put them into a hot kettle with 40mL of deionized water, and conduct a hydrothermal reaction in an oven at 100°C for 2 hours. After cooling to room temperature, take out the wings , placed in a 60°C oven for drying;

[0040] (2) Weigh an appropriate amount of dried wings in step (1) and immerse them in dissolved absolute ethanol, then put them into a lyophilizer, and freeze and dry them in a vacuum at minus 80°C for 48 hours;

[0041] (3) Put the freeze-dried wings in step (2) into a crucible, calcinate in a tube furnace at 1000°C for 2 hours in an atmosphere mixed with ammonia and nitrogen, and then ...

Embodiment 2

[0059] The invention discloses a method for preparing a carbon-based electrocatalyst by using butterfly wings as a raw material, and the insect species is Nebula yellow butterfly.

[0060] The preparation method of the electrocatalytic material is basically the same as that of Example 1, except that the green-banded phoenix butterfly in the step (1) is replaced by the yellow phoenix butterfly.

[0061] Figure 12 It is the oxygen reduction polarization curve of the carbon-based electrocatalyst prepared by P. japonica. It can be seen that the peak potential of the catalyst is 0.992V, and the half-wave potential is 0.907V.

Embodiment 3

[0063] The invention discloses a method for preparing a carbon-based electrocatalyst by using butterfly wings as a raw material, and the insect species is Japanese nymph.

[0064] The preparation method of the electrocatalytic material is basically the same as that of Example 1, except that: the green-banded papilio in step (1) is replaced by the Japanese nymph.

[0065] Figure 13 It is the oxygen reduction polarization curve of the carbon-based electrocatalyst prepared by the Japanese nymph. It can be seen that the onset potential of the catalyst is 0.987V, and the half-wave potential is 0.902V.

[0066] Example 3

[0067] The invention discloses a method for preparing a carbon-based electrocatalyst by using butterfly wings as raw materials, and the insect species is map nymph.

[0068] The preparation method of the electrocatalytic material is basically the same as that of Example 1, except that the green-banded Swallowtail in step (1) is replaced by the map nymph.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com