High-performance piezoceramic material and preparation method thereof

A piezoelectric ceramic, high-performance technology, applied in the field of piezoelectric ceramics, can solve the problems of reducing material reliability, reducing piezoelectric performance, low fracture toughness, etc., and achieve the effect of improved fracture toughness, high bending strength, and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A high-performance piezoelectric ceramic material is prepared from the following raw materials in parts by weight:

[0032] 34 parts of titanium tetrachloride, 3 parts of silver vanadate, 11 parts of barium nitrate, 5 parts of glutamic acid, 2 parts of scandium acetate, 4 parts of lithium tetrachloroaluminate, 3 parts of sodium silicon zirconate, 5 parts of terbium triacetate hydrate , 4 parts of vanadium copper oxide, 1 part of gallium telluride, 4 parts of phosphorus oxide, 6 parts of lithium tantalate, 3 parts of magnesium niobate, 2 parts of potassium chlorate, 4 parts of nickel citrate, 26 parts of methanol, 15 parts of deionized water, 30 parts of ethylene glycol.

[0033] The preparation method of the above-mentioned high-performance piezoelectric ceramic material includes the following preparation steps:

[0034] Step 1) Put glutamic acid in a mixed solution of methanol and deionized water, stir to dissolve, then add titanium tetrachloride, silver vanadate, ter...

Embodiment 2

[0043] A high-performance piezoelectric ceramic material is prepared from the following raw materials in parts by weight:

[0044] 50 parts of titanium tetrachloride, 9 parts of silver vanadate, 20 parts of barium nitrate, 9 parts of glutamic acid, 6 parts of scandium acetate, 10 parts of lithium tetrachloroaluminate, 9 parts of sodium silicon zirconate, 9 parts of terbium triacetate hydrate , 8 parts of vanadium copper oxide, 6 parts of gallium telluride, 9 parts of phosphorus oxide, 10 parts of lithium tantalate, 8 parts of magnesium niobate, 7 parts of potassium chlorate, 10 parts of nickel citrate, 38 parts of methanol, 22 parts of deionized water, 43 parts of ethylene glycol.

[0045] The preparation method of the above-mentioned high-performance piezoelectric ceramic material includes the following preparation steps:

[0046] Step 1) Put glutamic acid in a mixed solution of methanol and deionized water, stir to dissolve, then add titanium tetrachloride, silver vanadate,...

Embodiment 3

[0055] A high-performance piezoelectric ceramic material is prepared from the following raw materials in parts by weight:

[0056] 38 parts of titanium tetrachloride, 4 parts of silver vanadate, 13 parts of barium nitrate, 6 parts of glutamic acid, 2.8 parts of scandium acetate, 4.5 parts of lithium tetrachloroaluminate, 3.2 parts of sodium silicon zirconate, 5.3 parts of terbium triacetate hydrate , 4.6 parts of vanadium copper oxide, 2 parts of gallium telluride, 4.5 parts of phosphorus oxide, 6.2 parts of lithium tantalate, 3.5 parts of magnesium niobate, 2.4 parts of potassium chlorate, 4.8 parts of nickel citrate, 32 parts of methanol, 16 parts of deionized water, 32 parts of ethylene glycol.

[0057] The preparation method of the above-mentioned high-performance piezoelectric ceramic material includes the following preparation steps:

[0058] Step 1) Put glutamic acid in a mixed solution of methanol and deionized water, stir to dissolve, then add titanium tetrachloride, s...

PUM

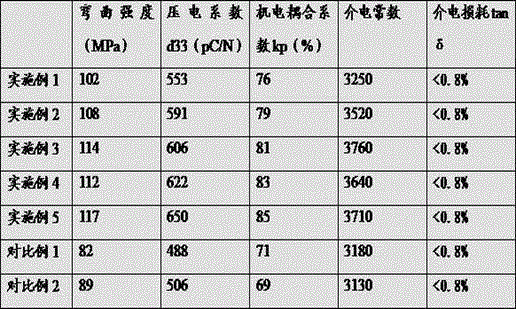

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| electromechanical coupling coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com