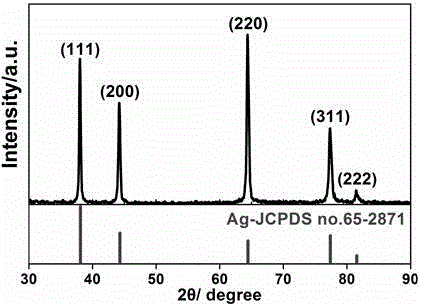

Method for preparing micro-nano-porous silver based on eutectic flux in-situ alloy deposition/alloy removing method

A technology of in-situ deposition and dealloying, which is applied in the direction of nanotechnology, can solve problems such as equipment corrosion, complicated process, and high energy consumption, and achieve the effects of mild reaction conditions, simple process, and low energy consumption for reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

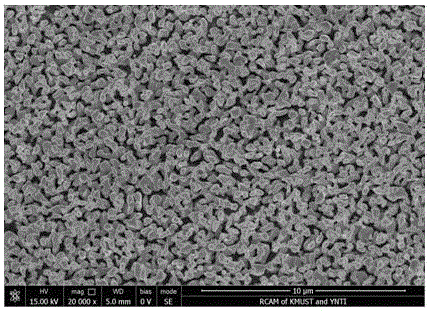

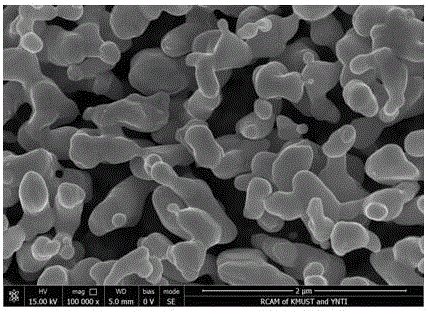

[0024] The method for preparing micro-nano porous silver based on in-situ deposition alloying / dealloying method of eutectic flux, its specific steps are as follows:

[0025] (1) In an open system, mix the quaternary ammonium salt after vacuum drying at 80°C with the hydrogen bond donor at a molar ratio of 1:2, and then react for 1 hour at a constant temperature of 80°C to prepare the eutectic Ionic liquid; adding a metal-inducing salt to the eutectic ionic liquid and mixing uniformly to obtain a eutectic ionic liquid-metal salt composite electrolyte; wherein the quaternary ammonium salt is choline chloride, and the hydrogen bond donor is ethylene glycol; The metal inducing salt is zinc chloride, and its concentration is 0.10 mol / L eutectic ionic liquid;

[0026] (2) With the silver sheet (2.0cm×1.5cm×0.1cm) as the cathode and the graphite sheet as the anode, in the ionic liquid-metal salt composite electrolyte obtained in step (1) at a temperature of 100°C and an electrode spa...

Embodiment 2

[0030] The method for preparing micro-nano porous silver based on in-situ deposition alloying / dealloying method of eutectic flux, its specific steps are as follows:

[0031] (1) In an open system, mix the quaternary ammonium salt after vacuum drying at 80°C with the hydrogen bond donor at a molar ratio of 1:2, and then react for 1 hour at a constant temperature of 80°C to prepare the eutectic Ionic liquid; adding a metal-inducing salt to the eutectic ionic liquid and mixing uniformly to obtain a eutectic ionic liquid-metal salt composite electrolyte; wherein the quaternary ammonium salt is choline chloride, and the hydrogen bond donor is ethylene glycol; The metal inducing salt is zinc chloride, and its concentration is 0.10 mol / L eutectic ionic liquid;

[0032] (2) With the silver sheet (2.0cm×1.5cm×0.1cm) as the cathode and the graphite sheet as the anode, in the ionic liquid-metal salt composite electrolyte obtained in step (1) at a temperature of 100°C and an electrode spa...

Embodiment 3

[0036] The method for preparing micro-nano porous silver based on in-situ deposition alloying / dealloying method of eutectic flux, its specific steps are as follows:

[0037] (1) In an open system, mix the quaternary ammonium salt after vacuum drying at 80°C with the hydrogen bond donor at a molar ratio of 1:2, and then react for 1 hour at a constant temperature of 80°C to prepare the eutectic Ionic liquid; adding a metal-inducing salt to the eutectic ionic liquid and mixing uniformly to obtain a eutectic ionic liquid-metal salt composite electrolyte; wherein the quaternary ammonium salt is choline chloride, and the hydrogen bond donor is ethylene glycol; The metal inducing salt is zinc chloride, and its concentration is 0.10 mol / L eutectic ionic liquid;

[0038] (2) With the silver sheet (2.0cm×1.5cm×0.1cm) as the cathode and the graphite sheet as the anode, in the ionic liquid-metal salt composite electrolyte obtained in step (1) at a temperature of 100°C and an electrode spa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com