Dielectric composite material based on paraffin-coated barium titanate nanoparticles and preparation method thereof

A nano-particle and barium titanate-coated technology, which is applied in the field of dielectric composite materials and its preparation, can solve the problems of uneven mixing, poor compatibility between ceramic phase and polymer matrix, etc., and achieve excellent mechanical properties and few defects , Excellent film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

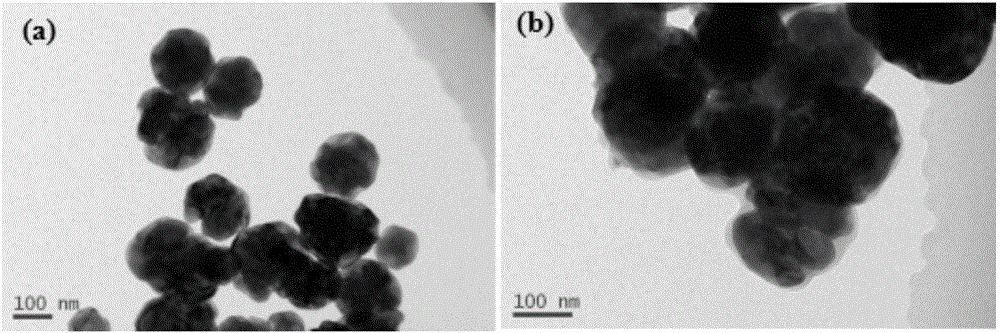

[0040] Hydroxylated barium titanate spherical nanoparticles coated with paraffin

[0041] Weigh 10.0 g of barium titanate spherical nanoparticles and disperse them into a 95:5 (v / v) ethanol / water mixed solution, stir and sonicate, collect the precipitate by centrifugation, and dry it in vacuum. Use H 2 o 2 The aqueous solution oxidizes barium titanate spherical nanoparticles to increase the hydroxyl content on its surface. The specific process is to add 100ml 30wt% H 2 o 2 and 10 g of barium titanate spherical nanoparticles, ultrasonically dispersed for 30 min, and then refluxed at 106 ° C for 6 h and kept stirring. After the reaction, cool down to room temperature, transfer the suspension to a 50ml centrifuge tube, and centrifuge at a speed of 9000r / min for 5min. After the centrifugation, pour the liquid in the upper layer, add deionized water, repeat washing twice, and place in the Dry in a vacuum oven at 80°C for 12 hours. Disperse 8.0 g of hydroxylated barium titanate...

Embodiment 2

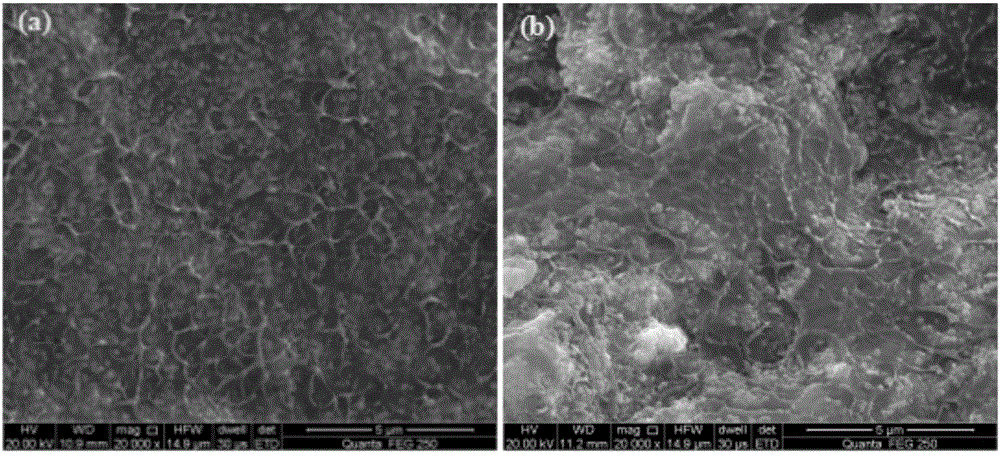

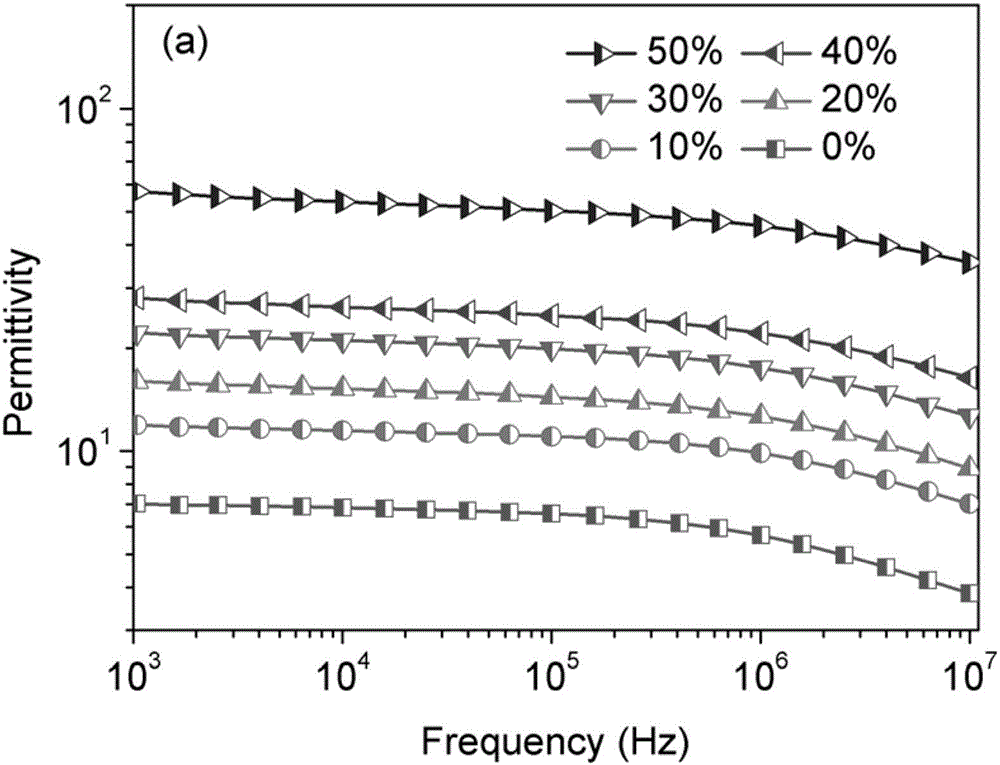

[0043] Preparation of paraffin-coated barium titanate spherical nanoparticles (prepared in Example 1) and P(VDF-HFP) dielectric composite material;

[0044] First configure the P(VDF-HFP) solution of 8wt%, take by weighing 8g of P(VDF-HFP) resin particles, join in the mixed solvent that 92g prepares (V 丙酮 :V DMF =7:3), stirred at 60°C until it was completely dissolved and became a transparent solution. An appropriate amount of paraffin-coated barium titanate spherical nanoparticles was weighed and added to the P(VDF-HFP) solution to form mixed solutions with volume fractions of 10, 20, 30, 40 and 50 vol%, respectively, and stirred for 24 hours. Then the stirred suspensions were poured and casted on glass plates, dried at 80°C to form a film, and the obtained composite film was hot-pressed at 200°C and 15Mpa using a flat vulcanizer to form a dense composite film. Design a metal mask with a circular hole diameter of 2 mm and a hole center spacing of 4 mm. The shape of the meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com