Preparation method of nano gallium nitride spherical powder

A spherical powder, gallium nitride powder technology, applied in the field of preparation of gallium nitride nanoparticles, can solve the problems of low target density, low preparation efficiency, poor fluidity and dispersibility, etc., and achieve optimized particle size distribution , Eliminate the powder agglomeration, the effect of excellent dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, 20g particle diameter is 1-20 μ m, and purity is > 99.99% gallium oxide powder (such as figure 1 shown) into a microwave heating furnace full of ammonia for nitriding treatment, the process parameters are: the flow rate of ammonia gas is 5 standard liters / min, the power of the microwave heating furnace is 1kW, the reaction temperature is 900°C, and the reaction time is 3h.

[0029] The gallium nitride powder obtained by the reaction was put into a ball mill jar, ball milled for 5 minutes at a speed of 100 r / min, and vibratingly sieved with a 500-mesh screen.

[0030] The gallium nitride powder obtained by sieving is subjected to nano-processing, and the nano-processing parameters are

[0031] Table 1 Process parameters of induction plasma preparation of nano-gallium nitride

[0032]

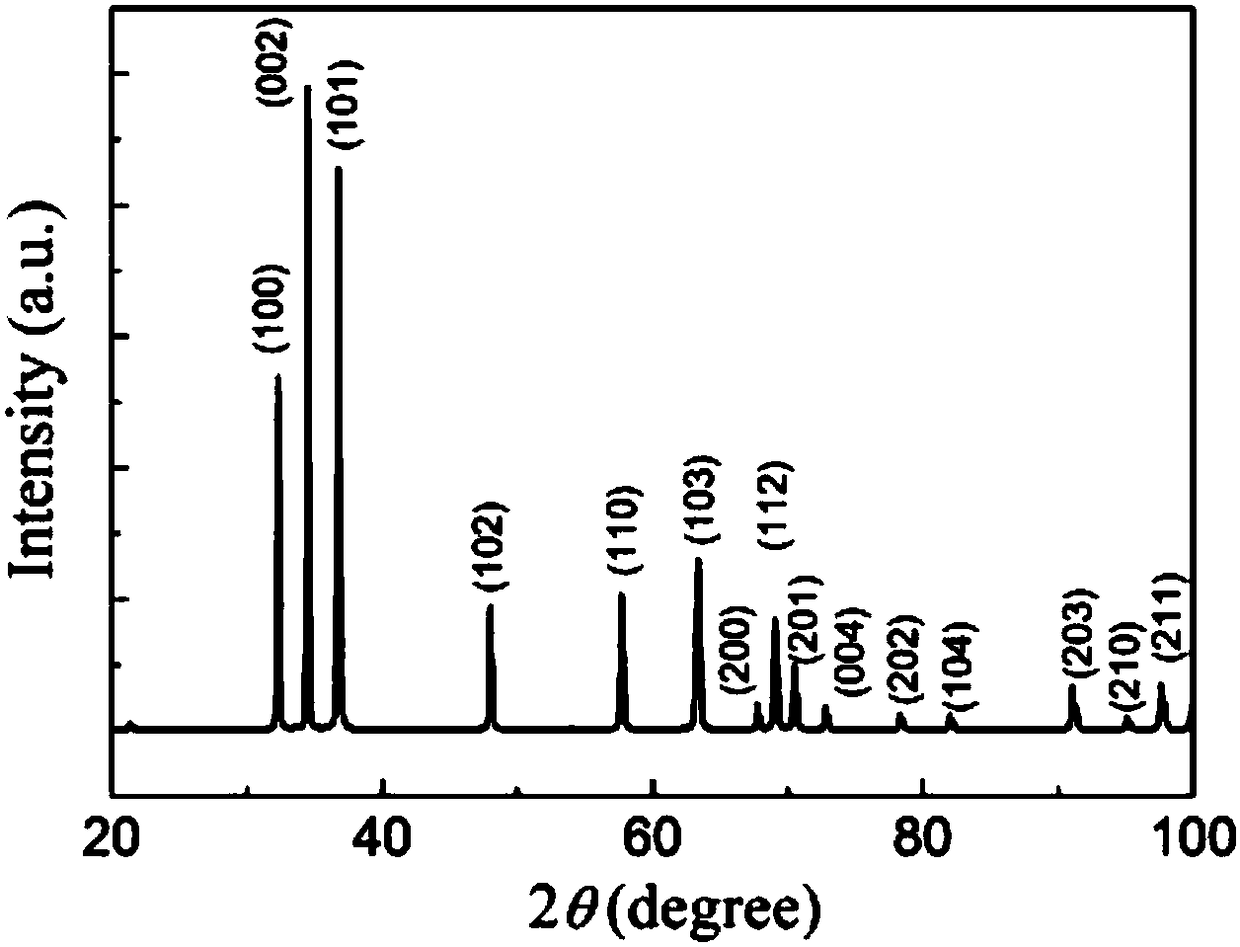

[0033] figure 2 It is the SEM photo of the nano-gallium nitride spherical powder prepared by using the above process parameters. image 3 It is the XRD spectrum of the...

Embodiment 2

[0035] Example 2, put 20 g of gallium oxide powder with a particle size of 1-20 μm and a purity of >99.99% for nitriding treatment in a microwave heating furnace filled with ammonia gas. The process parameters are: the flow rate of ammonia gas is 3 standard liters / minute, The power of the microwave heating furnace is 3kW, the reaction temperature is 1100°C, and the reaction time is 2h.

[0036] The gallium nitride powder obtained by the reaction was put into a ball mill jar, and ball milled for 3 minutes at a speed of 200 r / min, and then vibratingly sieved by using a 325-mesh sieve.

[0037] The gallium nitride powder obtained by sieving is subjected to nano-processing, and the nano-processing parameters are

[0038] Table 2 Process parameters of induction plasma preparation of nano-gallium nitride

[0039]

[0040] The microwave heating furnace in this embodiment adopts the microwave oven of Longtai Microwave Thermal Engineering Co., Ltd. model as Hamilab-HV6, and the ind...

Embodiment 3

[0041] Example 3, put 20 g of gallium oxide powder with a particle size of 1-20 μm and a purity of >99.99% for nitriding treatment in a microwave heating furnace filled with ammonia gas. The process parameters are: the flow rate of ammonia gas is 1 standard liter / min, The power of the microwave heating furnace is 6kW, the reaction temperature is 1200°C, and the reaction time is 1h.

[0042] The gallium nitride powder obtained by the reaction was put into a ball mill jar, ball milled for 1 min at a speed of 300 r / min, and vibratingly sieved with a 200-mesh screen.

[0043] The gallium nitride powder obtained by sieving is subjected to nano-processing, and the nano-processing parameters are

[0044] Table 3 Process parameters of induction plasma preparation of nano-gallium nitride

[0045]

[0046]The microwave heating furnace in this embodiment adopts the microwave heating furnace of Longtai Microwave Thermal Engineering Co., Ltd. model as Hamilab-HV6, and the induction pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com