Method for extraction of vanadium from waste SCR catalyst and preparation of activated titanium silicon tungsten powder

An SCR catalyst, titanium silicon tungsten technology, applied in the field of waste catalyst recycling, can solve problems such as low cost, achieve the effects of low price, reduce consumption, and overcome sodium ion pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

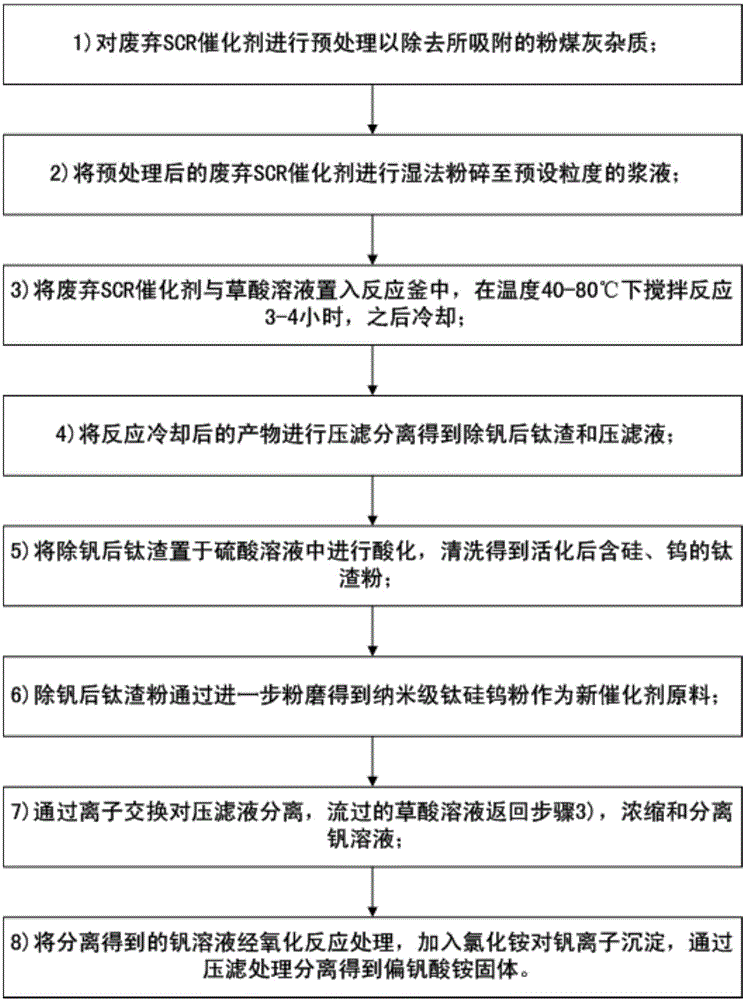

[0058] 1) Carry out pretreatment to waste SCR catalyst to remove the impurity that is adsorbed; Said pretreatment includes carrying out water shower and soaking, ultrasonic cleaning, acidification and water washing treatment to waste SCR catalyst; Poisoning elements such as potassium, sodium and arsenic are cleaned, and the functions of titanium dioxide and tungsten trioxide are initially restored. The impurities are fly ash and coke.

[0059] 2) wet crushing the pretreated waste SCR catalyst to a slurry with a predetermined particle size; the slurry formed by the wet crushing is a slurry with a particle size of 180 mesh.

[0060] 3) Add an oxalic acid solution with a concentration of 4% (mass volume ratio) to the slurry, and the mass ratio of the waste SCR catalyst to the oxalic acid solution is 1:4, stir and react in a reaction kettle at a temperature of 80°C for 3-4 hour, so that the vanadium pentoxide component is dissolved into vanadyl oxalate to achieve the purpose of v...

Embodiment 2

[0074] This embodiment provides a method for extracting vanadium from waste SCR catalysts to prepare activated titanium-silicon-tungsten powder similar to that of Embodiment 1, which specifically includes the following steps:

[0075] 1) Carry out pretreatment to waste SCR catalyst to remove the impurity that is adsorbed; Said pretreatment includes carrying out water shower and soaking, ultrasonic cleaning, acidification and water washing treatment to waste SCR catalyst; Poisoning elements such as potassium, sodium and arsenic are cleaned, and the functions of titanium dioxide and tungsten trioxide are initially restored. The impurities are fly ash and coke.

[0076] 2) wet crushing the pretreated waste SCR catalyst to a slurry with a certain particle size, for example, a slurry with a particle size of 325 mesh;

[0077] 3) Add an oxalic acid solution with a mass percentage concentration of 9% (mass volume ratio) to the slurry, and the mass ratio of the waste SCR catalyst to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com